N,N-Diethylaniline: An In-Depth Commentary

Historical Development

Across the chemical industry, stories about compounds echo larger trends in science and technology. N,N-Diethylaniline, a derivative of aniline, reflects the classic path many aromatic amines followed in the late 1800s, when European chemists looked for ways to expand existing dye families. The emergence of synthetic dyes from coal tar unlocked demand for tailored intermediates, and N,N-Diethylaniline arrived out of this growing appetite for novel aromatic amines. Large-scale production began as researchers realized that selectively ethylating the amine group on the benzene ring produced new shades in dye applications. Its synthesis boomed through the 20th century, supported by innovations in both batch and continuous processing in Germany, the United Kingdom, and the United States. The chemical legacy built by these early advances supports countless chemical plants today.

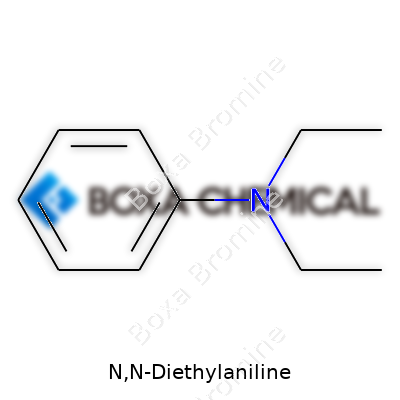

Product Overview

The product N,N-Diethylaniline appears as a pale to yellowish liquid with a mild aromatic odor. Its chemical structure features a benzene ring bonded to a nitrogen atom substituted with two ethyl groups. Many refer to this compound in laboratories and industry by the acronym DEA, but names like N,N-Diethylbenzenamine also appear across datasheets and regulatory filings. Across supply chains, it gets packed in iron drums or high-density polyethylene containers, well-sealed to limit volatility. Chemical companies track high-purity grades (over 99%) for specialized reactions, especially where side-products would spoil downstream reactions.

Physical & Chemical Properties

This compound boils near 215°C and melts at -29°C, so it remains a liquid under most ambient conditions. Specific gravity hovers around 0.93 g/cm3 at 20°C. Its refractive index sits at 1.55. N,N-Diethylaniline dissolves readily in organic solvents such as ethanol, ether, and chloroform, but barely mixes with water. This profile comes from the molecule’s hydrophobic benzene and ethyl groups. Chemically, it acts as a weak base, able to engage in both nucleophilic substitution and electrophilic aromatic substitution reactions. Its electron-rich nature means it participates actively in diverse syntheses, including azo dye preparation. High vapor pressure compared to heavier aromatic amines demands careful handling to prevent escapes in the workplace.

Technical Specifications & Labeling

Chemical buyers and users depend on strict technical specifications for N,N-Diethylaniline. Purity marks a major threshold, with lower grades filtered toward applications like bulk dye creation while higher-purity lots serve pharmaceuticals or fine chemicals. Labels cite the CAS number (91-66-7), molecular formula (C10H15N), and standardized batch analysis: water content under 0.1%, acid/base numbers, residue on evaporation, and absence of specific heavy metals. Companies often require safety data sheets (SDS), documentation of batch traceability, hazard labeling for toxicity and flammability, and transportation codes consistent with emergency regulations.

Preparation Method

Producing N,N-Diethylaniline often starts with aniline, a foundational chemical made from benzene. Industrial processes react aniline with diethyl sulfate or ethyl bromide under basic conditions, using sodium hydroxide and careful control of temperature and pressure. Another established route includes catalytic alkylation using ethanol in the presence of acid catalysts. Yields and side product profiles depend on catalyst choice and reaction time, so many refinements cluster around maximizing conversions and isolating pure N,N-Diethylaniline. Continuous flow methods boost throughput and minimize risks linked with handling bulk alkyl halides, helping newer plants squeeze extra productivity from each reactor.

Chemical Reactions & Modifications

Synthetic chemists value N,N-Diethylaniline not just for its structure but its chemical reactivity. The electron-donating nature of the two ethyl groups steers substitutions toward certain positions on the aromatic ring, encouraging precise modifications. In azo dye synthesis, coupling with diazonium salts creates vivid pigments for textile and ink industries. Oxidative reactions transform the core into quinone derivatives, opening doors for other fine chemicals. Cross-coupling, acylation, and sulfonation approaches serve as classic textbook cases for undergraduate and graduate organic chemists studying aromatic functionalization. Unintended side reactions—especially under harsh oxidizing conditions—can degrade yield, so careful process design earns its place in labs and production halls alike.

