Tetramethylammonium Bromide: A Deep Dive

Historical Development

Chemists began exploring quaternary ammonium compounds in the late 19th century. Tetramethylammonium bromide (TMAB) entered laboratory shelves as researchers examined new catalysts and phase transfer agents. Its easy and distinct synthesis, paired with growing demand, attracted both academic and industrial attention through the 20th century. The journey from benchwork curiosity to widespread reagent followed the expansion of synthetic organic chemistry. Teams in Europe and the United States regularly tested its physical and chemical roles, running experiments that helped define much of what we know about related ammonium salts today. The steady march of scientific inquiry gave TMAB a reputation for reliability and safety among skilled practitioners. If you ever worked in a well-equipped organic chemistry lab you probably brushed past this crystalline salt, stored in humidity-proof containers on a high shelf.

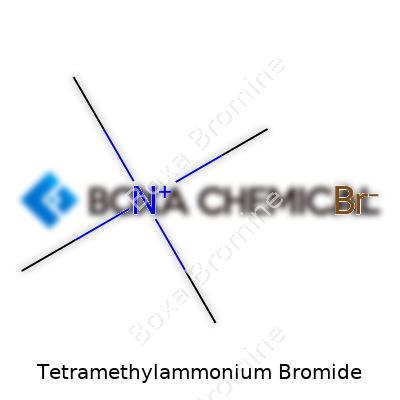

Product Overview

TMAB offers a structure that features a positively charged nitrogen atom surrounded by four methyl groups, with a bromide anion keeping things balanced. Its chemical formula—C4H12NBr—breaks down into understandable pieces, even for those getting started in chemical studies. TMAB’s status as a quaternary ammonium compound means it appears regularly in chemical catalogs that support research, pharmaceuticals, and specialty processes. Companies produce and package it with a range of purities, depending on the target market, from technical work to demanding analytical applications. Veteran chemists associate this product with the clear, white, odorless crystals contained in tightly sealed jars that line the reference shelves in synthesis labs across the globe.

Physical & Chemical Properties

This compound catches the eye for its solid form and snow-white color. A close look shows a material that resists absorbing water from the air, which distinguishes it from more hygroscopic salts. TMAB dissolves easily in water and alcohols, making it a cooperative partner in solution chemistry. Its melting point lands near 233°C. Handlers note its lack of a strong smell and its ability to stay stable under typical storage and work conditions. You can pour it into a flask and expect predictability—no sudden decomposition or volatility to worry about. The bromide anion stays balanced with the organic cation, delivering a material that sets standards for purity and shelf life in academic, pharmaceutical, and industrial spaces.

Technical Specifications & Labeling

You’ll find TMAB sold under batch labels marked with CAS number 64-20-0, grade, and purity. Labs choose between analytical reagent grade, lab grade, or highly purified product based on their goals. Labels show moisture content, melting point, and residual acidity or alkalinity, since these small details matter in many reactions. Color-coded hazard statements and GHS-compliant icons keep safety in view for those handling the bags and jars daily. Experienced personnel expect these bottles to feature lot numbers, expiry dates, and clear indications of the manufacturer, ensuring full traceability for research audits and regulatory reviews.

Preparation Method

TMAB synthesis requires adding methyl groups to ammonia using methyl iodide, followed by exchange of iodide for bromide. Commercial processes operate on a much larger scale, deploying batch reactors with stirring and controlled cooling. During laboratory preparations, workers combine trimethylamine with methyl bromide under controlled temperature and pressure, followed by careful crystallization to pull TMAB out of the reaction mixture. This purification step uses repeated washing and filtration to remove possible side products. The final crystals dry under vacuum, giving the pure, dry salt ready for use and storage.

Chemical Reactions & Modifications

TMAB rarely sits idle. Its most well-known role appears in phase-transfer catalysis, where it ferries reactants between water and organic solvents, smoothing the progress of alkylation or oxidation reactions. In my own postgraduate synthesis work, swapping chloride for bromine in specific reactions relied on TMAB’s ability to dissolve in both phases. Its quaternary ammonium structure also means you can tailor the performance by swapping methyl groups for longer alkyl chains and swapping bromide for other halide anions, letting chemists fine-tune reactivity and selectivity. TMAB's knack for stable performance under both acidic and basic conditions makes it dependable for challenging reactions such as nucleophilic substitutions, etherifications, or certain types of functional group conversions.

