Phenylbromide: Looking Deeper into Its Story and Importance

Historical Development

Chemistry labs during the late 19th and early 20th centuries thrived on simple, robust reagents that allowed chemists to tinker with the molecular world. Phenylbromide, also called bromobenzene, kept popping up as researchers looked for easy ways to add bromine into organic frameworks. Early papers detail its preparation by direct bromination of benzene, often with iron filings as a catalyst, filling glass retorts in dimly lit workshops. For a long time, this chemical mostly acted as a tool—a means to an end. The shift toward larger-scale chemical manufacturing during the World Wars, paired with advances in organic synthesis, pushed phenylbromide into broader industrial circulation. Its legacy runs through dye production, pharmaceuticals, and as a benchmark in the study of aromatic substitution reactions.

Product Overview

Phenylbromide looks like a colorless to pale yellow liquid. It boils at 156°C and offers a faint, sweet odor. It's recognizable by chemists for its role as an intermediate, practically a "building block" for other carbon-bromine compounds. The molecular formula reads C6H5Br, there isn't much else but a simple six-membered benzene ring with a bromine atom attached. Market suppliers bottle it in dark glass to slow oxidation or decomposition. The product sees most of its journeys heading to the fine chemicals sector, with companies that value its reliability and compatibility in multi-step synthesis.

Physical & Chemical Properties

Liquid at room temperature, phenylbromide registers a density notch higher than water at about 1.5 g/cm³. It doesn't mix with water, thanks to its hydrophobic benzene core, but dissolves cleanly in ether, ethanol, and other organic solvents. The bromine atom anchored to the ring offers unique chemistry—more reactive than benzene itself, but more stable than, say, alkyl bromides. On exposure to light or air, it doesn't decompose quickly. Careless storage still brings risk; heat can trigger hazardous fumes, and mixing with strong bases or metals demands attention to prevent accidents.

Technical Specifications & Labeling

Commercial phenylbromide carries an assay of at least 99%, with water content below 0.1%. Purity means a smoother reaction downstream, so manufacturers emphasize the absence of isomers and halogenated byproducts. Labels feature standard chemical identifiers, hazard pictograms for irritant/inhalation risk, and the familiar EC and UN numbers. Shipping requires specific documentation to comply with both local and international rules. Certificates of analysis often come with batches destined for regulated markets, especially pharmaceutical production, where trace impurities raise red flags during quality audits.

Preparation Method

Industrial synthesis mostly sticks to classical routes. Brominating benzene with elemental bromine, catalyzed by iron or ferric bromide, remains the workhorse. The process involves slow addition and careful temperature control to avoid polybromination. Strip away unreacted bromine and distil off phenylbromide under reduced pressure if quality matters. Smaller labs might tweak conditions, perhaps using N-bromosuccinimide (NBS) for mildness, but the principle stays similar. Crude product often gets washed with base to pull away acids and leftover catalysts before drying and purification.

Chemical Reactions & Modifications

Phenylbromide lets synthetic chemists swap out its bromine for a wide range of functional groups. The C–Br bond opens opportunities through nucleophilic aromatic substitution, especially when electron-withdrawing groups flag the ring. More often these days, researchers tap palladium-catalyzed cross-coupling: Suzuki, Heck, and Stille reactions leap to mind. These methods bolt on carbon chains or build up complex pharmaceutical frameworks from simple starting blocks like phenylbromide. The molecule also fragments cleanly under certain reduction conditions, breaking back to benzene if desired. Its reactivity drives innovation across materials, agrochemicals, and drug development.

Synonyms & Product Names

Across catalogues, phenylbromide answers to several titles: bromobenzene, monobromobenzene, and UN No. 2514. European suppliers often use the EINECS number 203-625-9. Some older chemistry texts cite 1-bromobenzene to avoid confusion with other halogenated benzenes. No matter the name, chemical structure keeps it rooted in the aromatic bromide category, where its companions—chlorobenzene and iodobenzene—fill similar roles.

Safety & Operational Standards

No one should underestimate the handling risks tied to phenylbromide. Vapors can catch fire when the liquid approaches its flashpoint at about 51°C. Inhalation brings headaches and dizziness, skin or eye contact stings and reddens, while accidental ingestion calls for immediate medical attention. Standard practice involves working under fume hoods, using gloves and goggles, and storing chemical stocks away from heat or oxidizers. Safety Data Sheets (SDS) spell out proper first-aid, spill protocols, and compatible fire extinguishers. Larger manufacturers build in controls—ventilation, spill retention, and regular air monitoring—so employees don't pay the price for a preventable exposure or accident.

