Tetrachloroethylene: History, Science, and Current Impact

Historical Development

Through industrial history, tetrachloroethylene has marked its presence as a key player in the chemical sector. When the textile and dry-cleaning boom kicked into gear in the early 20th century, this compound landed at the center of solvent technology. It started showing up as a safer substitute for more flammable fluids. Factories in the U.S. and Europe began churning it out in bulk, using a process that transformed simple hydrocarbons with chlorine gas. Early researchers didn’t realize the full scope of its impact—both good and bad. From trichloroethene-based processes to direct chlorination, companies constantly refined their methods to squeeze out higher yields and purer product, responding to rising consumer demand and tighter quality standards as the decades rolled by.

Product Overview

Tetrachloroethylene, known all over as perchloroethylene or “perc,” punches well above its weight as a commercial solvent. Its widespread use in dry cleaning made it a household name among launderers and industrial workers alike. Today, it turns up not just in laundry shops, but in paint removers, degreasing fluids, and even some typewriter correction products. I’ve found that no matter the label on the drum, folks in manufacturing circles speak about it with the same respect, often recounting how small changes in product sources or grades can steer processes off course if the specs shift by just a fraction.

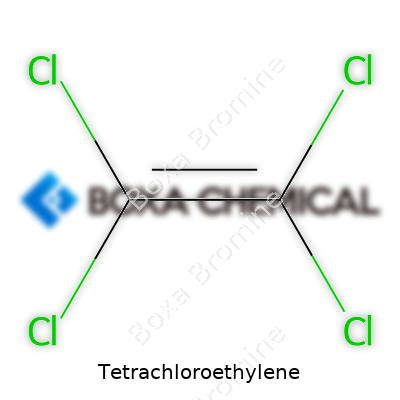

Physical & Chemical Properties

This compound shows up as a clear, colorless liquid with a sharp, sweet odor that most seasoned workers can spot from across the shop floor. Boiling at about 121°C and freezing near –22°C, it doesn’t mix with water, but dissolves grease and oil without fuss. In terms of chemistry, it comes down to the sturdy presence of four chlorine atoms attached to an ethylene backbone, making for a dense, stable molecule, around 1.62 grams per cubic centimeter. Its vapor is heavier than air, which means it hugs the ground in poorly ventilated spaces, something I learned from an old-timer who pointed out the danger in out-of-the-way basement shops.

Technical Specifications & Labeling

Regulators and manufacturers tag tetrachloroethylene with strict guidelines. Labels highlight flammability—or the lack of it—plus instructions for safe storage at room temperature, away from open flames or strong oxidizers. Standard technical sheets spell out concentrations, allowable impurity levels, and recommended personal protective equipment. I’ve read through more than a few of these, and it’s clear that small variations in purity can separate high-grade, electronics-ready solvents from those geared for heavy-duty degreasing. Requirements for workplace safety sheets stack up quickly, a sign of how seriously industrial culture takes transparency around hazardous chemicals.

Preparation Method

In the past, producers used acetylene or ethylene as feedstock, mixing in plenty of chlorine, and running the reaction hot enough to break old bonds and forge new carbon-chlorine links. Modern methods usually start with trichloroethylene, running another batch of chlorine through to round out the quartet, then distilling the product under strictly controlled conditions. Efficiency has gone up as reaction byproducts get less wasteful, especially now that environmental rules have forced plants to wring every last drop out of batches and scrub exhaust streams before sending them outdoors.

Chemical Reactions & Modifications

Tetrachloroethylene stands out for its chemical stubbornness; it resists most attempts at direct alteration under ordinary conditions. Under strong UV light or with vigorous heating, it can break down, spinning off phosgene, hydrogen chloride, or trichloroacetic acid—none of which you want wafting around an unprepared workspace. Mix it with certain metals or strong bases in water, and the breakdown products quickly pile up, which changes the game in environmental cleanup, where breaking down spilled solvent brings its own concerns. In labs, chemists have found ways to nudge the molecule toward useful derivatives, but always with heavy oversight and preparation.

Synonyms & Product Names

No matter where you look, the chemical answer sheet lists names like "perc," "tetrachloroethylene," and "perchloroethylene." Legal documents often refer to it as UN1897 or by its IUPAC name, although on the ground, industry catalogs just call it "perc" or solvent 113. I’ve seen product codes change from one supplier to another, so smart end-users always double-check Safety Data Sheets for confirmation before pouring from a new barrel. This kind of vigilance gets baked into shop routines over the years, with experienced hands teaching the young ones to pay close attention to the fine print.