Synonyms & Product Names

TMAB goes by a handful of names that reflect its structure: Tetramethylamine bromide, N,N,N-Trimethylmethanaminium bromide, and simply TMA bromide. Chemical suppliers track it using the industry-standard CAS number. Reagents, technical catalogs, and laboratory procurement orders include these identifiers to help professionals secure the correct material for critical procedures, whether in synthesis, analytical work, or pilot plant production.

Safety & Operational Standards

Handling TMAB doesn’t call for unusual protocols but responsible labs follow safety guidelines. Gloves and goggles protect against accidental contact, and fume hoods ensure any fine particles don’t become airborne. The main occupational concern lies in avoiding dust inhalation or eye contact, so experienced workers prefer weighing and transferring under localized ventilation. Storage away from acids and strong oxidizers keeps everyone protected. Regulatory rules from OSHA and local agencies include TMAB among substances requiring proper training, inventory control, and emergency protocols for spills or accidental exposure.

Application Area

TMAB turns up in dozens of research papers and patent filings. Water treatment engineers use it as a phase-transfer agent for environmental chemistry. Electronics technicians employ it for etching and developing processes due to its stability and solubility profile. Pharmaceutical chemists draw on its properties for producing quaternary ammonium drugs or intermediates, especially where bromide leaving groups play a part. Researchers in spectroscopy and chromatography appreciate its consistency for preparing buffers or electrolytes. Polymers teams add TMAB to influence polymerization reactions, and academic groups rely on its performance for teaching and basic studies. In my graduate research, TMAB took part in experiments tweaking alkylation selectivity, and its reliable solubility always made for clear results.

Research & Development

Active studies test novel uses for TMAB, stretching into green chemistry and advanced materials. Academics and industrial labs pursue new applications as ionic liquids or for developing room-temperature molten salts. Work continues on improved phase-transfer catalysis, using TMAB to leapfrog older, less effective methods. Ongoing R&D examines how subtle changes in the structure of TMAB analogs influence activity, selectivity, and environmental footprint. Scientists look for ways to enhance effectiveness while reducing waste and hazard—driven by pressure for greener, more efficient chemical processes.

Toxicity Research

Workers in toxicology labs have probed the safety profile of TMAB. Moderate toxicity emerges in animal models at higher doses, with most acute effects due to bromide accumulation or disruption of neurotransmitter balance. Careful risk assessments gave regulators confidence to allow laboratory use, with limits for chronic exposure and special instructions for disposal. Human reports of accidental exposure involve mild irritation or digestive discomfort, but these happen rarely in modern labs thanks to improved training and PPE. Key findings highlight low volatility, limited skin penetration, and a manageable risk profile compared to more reactive quaternary ammonium compounds. Researchers continue examining chronic and long-term effects, particularly as demand expands in new application fields.

Future Prospects

TMAB stands poised for greater roles across several growing industries. Ongoing work in rechargeable batteries, advanced electrolytes, and ionic liquids points to this compound as a potential building block for next-generation materials. Sustainable processes look to TMAB as a safer alternative to harsher agents and as a partner for green synthetic methods. As new regulatory demands focus attention on environmental impact, TMAB’s established record of stability and relative safety positions it as a preferred choice for many critical reactions. The chemistry community continues exploring smarter derivatives, more selective catalysis, and broader uses in life sciences and electronics. Based on its pedigree and practical versatility, TMAB remains a cornerstone for researchers and industrial teams determined to shape the future of specialty chemicals.

What It Does in the Real World

Tetramethylammonium bromide often pops up in chemistry textbooks, but real-life uses tell a bigger story. Chemists usually look at it as a phase-transfer catalyst, speeding up reactions that would normally crawl along at a snail’s pace. Phase-transfer catalysts work by moving reactants between liquid phases, like oil and water. In practice, this means processes that piggyback on tetramethylammonium bromide can run faster and use less energy. Industries appreciate these savings, especially as electricity bills and environmental pressure grow.

Over the years in the lab, watching tetramethylammonium bromide at work made it clear how much it matters in making both simple and complex organic compounds. Synthesis of pharmaceuticals, dyes, and specialty chemicals often relies on its efficiency. An experienced chemist counts on its reliability. For instance, drug researchers use it for reactions where two ingredients usually refuse to mix. Without it, yields would flop, and costs would jump up.