Application Area

Labs across pharmaceuticals and agrochemicals lean heavily on phenylbromide for coupling reactions and synthesizing active intermediates. In material science, it's a stepping stone for pushing performance of specialty polymers and liquid crystals. Dye and pigment makers pull it off the shelf to create vibrantly colored aromatic compounds. In smaller volumes, academic researchers explore new reaction pathways and mechanistic studies using phenylbromide precisely because of its responsiveness in classic reactions. It doesn't carry the same complexity as some newer molecules but delivers consistency students and professionals appreciate.

Research & Development

Phenylbromide still finds its way into the heart of R&D programs worldwide. Scientists keep searching for cross-coupling reactions that cut waste and energy use. Green chemistry efforts aim to swap harsh solvents and toxic reagents for milder, more recyclable alternatives. Every so often, a paper appears on using sunlight or non-metal catalysts to drive traditional reactions involving phenylbromide, promising a lower environmental burden. The molecule attracts attention in computational studies, too—bench chemists validate predictive models or explore electronic effects by observing its behavior in reaction networks that mimic those found in natural products or pharmaceuticals.

Toxicity Research

Concerns over phenylbromide's impact on health and environment come with good reason. Animal studies say inhalation or prolonged skin contact affects the nervous system. Regulatory agencies flagged it for moderate environmental persistence, noting potential toxicity to aquatic life. Chronic exposure—unlikely for most casual handlers but on the radar in large production settings—raises risks of liver or kidney impacts. Mitigation strategies involve closed processes and rigorous personal protective gear. Ongoing toxicology initiatives fill in gaps, particularly with low-level, chronic exposure scenarios relevant for workers in specialty chemical manufacture.

Future Prospects

As the world calls for smarter, less hazardous chemicals, phenylbromide will face fresh challenges and chances for reinvention. Regulatory tightening might push for safer substitutes in sensitive end products like children's toys or food contact materials. At the same time, advancements in catalysis and green chemistry may unlock ways to use phenylbromide more efficiently and with less waste, so it remains relevant to both traditional synthesis and emerging technologies. Intellectual curiosity will keep the door open for exploring derivatives or modifications that better suit tomorrow’s molecular engineering challenges. Its established track record as a reliable starting material means the story of phenylbromide isn’t close to finished yet.

A Closer Look at Phenylbromide in Everyday Science

Phenylbromide doesn’t turn heads on a street corner, but lab folks and industry know its value. On paper, it’s often called bromobenzene. It looks simple–a benzene ring bonded to one bromine atom–but this liquid has quite a few uses.

Getting the Chemistry Straight

The first time I bumped into phenylbromide was in an organic chemistry lab. It’s a clear, slightly sweet-smelling liquid, but you don’t want to breathe in too much. In that setting, we used it as a building block for making other molecules, which is really where phenylbromide pulls its weight. This chemical slips right into all kinds of synthetic routes. Pharmaceutical chemists lean on it because the bromine atom acts as a great leaving group, which basically means it can pop off and make room for other atoms during a reaction. You want to build a more complex structure for a drug candidate? Pull out phenylbromide, and you’re halfway there.

Industrial Stories: Dyes and Flame Retardants

Beyond labs, phenylbromide makes an appearance in manufacture. Dye producers use it to create the sort of color-fast, rich pigments you spot on clothing or printed materials. The bromine in its structure brings stronger, more reliable chemical reactions, which means better control over the final color product. Plastics and textiles industries also turn to phenylbromide to help whip up flame retardants. Fire safety takes more than sprinkling magic dust—instead, producers tweak molecules at a base level. By inserting bromine-containing structures from phenylbromide, lots of everyday objects, from phone casings to seat covers, get an extra layer of fire resistance.

From Research to Problem Solving

A deep dive into scientific literature shows phenylbromide cropping up in new chemistry approaches. Chemists researching greener or more efficient reactions often use it as a test case or starting point. If a new catalyst can do something interesting with phenylbromide, there’s a good shot it’ll work with other similar molecules, too. That’s because the molecule’s benzene ring is a predictable playground for experiments, making it a good ‘benchmark’ for judging the value of new ideas.

Health and Environmental Footprint

Every industrial chemical raises questions about safety. Phenylbromide can irritate your skin, eyes, and lungs. Long-term or high-level exposure has been linked to chronic issues. In my own experience, even careful chemists make mistakes—an unnoticed spill, a whiff in the air. Proper ventilation, personal protective equipment, and clear safety protocols sound obvious, yet they drift from memory in a rush. Companies and labs have to invest not only in protective gear but also in thoughtful training and regular safety reminders. Taking short cuts with phenylbromide (or any volatile chemical) leaves real people with health risks.