Safety & Operational Standards

Long hours spent with this solvent have driven home the truth that safety doesn’t happen by accident. The rules on tetrachloroethylene reflect its risks: air monitoring, splash protection, tight ventilation, and prompt spill control. Anyone who has spent time in a chemical plant or machine shop learns to respect the limits set by OSHA and their international counterparts. Guidelines cap airborne concentrations at a few parts per million, because exposure above these levels leads to headaches, dizziness, or worse. Personal experience says even a whiff out of range can provoke a raw throat and an unpleasant sense of just how insidious industrial chemicals can be.

Application Area

In practice, tetrachloroethylene keeps showing up where other solvents struggle. Its mainstay remains fabric dry cleaning, where its power to lift stains and preserve fibers led to industry-wide adoption. Machine shops rely on it to strip engines and precision parts down to clean metal, while automotive and electronics manufacturers prize its role in degreasing. At home, it shows up less often, but anyone who’s picked up dry-clean-only clothing or paint remover has probably crossed paths with perc. Even laboratories favor it sometimes for extracting organic compounds or separating mixtures. Over decades, regulations have squeezed out the most hazardous uses, steering it away from consumer products.

Research & Development

Research around tetrachloroethylene shifts focus as public health findings evolve. Industry scientists and university researchers have worked to limit worker and environmental exposure, exploring closed-loop systems, better masks, and new sensor technologies for air monitoring. Some teams hunt for greener alternatives, running tests on hydrocarbon blends, silicon-based solvents, or even supercritical CO2. Yet, most alternatives come with their own strings attached, often lacking the cleaning punch or bringing new safety questions. It’s clear from years spent in research labs that total replacement would reshape not just chemistry textbooks but entire industries.

Toxicity Research

Evidence paints a clear picture: tetrachloroethylene carries real health risks if mishandled. Animal studies link long-term exposure to liver and kidney problems, with potential ties to cancer. A number of high-profile lawsuits in the U.S. and Europe connect workplace exposure or contaminated drinking water to clusters of health complaints. Regulators require testing for vapor concentrations in air and strict record keeping for workplace exposure. Doctors watch for neurological symptoms in affected workers, treating headaches or impaired coordination as a red flag. Even with declining usage, the legacy of contaminated soils and aquifers keeps public health departments on alert wherever old dry-cleaning shops once stood.

Future Prospects

Looking ahead, fewer new installations embrace tetrachloroethylene as a first choice. Companies design out solo-solvent cleaning wherever possible, writing safety and sustainability into product specs from day one. At the same time, legacy infrastructure locks it into the supply chain, making rapid replacement costly and tricky. Cleaning firms and manufacturers invest in on-site recycling tech, keeping emissions down while eking out a few more years of use. Civic groups push regulators to raise the bar for environmental cleanup, and firms face growing pressure to shift to less toxic, biodegradable options. The whole picture points toward a slow but steady pivot, shaped by stricter health regulations and a new generation of chemical engineers eager to leave a cleaner legacy.

A Common Sight in Dry Cleaning Shops

Most folks know tetrachloroethylene as the strong-smelling stuff used to get stains out of clothes at the dry cleaner’s. Many people call it “perc.” Over the past forty years, I've dropped off everything from work shirts to winter coats, and each time I pick up clean clothes, I still notice that faint, chemical smell left behind. This solvent does the job that water and regular soap just can’t do with some fabrics and stubborn stains. It punches through grease, oils, and grime that would ruin delicate fibers or leave marks behind.

Industry Can't Quit Perc Yet

The story doesn't end with dry cleaning. Tetrachloroethylene serves a purpose in other workplaces. Factories rely on it to degrease metal parts. Try fixing a car, and you’ll see how tough oil and residue can be to budge from gears and engine pieces. Perc just cuts through the mess. Textile mills also use it in fabric finishing, and chemical production plants keep it in the tool kit for making certain refrigerants and fluorinated compounds.

The chemical works because it evaporates fast, pulls out oil without leaving much residue, and doesn’t eat away at most materials. It even shows up in the making of paint strippers, glues, and some spot removers you’d find under the kitchen sink. Dry cleaners like it because it keeps delicate items (including suits and wedding dresses) from shrinking or changing color, unlike regular laundry.