Synonyms & Product Names

Chemicals often wear several names, which helps track their use in global trade, research, and different regulatory codes. N,N-Diethylaniline finds mention as Diethylaniline, Benzenamine, N,N-diethyl-, and DEA as shorthand used in paperwork or oral discussion among technical teams. Technical bulletins may mention it as N,N-Diethylbenzenamine or simply as "Diethylaniline" in the context of dye intermediates. Global distributors catalog the compound under its CAS number, supporting traceability and harmonized chemical identification across regions.

Safety & Operational Standards

Plant operators, lab workers, and transport teams face real hazards with N,N-Diethylaniline. The compound delivers toxic effects by inhalation, skin absorption, and ingestion, acting as an irritant to eyes and upper respiratory tracts. Overexposure can depress the central nervous system and, in severe cases, affect the liver and kidneys. Regulatory bodies like OSHA and the European Chemicals Agency (ECHA) lay out strict occupational exposure limits. Reliable PPE—nitrile gloves, goggles, and proper ventilation—stand as non-negotiables in any workspace handling this liquid. Emergency procedures support immediate action in the event of spills, with activated charcoal or absorbent pads playing a role in containment and cleanup. Regular training ensures no gap appears between new hires and long-term staff. Engineers design equipment with pressure relief, vapor recovery, and leak detection to meet both legal and insurance standards, while robust record-keeping enables audits and investigates incidents without guesswork.

Application Area

N,N-Diethylaniline plays a starring role as an intermediate in manufacturing dyes, especially for cotton and synthetic fibers. The electronics industry taps it for charge-transport layers in photoreceptors, supporting printer, copier, and display innovations. In the pharmaceutical sector, it shows up as a building block for antihistamines, local anesthetics, and specialty drug classes. Some agricultural chemical products weave it into their structures, looking to benefit from its modifiable aromatic ring. Research teams sometimes use it as an analytical standard, and it has served as a stabilizer in select polymer manufacturing recipes. The push for greener chemistry practices has prompted some companies to look for alternatives in high-volume consumer goods, yet the specific reactivity and performance of N,N-Diethylaniline mean chemists keep it on their workbenches for custom and high-value tasks.

Research & Development

The field around N,N-Diethylaniline never stands still. Academic work focuses on greener synthesis options, from bio-based ethylation agents to solvent systems that cut environmental impact. Automated reactors enable the testing of catalyst screens and continuous-flow approaches, extracting better yield data from small trial scales. Pharmaceutical researchers, meanwhile, chart the molecule for derivatives that show enhanced biological properties, especially in central nervous system applications. Environmental chemists build analytical methods, including chromatography and mass spectrometry, for measuring trace contamination around plants and in waste streams. Cross-disciplinary projects link materials science with organic synthesis, exploring new families of charge-transfer complexes that use the molecule’s electronic features. The quest continues for safer, cheaper, and more sustainable ways to make, use, and dispose of N,N-Diethylaniline across all these fields.

Toxicity Research

Toxicology studies trace risks to people and ecosystems. Acute and chronic tests on lab animals demonstrate that N,N-Diethylaniline causes irritation and potential organimpact at higher exposures. Researchers use controlled inhalation studies and oral dosing to track absorption, distribution, metabolism, and excretion, mapping how quickly the body clears exposure. Once inside, the compound metabolizes in the liver, with byproducts filtered by the kidneys. Bioaccumulation risk appears low, yet aquatic toxicity studies show harm to fish and invertebrates at relatively low concentrations. Occupational medicine researchers have documented accidental exposure cases, reinforcing the link between vigilance, real-time air monitoring, and lower health impacts among chemical plant workers. Scientific consensus calls for tight regulation in line with other aromatic amines, especially given the compound’s persistence under typical environmental conditions.