Everyday Tech Relies on Solid Chemistry

It doesn’t just stay behind closed doors in research labs. Manufacturers use tetramethylammonium bromide to help shape electronics. In the semiconductor industry, this compound helps etch intricate patterns onto microchips. Over the years, electronics have grown smaller and quicker, raising the stakes for chemical precision. In these clean rooms, purity rules. Contamination throws off entire productions worth millions, and only compounds with trusted records get the green light.

Environmental and Safety Hurdles

Every tool comes with trade-offs. Tetramethylammonium bromide, despite its perks, raises environmental and safety questions. While it serves as a handy chemical, it’s toxic in high doses, affecting aquatic life and human health if released improperly. People working in factories or labs follow strict guidelines, don gloves, and use fume hoods to reduce exposure. More regulations call for safer disposal and alternatives, especially in industries flush with waste streams.

Stepping outside the lab, local waterways and landfill sites offer reminders of what happens when leftover chemicals get dumped. Real-life incidents with improper disposal underline the need for responsible management. Years ago, a research group I worked with ran a waste review. We found half-used stock bottles dating back decades—striking evidence of how easy it is to forget what happens to chemicals after experiments wrap up. That experience inspired ongoing controls, aiming to use less product and recycle where possible.

Pushing Toward Better Solutions

Some companies invest in research to find greener, less hazardous options. The shift takes cash, patience, and creativity. Still, the push has already led to new catalysts with similar effectiveness but fewer environmental downsides. On a practical level, regular training reminds lab workers to handle these compounds with respect and double-check waste labels. Schools and businesses can team up to share resources for safe chemical disposal. For smaller labs, working with local governments on subsidies helps handle costs.

Thinking about tetramethylammonium bromide isn’t just for chemists. The way society deals with specialty chemicals affects food safety, clean water, and technology. Small changes, from better training to better waste tracking, start making a difference you can measure outside the lab as well as inside.

Why People Work with Tetramethylammonium Bromide

Chemists and researchers use Tetramethylammonium Bromide, often called TMAB or TMABr, in a range of lab procedures. It finds its way into DNA extraction protocols, phase-transfer catalysis, and even in some pharmaceutical research. With a formula that brings together the tetramethylammonium cation and bromide anion, this white powder looks harmless at first glance. Looks, though, don’t always tell the real story.

Toxicity and Exposure Risks

Several lab safety datasheets point out risks linked to Tetramethylammonium Bromide. Swallowing a small amount causes harmful effects—tingling, tremors, nausea, or worse. The compound affects the nervous system, producing symptoms similar to nicotine at a biochemical level. Even skin contact or inhalation causes irritation or toxic reactions, making direct handling a bad idea.

A study from the Journal of Applied Toxicology shows that exposure to small amounts of TMAB causes significant effects in mice—muscle weakness, difficulty breathing, and, with enough exposure, death. These findings match up with scattered case reports of human exposure in research settings. No one wants to rush a coworker to the hospital after a simple mixing mistake, but that risk stays real in labs that don’t take precautions.

Personal Experience in the Lab

Working through grad school, I had a stint in a molecular biology lab with regular TMAB use. Handling it always meant gloves, goggles, and a crowded bench full of warning signs. One slip-up with powder and my hands tingled for hours; nobody ignored the chemical’s reputation after that. Our lab manager drilled into us the importance of working inside a fume hood, sealing waste promptly, and keeping spills off skin.

Mistakes did happen. Someone once pipetted TMAB solution too quickly, sent it spraying, and we locked down the bench to sanitize. Luckily, proper protocols kept the worst from happening. It became clear that those safety rules serve a purpose. Hazards in the real world become all too obvious when you see effects on a friend, not just a page in a textbook.

The Bigger Picture—Safety Beyond the Lab

While Tetramethylammonium Bromide isn’t showing up in consumer products or over-the-counter solutions, its role in research laboratories and industry keeps growing. The lack of widespread public awareness does not mean a lack of risk. Agencies like the National Institute for Occupational Safety and Health and PubChem advise strong personal protective equipment, immediate decontamination after spills, and training tailored to chemical hazards.

Anyone storing or discarding TMAB needs clear labeling and disposal practices. It breaks down to toxic substances in the environment, sometimes releasing hazardous bromides, so improper disposal becomes a community hazard, not just a lab worker’s issue.

Addressing the Issue: Precaution and Training

The solutions start with education. Regular training keeps lab workers alert. Updated safety protocols, clear labeling, and reported incidents make a difference. Using less hazardous alternatives, when possible, goes a long way. Fume hoods, emergency eyewash stations, and gloves remain the front line. By staying honest about risks and open about near-misses, the research community keeps everyone safer.