Risks in the Air and Ground

Using tetrachloroethylene brings up bigger questions about health and the environment. I remember reading headlines about workers and neighbors getting sick near cleaning shops. The Centers for Disease Control and Prevention and the Environmental Protection Agency have flagged “perc” as a possible cancer risk. It can also irritate the skin, eyes, and lungs, and build up in the body with enough exposure. Spills and leaks seep into soil and reach groundwater if shops or factories don't follow safety rules. Years ago, the ground beneath a row of dry cleaners in my city needed massive clean-up after decades of dumping waste down the drain.

Many countries have started to push for safer handling rules and have forced dry cleaners to adopt better equipment or face closure. In some cities, landlords can’t lease retail space to new dry-cleaning businesses that would use tetrachloroethylene. From California to Denmark, governments target the phase-out of perc for public health.

Cleaner Alternatives and the Real Challenge

Folks searching for a clean shirt shouldn’t have to worry about hidden risks. New options include liquid carbon dioxide cleaning and “wet cleaning” technology that uses water in a gentle cycle with special detergents. These methods promise less impact on people and nature. Some shops already switched, but the cost and access to the right machines keep others locked into using perc. Dry cleaners operating in older neighborhoods or on a tight budget find it tough to let go of the chemical their businesses rely on.

If we want fewer chemicals in our air and water, we need bigger conversations. Real help could come with grants or easier loans for small businesses that want to move away from dangerous cleaners. Public schools and city governments can lead by choosing non-toxic companies for uniforms and linens. Everyone with a pile of dirty laundry can ask where their cleaner stands on the issue, pushing demand toward safer choices.

Keeping a Watchful Eye

Tetrachloroethylene has given companies efficient cleaning power for generations, but the bill keeps coming due. It makes sense to look for smarter ways to keep clothes fresh and communities safe at the same time. Less pollution and better health outweigh the short-term savings that come from clinging to old chemicals.

Tetrachloroethylene and Where It Shows Up

Many folks know tetrachloroethylene as the main cleaning agent behind most dry-cleaned clothes. Some call it “perc.” It’s in commercial spot removers, degreasers, and can even show up in home products if you’re not careful. Growing up, I’d sometimes catch a whiff of sharp, almost sweet odor walking past a dry cleaner. I never thought much of it until I started hearing about health risks tied to the stuff.

Why People Worry

Experts have shared strong links between tetrachloroethylene exposure and serious health issues. Breathing air laced with high concentrations can cause dizziness, headaches, and in worse cases, damage nerves or affect memory. My neighbor once worked at a plant using perc daily—years later, he started struggling with tremors and focus. Doctors traced it back to long-term exposure.

Several studies, including findings from both the U.S. Environmental Protection Agency and International Agency for Research on Cancer, have labeled tetrachloroethylene a “probable human carcinogen.” Workers dealing with it every day carry the biggest risk. Research points to possible ties to bladder cancer and certain blood disorders, too. Even people living near dry cleaners report higher risks for breathing problems.

What About Ordinary Exposure?

Folks picking up clean shirts from a shop probably don’t hang around high enough concentrations to worry about cancer. Still, poorly ventilated shops can make fumes hang in the air, seeping into apartments above dry cleaners. That means residents sometimes feel the impact along with the staff, whether they realize it or not.

Trying to Fix the Problem

Regulations on tetrachloroethylene have grown stricter over the years for a reason. There are now strong controls around worker safety—better ventilation, more personal protective equipment, and regular testing for leaks. Some cleaners now use “wet cleaning” systems or alternative solvents, aiming to reduce health issues where possible. California has even passed laws to phase out perc altogether in its dry cleaning industry.

People can take their own steps at home, too. Airing out newly dry-cleaned clothes in a garage or well-ventilated space lowers indoor air exposure. Choosing cleaners that offer “green” or alternative processes limits your own contact with risky chemicals.

What Industry and Communities Can Do Now

It helps to push for clear labeling and transparency around any chemical dangers, not just inside industry but in consumer spaces. Early in my working life, clear information on chemicals and better training would have helped the crew avoid a few close calls. Community groups near dry cleaning hubs need a voice in zoning decisions and building codes. Stronger communication between local agencies and business owners also goes a long way to stop contamination of groundwater and indoor air.

Tetrachloroethylene shows why chasing convenience can sometimes mean risking health. In my own family, we started spread drying clothes at home and picking less chemical-heavy cleaning when possible. Building this awareness in communities—supported by respected studies, worker experiences, and real-world data—feels like the best way forward. Knowledge protects more than just those on the front line; it keeps neighborhoods safer too.

Why Care About Tetrachloroethylene?