Thinking Toward the Future

Workers and researchers want tools that work well and don’t come at a hidden cost. The push for safer alternatives tracks alongside changes in regulation: less hazardous substitutes, better waste treatment, and technology that captures and reuses solvents. I’ve seen some labs switch to newer catalytic systems that minimize the need for brominated solvents altogether. These efforts don’t just clean up waste streams—they chip away at long-term health and environmental concerns.

Why This Chemical Matters

Phenylbromide isn’t just an obscure lab staple. It shapes how we develop drugs, build safer products, and test new chemical ideas. Responsible handling and continued innovation around its use send a strong signal that even behind-the-scenes chemicals deserve full attention—not just for efficiency, but for health, sustainability, and progress in science.

Everyday Exposure and Real Concerns

Phenylbromide pops up in the lab, a clear liquid with a heavy sort of smell. Anyone who has spent time around chemical syntheses or research projects recognizes it as more than just another reagent. The stuff doesn’t ask permission to irritate your skin or eyes. You splash some, and you feel it. I remember a colleague splattering a bit across the bench: the eye-watering fumes spread quickly, far stronger than you’d expect from such a simple-looking bottle. Stories like that teach you to keep the fume hood sash low and gloves on at all times.

What Science Tells Us

Trusting your instincts pays off, but actual data matters just as much. Phenylbromide (also called bromobenzene) comes with a material safety data sheet that pulls no punches: inhalation can irritate your airways, and skin absorption brings more discomfort than most people bargain for during a workday. Chronic contact doesn’t disappear quietly either. Animal studies suggest long-term effects involve the liver and even nervous system problems with heavy or careless exposures.

These results aren’t just science for science's sake. In 2020, I reviewed a set of toxicity studies for a safety briefing. Researchers found that repeated inhalation of phenylbromide led to changes in blood chemistry—liver enzymes rose and some animals got sluggish. Regulatory agencies, including the European Chemicals Agency and OSHA, point to acute and chronic risks for folks working without proper controls.

Waste Not, Want Safety

Disposing of phenylbromide doesn’t fit with pouring it down a drain or tossing the bottle in trash. It builds up in water, sticking around a lot longer than you’d hope. A few years ago, labs at a university where I worked started tracking solvent waste more closely. The audit found small leaks from broken containers and uncovered bottles. The fix? Investing in tight-sealing cans and clearer training—which worked. Small steps like that stopped a lot of careless exposure.

Vapors and spillage don’t send an alert before causing trouble. Some gloves work better than others—nitrile does a decent job for short periods, but the chemical slips through latex. Respirators have their role if hoods break or when working in tight spots. Laboratories relying on good ventilation cut risks way down. These practicalities make handling phenylbromide safer, and policies pushing for smart storage and regular safety drills make the biggest difference.

What We Can Do Moving Forward

No one walks into a lab wanting trouble from a bottle of phenylbromide. Training newcomers on chemical risks—the real stories, not just dry safety sheets—grabs attention. Labs that keep their chemical inventories current and audit their storage work smarter, not just harder. Swapping phenylbromide for safer alternatives solves the issue at its root, though substitutes don’t always fit every reaction or process.

Occupational health gets a boost from listening to folks on the ground. Input from people handling the chemical shapes policies that really work. Air monitoring, better personal protective equipment, and simple habits—like never working alone with hazardous chemicals—save more than just frustration.

The science is plain: phenylbromide isn’t something to treat lightly. Awareness plus action keeps risks in check and lets researchers get on with their work.

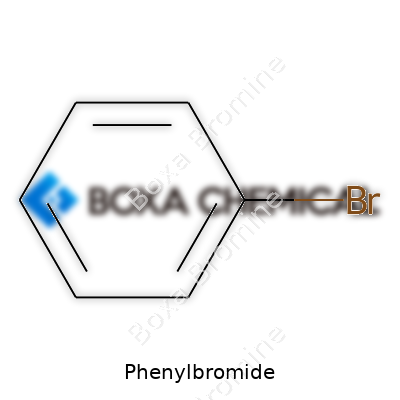

Unlocking the Formula: C6H5Br

Phenylbromide, often labeled as bromobenzene by chemists, carries a simple yet telling formula: C6H5Br. Spotting that “Br” tacked onto the familiar benzene ring signals more than just a swap on the periodic table. In research labs, classrooms, and manufacturing plants, this molecule plays a bigger role than many would guess from its modest name.