Tetramethylammonium Bromide won’t disappear from labs anytime soon, but respect for its dangers builds the culture of safety science relies on.

Breaking Down That Name

The chemical world throws a lot of long names at us, and Tetramethylammonium Bromide feels like one that belongs in textbooks or dusty lab reports. Strip away the layers, the formula it boils down to is (CH3)4NBr. This formula tells exactly what the compound is: four methyl groups stuck to a nitrogen, with a bromide tagging along. Personally, my first encounter with this was in a well-worn lab notebook, with the professor underlining the formula three times. The message was clear: understanding the formula unlocks how this compound operates in the real world.

What’s Happening Chemically

The story of tetramethylammonium bromide begins with methyl groups—simple carbon and hydrogen pieces—attached to that central nitrogen. The nitrogen grabs and holds on to these groups tightly, creating a positively charged ion (cation). The bromine part brings the negative charge (anion). Pair the two, and you’ve got a salt that dissolves well in water and many organic solvents. In the lab, that’s gold: anything that slides easily into a solution becomes valuable for chemical reactions or process tweaks.

Why People Care About This Salt

Anyone who has set foot in a lab—be it in a university or an industrial plant—knows the value of simple, reliable salts. Tetramethylammonium bromide often pops up in technical settings as a phase-transfer catalyst. This helps stubborn chemicals from two different worlds (say, water and oil) mingle more freely, making reactions more efficient. The process, which used to drag on for hours, speeds up with this compound riding shotgun.

I remember seeing this firsthand in a scale-up reaction. Switching to tetramethylammonium bromide sliced hours off timelines and pushed yields up. Everyone in the room could relax a bit with less pressure to hit production targets.

Health and Safety Aren’t Just Side Notes

Salts like this one aren’t just lab curiosities. They matter for safety officers and researchers. People handle them in research, pharmaceuticals, and even electronics. Whenever you’ve got a nitrogen-heavy compound tied to a methyl group, a little caution always helps. Tetramethylammonium compounds have earned respect for their biological activity—which is a nice way of saying you never want to breathe these powders or let them soak into your hands.

Safety data shows that effects aren’t just hypothetical. Skin contact or inhaling powder can irritate or cause real harm. That’s why real-world training and personal protective equipment aren’t extras for chemists using ammonium salts; they’re essentials.

Solutions for Safer Use and Environmental Care

Plenty of places commit to strict protocols when working with quaternary ammonium compounds. At universities, regular reminders and easy access to gloves, masks, and fume hoods go a long way. Waste handling needs just as much attention. Everything goes into labeled containers and, after collection, moves to facilities set up for neutralization. This kind of process shows respect not just for workers but also for the water and soil around us.

Real-World Impact

The formula (CH3)4NBr tells a bigger story than just elements bound together. For researchers, it feels like a tool that saves time and pushes projects forward, but it also reminds us to stay sharp about health and environmental risks. Knowing what goes into these reactions, and how to handle them safely, turns complicated chemistry into something that works for science and society.

Getting to Know the Chemical

Tetramethylammonium bromide often shows up in university and industrial labs, mostly because of its use as a phase transfer catalyst. The white crystalline powder looks pretty innocent at first glance, but anyone who’s moved around baggies of powdered chemicals knows complacency causes accidents. I once grabbed the wrong bag because the label’d worn off—just a reminder labels, lids, and clear protocols protect people, products, and projects.

Why Proper Storage Matters

Some folks might treat this chemical like a bag of flour stashed on a basement shelf, but even a relatively stable salt like this brings its own hazards. Tetramethylammonium bromide pairs up with water far too easily—hygroscopic materials soak up moisture before you know it, clumping, dissolving, or turning sticky in humid air. Left unchecked, a ruined batch can end a synthesis, mess up yields, or put you far behind schedule.

Besides the ruined product, the exposure to moisture can increase the risk of handling a contaminated chemical. My own experience cleaning out an old chemical cabinet taught me: a sticky, mysterious substance inside a cracked jar rarely gets a “let’s try our luck” attitude. Most of it goes straight into the waste stream, and the cost adds up.