Tetrachloroethylene, also called perchloroethylene or “perc,” pops up often in dry cleaning and metal degreasing shops. What concerns me—and what should concern anyone who deals with chemicals—is that this solvent hits hard when safety falls short. The stuff evaporates quickly and lingers in the air, and even quick whiffs can leave a headache or dizziness. Prolonged exposure, especially in places with bad ventilation, leads to even worse health problems, like nervous system trouble and a higher risk of certain cancers, according to research cited by the National Institute for Occupational Safety and Health.

Where Things Go Wrong

Walking into a cluttered storage area with drums stacked haphazardly and ventilation as an afterthought, I see trouble coming from a mile away. Spills stink up the air, and open drums mean toxic vapors float around unchecked. Even a splash onto skin burns and causes irritation right away. The real danger, though, comes from cutting corners just to save time—or thinking minor leaks don’t matter. That’s where workplace injuries and chronic health issues start stacking up.

Good Storage is Good Common Sense

Straight from my old factory days, safe storage starts long before the chemical hits the shelf. Use heavy-duty containers, usually steel drums that don’t react with perc. Go for sealed lids, never dented or makeshift covers, to lock in fumes. Set containers on spill-containment pallets—never right on the ground—so leaks don’t seep into the floor or water supply.

I always remind newer staff that perc doesn’t mix well with sunlight or heat, so stick to a cool, covered storage room. Fire risks usually get overlooked, but tetrachloroethylene vapors can catch with a strong enough heat source. That’s why storage spaces should shun open flames, sparks, welding equipment, or any smoking. Store it away from food, drink, or anything edible. Lax storage rules turn into lawsuits and health scares way too quickly.

Handling Perc Without Drama

Get the right gear: gloves, splash goggles, and chemical-resistant aprons keep things safe. Respirators come out when levels creep up in the air, which sometimes happens on loading days or if the exhaust fans choke up. Ventilated rooms do more than paperwork or safety slogans ever will. A good exhaust fan above the mixing table lets me breathe easy, and less vapor in the air means fewer complaints about headaches or dizziness.

Pour only what’s needed. I learned early that rushing and overfilling means more spills—and mopping up perc makes for a lousy afternoon. Drums should always be kept closed after measuring or transferring. Small details, like keeping transfer pumps clean and checking hoses for wear, go a long way for safety. Clean up any spill fast with a ready spill kit, as losing precious minutes makes a small incident grow into something more expensive to fix.

Keeping Track and Training

No safety program works without solid recordkeeping. Labels should stay clear and up-to-date. Safety data sheets ought to be within reach, not buried in a drawer. Even old-timers need refreshers on new rules, and younger workers might not realize the long-term risks if training stops at orientation day. I’ve seen fewer accidents in shops that hold short safety meetings and run through the actual steps, not just policies printed out from HR. OSHA rules demand real compliance—a smart shop adds real life examples to bring the hazards, and the solutions, home.

Better Habits, Safer Shops

Every accident I’ve witnessed with tetrachloroethylene boiled down to ignoring basic safeguards. Being careful up front, with the right containers, storage routines, and personal protection, saves hassle and health later. Keep it simple: respect the chemical, trust the process, and watch out for each other. No one ever wins by cutting corners with hazardous solvents.

A Closer Look at an Everyday Solvent

Tetrachloroethylene pops up in places people don’t always expect—dry-cleaning shops, home garages, auto repair businesses, even art studios. Spot removal, degreasing, and chemical manufacturing rely on this solvent’s power. The story rarely gets told about how quickly things go sideways when safety slips, and that's where honest conversation can save headaches, or worse.

Eyes and Lungs: The Frontline in Exposure

I once stepped into a dry cleaner’s storage closet and the sharp odor hit fast—felt like breathing in harsh pool chemicals. That sting isn’t just unpleasant; it’s a warning. Short spells in rooms with no ventilation can lead to headaches, dizziness, or bad coughing. Over the long haul, health risks pile up. Studies have documented liver and kidney trouble in people working around tetrachloroethylene without protective routines. The International Agency for Research on Cancer labels it “probably carcinogenic”—so no amount feels harmless.

Open Windows Aren’t Enough

I’ve watched well-meaning folks prop open a door or window, thinking the worst part blows away fast. That’s not enough. Tetrachloroethylene vapors build up, and being heavier than air, they settle low. Fans positioned to push air out, not just move it around, actually help. Laboratories and industrial spaces go a step further by using local exhaust ventilation and air monitoring. Home-use needs caution too—running a machine with this solvent inside a house can linger for days.