Aroma of the Lab—And a Wake-Up Call

Anyone who walked into an organic chemistry lab remembers the first whiff of phenylbromide. There’s something unforgettable and slightly sweet about its scent. Chemists immediately realize they’ve left safety goggles behind. I recall making my first batch of phenylbromide for a project. It’s a classic: take benzene, invite a bit of bromine, throw in an iron catalyst, and out comes C6H5Br. It feels like magic, watching those color changes and knowing exactly what’s coming together at the molecular level. Yet, that creation is a reminder: everything in the flask demands respect and responsibility.

Not Just for Textbooks—A Building Block in Industry

Bromobenzene stands as more than a lab demo. Its true strength comes out on the factory floor, forming stepping-stones for bigger things. This molecule lays the groundwork for pharmaceuticals—think painkillers and antihistamines—even if the bottle never mentions it by name. Synthetic intermediates don’t make the headlines, but life-saving drugs wouldn’t exist without them. C6H5Br also shapes dyes and pesticides. A lot of color in our world starts with chemistry you can’t see.

Navigating Safety and Environmental Concerns

Handling phenylbromide calls for respect. Its volatility, flammability, and moderate toxicity put emphasis on safety gear and ventilation. Science has a long record of learning the hard way—stories of headaches, skin troubles, and misjudged risks pop up in every department. News on chemical spills and improper storage can sometimes read like history repeating. To fix the pattern, labs and manufacturers now push for better training, stricter safety standards, and green chemistry. Less hazardous alternatives are in development for a reason, and real-world experience teaches that safety reminders should never fade.

Solutions Spark Change

Every generation of chemists faces the push to do better, both for the science and for society. The replacement of older, more dangerous chemicals keeps researchers looking for new ways to synthesize with less impact. Researchers at universities and private labs are playing with catalysts that reduce byproducts, reclaim solvents, and recycle wherever they can. There’s also a strong movement toward digital tracking to record chemical inventories and accidents, helping teams stay prepared instead of reactive.

Why Accuracy Matters

A single wrong symbol in a formula can set back an experiment or put someone at risk. Having the right identity for phenylbromide—C6H5Br—means the difference between safe progress and costly mistakes. Accurate chemical communication underpins safe handling, innovation, and trust in science. From the smell in a beginner’s flask to the last step in a multi-million-dollar drug process, these simple formulas guide real hazards and real breakthroughs, earning every bit of our respect.

Why Proper Storage of Phenylbromide Matters

Anyone who’s spent time in a chemistry lab knows that carelessness around storage often leads straight to trouble. Phenylbromide isn’t the toughest chemical out there, but its volatile nature calls for respect. Letting it sit just anywhere doesn’t only threaten your results, but it can also spark issues for your team and the environment. Leakages and accidental exposures have a way of snowballing into big hassles fast.

The Right Container Makes All the Difference

Every chemist has a story about some old reagent bottle gone wrong. With phenylbromide, glass wins out. Metal and plastic sometimes react badly with organobromides, so sticking with amber glass bottles cuts down on risks. I’ve seen labs where careless use of the wrong plastic triggers contamination or slow leaks. For a compound that can be both toxic and stubborn about leaving stains, tight screw tops with secure seals prevent evaporation and mystery fumes in your storage area.

Cool, Dry, and Out of the Light

Heat and moisture have a knack for wrecking chemicals. Phenylbromide holds up best in cool, dry places. People might laugh off those “temperature controlled” signs, but they exist for good reason. Warmth speeds up decomposition and raises pressure inside the bottle—a recipe for cracked seals or even explosions if ignored long enough. My rule has always been to keep chemicals away from heat sources, up off concrete floors, and nowhere near windows or radiators.

Keep It Separate: No Room for Surprises

Too many labs treat storage as a puzzle game to cram everything into one cabinet. With phenylbromide, giving it dedicated space reduces the chance for accidental mixing or dangerous reactions. Keeping it away from oxidizing agents, strong bases, and acids is a must. I’ve seen containers weep and corrode simply because someone stashed them a row away from nitric acid. Flammable liquids cabinets with proper ventilation, fire resistance, and clear labeling keep cross-contamination at bay.