Practical Steps for Safe Storage

Every day, hundreds of chemists work with chemicals that behave a lot like tetramethylammonium bromide. Most store it in tightly sealed glass bottles or approved high-density polyethylene containers. Glass usually wins when purity needs to stay at its peak. The seal acts as the best barrier, blocking moisture and stray airborne contaminants. Sometimes, folks even toss a few silica gel packs in the cabinet or inside the outer storage box—especially helpful if humidity sneaks up during the summer months.

The Location Factor

It pays to think about storage location. This chemical holds up fine at room temperature if the space stays dry, cool, and out of direct sunlight. Sunlight breaks down plenty of other compounds—bad things happen to sensitive reagents on sun-drenched Windowsills. Over the years, the best results come from a cabinet away from drafts, vents, or radiators. If you store next to the sink, you’re asking for trouble; humidity and accidental splashes don’t mix well with most salts.

Odors or strong acids also stir up reactions that ruin certain quaternary ammonium salts. I’ve worked in labs where too many chemicals lived side by side. Fewer risks land on your desk when you keep strong acids, bases, and organics in separate, clearly labeled zones.

Labeling and Accountability

Simple labeling--full chemical name, concentration, date received, and source--cuts confusion and waste. In labs where people rotate through shifts, precise records build confidence. I recall a coworker’s mistake that spilled over to three departments—all because someone left an ambiguous jar on an unlabeled shelf.

Emergency Preparedness

Accidents happen, and that’s where training kicks in. Anyone handling tetramethylammonium bromide should know where to find the Material Safety Data Sheet, spill kits, gloves, goggles, and what steps follow a drop or accidental contact. Investing a little effort upfront saves time, money, and keeps people safe.

Understanding Purity in Everyday Research

Ask any chemist about Tetramethylammonium Bromide, and purity becomes a central part of the conversation. On paper, the options usually show up as 98%, 99%, or 99.5% pure. In academic labs, folks often pick up bottles marked “ACS reagent grade” or “analytical grade,” with a label that promises 99% or better. Over the years I’ve noticed that the difference between 98% and 99% sometimes spells the difference between a messy experiment and clean, predictable results.

For researchers working with organic synthesis or materials science, impurities—even those lurking below one percent—can mess with catalysts, react with solvents, or show up in final products. This really shows its teeth when using sensitive techniques, like NMR spectroscopy or electrochemistry. One time, a supposed impurity in a low-grade salt kicked off signals in an NMR spectrum that sent us chasing ghosts for weeks. Ever since, I’ve been picky about bottle labels and supplier reputations.

Grades on the Market

In chemical catalogs, Tetramethylammonium Bromide appears under a few grades:

- Analytical Reagent (AR) or ACS Grade: This level gives 99% or 99.5% purity, common in research and education.

- Laboratory or Technical Grade: Typically around 98% purity, often cheaper, with a warning that traces of water or other salts may tag along.

- Ultra-Pure or HPLC Grade: Rare for this specific salt, but sometimes found at 99.9% or higher, usually for chromatographic or electronic applications.

Over the years, suppliers like Sigma-Aldrich, Merck, Alfa Aesar, and TCI all offer something in the 98–99.5% window. The small jump, from lab grade to analytical, means a lot for projects where just a whiff of the wrong ion trips up an entire set of tests or production runs. Purity isn’t just a nice-to-have—sometimes it’s the difference that makes science reliable and scalable.

Purity, Price, and Real-World Consequences

Costs run up as purity rises. In a small student lab, paying a premium for 99.9% doesn't make sense unless the protocol demands it. For industrial use, investing in higher grades helps dodge much bigger losses down the line—from failed quality checks to contaminated lots.

I remember a case from a textile company trying to switch over to a digital dye process. They cut corners on chemicals, and the “cheap” 98% Tetramethylammonium Bromide left micro-impurities that bled through on color panels, costing them far more than that saved margin. In situations like this, the up-front expense of a better grade finally makes sense in hindsight.

How to Handle the Purity Question

For researchers and buyers, check the certificate of analysis for each shipment. Ask suppliers to detail their purification steps and batch history. Simple tricks like keeping containers airtight and dry go a long way to preserve stated purity, especially since hydroscopic salts grab moisture from the air if left open. In my own work, even the best bottle loses a half percent quality if left out for a few hours during humid days.

In short, Tetramethylammonium Bromide usually comes in at 98%, 99%, or 99.5% purity. Picking the right grade saves headaches, resources, and, sometimes, entire projects. If chemistry is about getting consistent, useful results, then purity isn’t something to take lightly.