Future Prospects

Looking ahead, shifts in manufacturing and environmental priorities shape the outlook for N,N-Diethylaniline. Many dye manufacturers in Asia and Europe continue to anchor processes around this compound, yet regulatory and consumer moves toward safer, less toxic intermediates push companies to explore replacements. Synthetic biology and green chemistry may one day deliver substitutes that keep performance high while reducing employee and environmental risks. Advances in catalysis promise new synthesis pathways with lower energy footprints and less harmful byproducts. Researchers searching for molecules with similar electronic features but cleaner environmental profiles keep N,N-Diethylaniline under scrutiny, driving continuous improvement. Safe handling, meticulous process design, and ongoing research dictate how future generations will use this chemical. For plants and labs facing ever-tighter standards and tougher competition, responsible stewardship stays essential across every branch of the supply chain.

Beyond the Chemistry Set

People tend to overlook chemicals like N,N-Diethylaniline, but its uses stretch farther than most expect. At its core, N,N-Diethylaniline supports several key industries through its role as an intermediate. For someone who grew up around workers in the textile business, the presence of unknown chemicals often drew curiosity. It turns out, this compound gets pulled into action mainly for dye production—particularly for making dyes vivid and lasting on fabric.

The Role in Dyes and Pigments

N,N-Diethylaniline stands out for its contribution to the creation of azo dyes. Millions step into cotton shirts and blue jeans every day without thinking about how those deep, lasting colors land on the fabric. This compound acts as a building block for colors like malachite green and crystal violet. Both of these show up in everything from school microscopes to ink on everyday receipts. Reliable color fastness and high color intensity play a big role in a market measured in billions of dollars annually. The American Chemical Society, among others, notes the dye industry still relies on intermediates like this one for consistent color production.

Printing Inks and Beyond

Offices, printing shops, and packaging companies depend on batches of inks that won’t fade or bleed. N,N-Diethylaniline sits right in the middle of that story. Ink manufacturers use it in the processing and formulation of inks, especially those demanding sharp, clear prints. Packaging for food, medicine, and even mail uses inks with origins tied to this compound. My time working a summer job at a print shop highlighted just how crucial stable ink recipes became. Mess up an intermediate, and entire runs fail quality checks.

Electronics, Rubber, and Pesticides

Its journey doesn’t stop at clothing and books. Manufacturers utilize this chemical to make certain intermediates for pharmaceutical synthesis and agricultural chemicals. In the pesticide segment, it helps prepare organic molecules that protect crops. In electronics, tiny quantities show up when companies synthesize specialized organic compounds used for light-sensitive applications.

The rubber industry holds another slice of demand. By adding N,N-Diethylaniline, chemists create antioxidants that improve shelf life and resistance of rubber products. This matters for both vehicle tires and everyday shoe soles. I remember touring a tire plant as a teenager and hearing about premature rubber cracking—protective chemicals quietly cut down on those product failures.

Handling and Health Concerns

The importance of N,N-Diethylaniline reaches beyond just technical industry use. Its toxicity profile triggers concern among safety experts. Short-term exposure can irritate skin and lungs. Chronic exposure, something factory workers face, increases risk for more serious health issues. Facilities using this compound track airborne concentrations closely. They keep ventilation systems and protective gear mandatory. In my college days, chemical safety drills always named aromatic amines like this one because of their hazardous nature.

Mitigating the Risks

Reducing the hazards linked to N,N-Diethylaniline centers on rigorous workplace controls, education, and seeking safer alternatives. Groups such as the Occupational Safety and Health Administration outline clear protocols for safe handling. Investing in engineering controls and closed processing systems stems major risks. Research pushes toward greener dyes and less toxic intermediates, aiming for both safety and sustainability. Until that shift becomes industry-wide, respect for the risks and commitment to good lab practice count for a lot.

Why Handle N,N-Diethylaniline Carefully?

N,N-Diethylaniline, used in dyes, pharmaceuticals, and sometimes even in research labs, is not your everyday household chemical. Working with it can cause headaches, dizziness, and trouble breathing if you inhale too much. Skin irritation and burns happen fast if it splashes. The chemical can get into your eyes and do serious damage. After years of working around industrial labs, stories aren’t rare about smart people ending up in the ER because steps got skipped. Treating chemicals like this with respect keeps you healthy and avoids a surprise trip to the doctor.