Training and Labeling: People Make or Break Safety

Checking boxes on a safety checklist doesn’t mean much if nobody knows what’s inside each container. Every bottle at my bench has a legible label with the chemical name, date of arrival, and hazard warnings. If you inherit stock, don’t rely on faded tags or mystery hand-writing. Training everyone on the team to spot problems—cloudy contents, broken seals, or strange odors—gets things fixed before accidents happen. Shared spaces call for a culture shift, not just a monthly inspection.

What Regulations Say—And Why Experience Still Counts

The rules for storing phenylbromide come straight from agencies like OSHA and the EPA. These guidelines weren’t made up to annoy chemists; they reflect what’s gone wrong in the past. Secondary containment trays, spill kits, and fire extinguishers nearby aren’t just for show. In my years of lab work, the teams who go beyond the bare minimum avoid the nasty surprises that make headlines and prompt shutdowns. Regulations play catch-up, but a careful, curious worker always spots trouble sooner.

Steps Forward for Safer Storage

Digital inventory tracking brings some peace of mind. Logging every movement of a phenylbromide bottle, tracking expiry dates, and setting up reminders for checks gives staff a better shot at catching issues early. More companies now look at air quality monitoring in storage rooms as routine. Nobody wants to breathe in trace vapors day after day. Bringing up concerns with management or safety officers shouldn’t feel like bucking the system—it’s the kind of habit that makes the whole workplace stronger, not just safer.

Understanding Where Phenylbromide Fits

Phenylbromide, also known as bromobenzene, crops up in organic chemistry labs. It comes in as a solvent or as a building block for larger molecules. It looks harmless—a clear, colorless liquid that smells a bit sweet. Experience shows, though, that the gentle scent masks some real hazards.

Why Caution Matters

A pint of experience beats a gallon of theory. Anyone who’s accidentally splashed phenylbromide knows it feels oily and spreads quickly. It absorbs straight into the skin, and repeated contact dries skin or leads to redness and peeling. Breathing in the vapors leaves you dizzy, nauseous, or with a headache if you spend too long in a poorly ventilated room. The safety data sheets list its harmful health effects for a reason, so it never makes sense to cut corners with this liquid around.

Gear Up: Gloves, Goggles, and More

Chemical-resistant gloves matter most. Nitrile or neoprene gloves work best—they stand up against the solvent, unlike the cheap latex ones that some labs keep on hand. Always check gloves for holes or signs of wear. Safety goggles block splashes. Ordinary eyeglasses won’t cut it—splashed phenylbromide stings and poses a risk to eyesight. A sturdy lab coat or apron stops the chemical from soaking your clothes and touching skin.

Ventilation Can’t Wait

People sometimes think a cracked window will handle fumes, but it never does. Strong airflow, like a working chemical fume hood, keeps concentrations low. In smaller, closed-off rooms, vapors hang in the air longer than you’d expect. My old college lab lost a fume hood fan for only thirty minutes, and you could taste solvents in the air after. Over time, inhaling vapors may harm your liver or nervous system. That risk matters not just for the lab worker, but for anyone who shares the same space.

Fire Is No Joke

Bromobenzene lights up fast. Storing it near open flames—like a Bunsen burner—or hot equipment is asking for a problem. Always keep tightly sealed bottles in flammable-safe cabinets, away from direct sunlight or space heaters. Many fires start with a careless move near a hotplate. Having an ABC or carbon dioxide fire extinguisher within arm’s reach goes a long way. Water spreads phenylbromide spills and doesn’t put out organic solvent fires.

Never Skip Good Clean-Up Practices

Even advanced students dump tiny spills down the sink. That’s more than a bad habit—catching a whiff of bromobenzene down the drain never does the water system any favors. Always use proper organic waste containers and label your waste bottle clearly. After every use, wash hands thoroughly. Wipe up bench tops with the right cleaning agents, and never leave contaminated equipment lying around for the next person.

Emergency Plans: Better Safe Than Sorry

Eyewash stations and safety showers should never double as places to store empty bottles. Post instructions nearby so anyone—new student or seasoned chemist—knows what to do. If you wear contact lenses, take extra care: a splash of phenylbromide can get trapped under the lens. Quick action, like flushing eyes or skin right away, limits harm. Keeping safety data sheets easy to find helps people know what steps to follow if things go sideways.

Smart Steps Make a Safer Lab

Mistakes happen, but habits build up. Using the right gloves and eyewear, handling the bottle in a good fume hood, and cleaning up thoroughly all add up. Listening to folks who work with solvents daily teaches you simple tricks—like taping down bottle lids or running a fan overnight to clear out old air. If everyone looks out for the basics, burns and exposures become rare stories instead of common ones.