Your Skin Isn’t a Barrier

Spills happen quickly—once I ended up with a splash on my jeans while helping a friend clean tools. I thought nothing of it, but tingling set in and I had to wash up. Wearing chemical-resistant gloves and aprons should be standard. Plenty of folks figure latex or thin grocery bags work in a pinch, but those can melt or let vapor seep through. Nitrile or neoprene gear stands up best. And clothes splashed even a little should be changed as soon as possible. The skin absorbs more than people expect, especially through cuts or scrapes.

Fire Safety and Safe Storage

Tetrachloroethylene won’t catch fire like gasoline, but it can break down in high heat, pouring out toxic fumes. I recall a case in a machine shop where leftover solvent near welding sparks meant emergency room trips. Metal containers with tight seals matter. Keeping barrels or bottles away from heaters and out of direct sunlight preserves everyone’s safety. Clear labeling helps anyone—seasoned workers, weekend hobbyists, or first-time users—know what they’re handling and what not to mix with it. Water or certain metals can trigger dangerous reactions, so reading the label each time stays important.

Don’t Rely on “Just Being Careful”

Checking up on local regulations adds real protection. Many cities require businesses to keep spill kits on hand, and some ban home use altogether. If spills happen, absorbent materials—not towels or rags used in kitchens—keep the spread in check. Disposal matters, too. I’ve seen waste poured down drains, not realizing that sewage plants can't handle those chemicals and the pollution spreads to rivers and groundwater. Registered hazardous waste pick-up services exist for a reason. It doesn’t just shield the environment; it keeps neighbors and pets safe, too.

Building Safer Habits

No product comes with zero risk, but tetrachloroethylene stands out for the way it forces everyone to think ahead. Protective gear, fresh air, and solid habits slow down accidents even when days get busy. Setting up direct training, or even a simple conversation in the shop, does more than posters or warning labels. People remember stories, and experience carries weight—if you’ve seen how fast a “small accident” becomes a real crisis, you never want to see it again.

What is Tetrachloroethylene?

Tetrachloroethylene, known as perc in the dry cleaning world, has been around for decades. It dissolves grease and lifts stains off clothes like nothing else. Dry cleaners, metal degreasers, and some consumer products use it because it works quickly and doesn’t leave behind a strong odor. But ease and speed come at a price.

Environmental Impact: What We See and Don’t See

Walking past a dry cleaner, a faint chemical smell sometimes lingers. That’s perc, and if it seeps into soil or groundwater, there’s trouble. This solvent doesn’t stick to dirt or dissolve in water much, so it stays on the move underground. Once there, it can spread far from the point of release and stay for years. Perc as a groundwater contaminant shows up in water wells and, over time, enters drinking water supplies and irrigation systems.

People living near facilities using perc sometimes report headaches and skin irritation. The US Environmental Protection Agency calls tetrachloroethylene a likely human carcinogen. Long-term exposure, even at low doses, links to nervous system effects and liver and kidney damage. States like California have tracked higher rates of certain cancers among people living near old dry cleaners and storage sites.

Wildlife and Waterways

Perc leaves a mark on more than just people. Fish and aquatic insects exposed to contaminated water build up the chemical in their tissue. Even low levels cause trouble, slowing growth and disrupting reproduction. Animals further up the food chain eat contaminated fish, letting the pollution pile up through the ecosystem. Urban spills and leaks often wash into storm drains, which lead to local streams, rivers, or lakes, amplifying the problem.

Repairing the Damage

Cleanup isn’t simple. Removing perc from groundwater or soil requires specialized technology, and often costs millions for a single site. Pumping and treating water, or baking soil in place to break down the chemicals, takes time and expertise. Contaminated sites linger for years. Real estate can lose value because of it. Countless neighborhoods classify empty lots as brownfields—untouchable, stuck with a toxic legacy from earlier decades.

What Are Better Options?

Some dry cleaners have switched to wet cleaning or CO2-based solvents, which don’t threaten water or air the same way. Both methods clean clothes just as well and use less energy. Supporting businesses that use safer methods gives consumers a direct way to help. Regulations continue to push cleaners and factories to find safer alternatives. In some cities, grants or tax breaks encourage shops to upgrade their equipment or change their process altogether. Yet older operations often struggle to afford these costs without outside help.

Supporting Change

It’s easy to assume dangerous chemicals belong only in rare corners of industry, but the real story lies close to home. Everyday habits push the problem further. Reading local water reports, supporting green cleaners, and asking how your own clothes get cleaned make a difference. Small changes add up. Awareness and consumer demand nudge businesses toward safer options and, over time, shrink the reach of hazardous chemicals like tetrachloroethylene.