Good Ventilation Saves More Than Comfort

Fumes from N,N-Diethylaniline build up quick, and the smell can make your eyes water. But the real danger hides in what you can’t smell. A well-designed fume hood pulls vapors away from your breathing space. Crack open the lab windows or keep the extractor running. Don’t trust instincts alone — use an air flow monitor or smoke tubes to make sure the hood does the job. Some older facilities rely on guesswork, which never ends well. Modern science supports solid airflow for a reason.

Gloves, Goggles, and More than a Lab Coat

Hands are always on the front lines in a lab. Chemical-resistant gloves — think nitrile or neoprene — give a layer of protection that regular latex can’t provide. Changing gloves often prevents the thin membrane from thinning out or holes sneaking in. Eyes need much more than standard glasses. Wrap-around goggles keep splashes out, and face shields go the extra mile if you’re pouring larger amounts. A lab coat sounds good, but actual splash-resistant lab gear beats a coffee-stained cotton jacket every time. Years of working with solvents convinced me quickly.

Plan for Spills — Not Just Once, Every Time

Spill kits feel like overkill until liquid lands on the counter. Sand, absorbent pads, and neutralizers specific for organic solvents take seconds to grab if you store them near the workbench. Practice makes perfect: occasional drills train your hands to move without thinking. Old stories float around about labs that waited for help instead of just grabbing a kit. Quick action stops the chemical from seeping into cracks or running into floor drains.

Storing N,N-Diethylaniline Safely

Chemicals like this deserve lockable, ventilated cabinets. Store away from acids and oxidizers. Don't keep glass containers on high shelves. Put spill trays beneath containers to catch drips. At one old job, someone tried to store it near bleach. The two together create a mix dangerous enough to trigger evacuations. Clear labels help everyone — especially at the end of the day when your attention starts to fade.

Waste Disposal—Not for Cutting Corners

Pouring it down the sink just creates bigger problems for the water system and anyone downstream. Local laws cover disposal rules, so check them out. Many facilities have chemical waste tags and logbooks that make tracking simple. After handling a bad spill myself in a busy lab, I learned nobody likes the scent of N,N-Diethylaniline showing up in the air conditioning days later. Secure containers with tight-fitting lids close the loop on safe disposal.

Respect, Not Fear

Handling N,N-Diethylaniline well doesn’t require fear or paranoia. It just takes planning, good habits, and enough respect for both the chemical and the people beside you. The more you practice the basics, the more routine safety becomes. That’s how to keep science and personal health working on the same team.

N,N-Diethylaniline—More Than Just a Name

N,N-Diethylaniline doesn’t usually show up in daily conversation unless chemistry’s on the table. Behind the long name, you find a chemical that shapes things you might never expect, from dyes to pharmaceuticals. It pops up in labs and factories, becoming a building block for all kinds of chemical reactions. The exact question—what is the chemical formula—matters for anyone working with it, storing it, or making something new out of it.

Chemical Formula: C10H15N

Straight to the facts: the formula for N,N-Diethylaniline is C10H15N. This tells you a lot before even seeing the molecule itself. You’ve got ten carbon atoms, fifteen hydrogen atoms, and one lonely nitrogen atom. Every part of the name points right back to this formula. Each “ethyl” means two carbon and five hydrogen are tagged onto the nitrogen, which itself connects directly to the benzene ring of aniline. That classic structure lets it slip into organic syntheses or colorant production.

Why the Formula Matters

Knowing this formula saves time and money. If you’re making industrial dyes or working in a research setting, every atom counts for safety labels, chemical reactions, and regulatory paperwork. N,N-Diethylaniline’s makeup means it acts as an organic base and can be toxic in certain conditions. Facts back it up—OSHA and the CDC lists stress safe handling, and even small spills require care because of its ability to absorb through skin or evaporate into the air.

Handling Risks and Real-World Impact

Ignoring chemical formulas ends up costing more. My own time in the lab hammered this in—labels might smear, but remembering C10H15N unravels a chain of decisions, from safe storage to emergency procedures. Hazards aren’t just some hazy problem for other folks; inhaling or touching this compound can trigger nasty symptoms. That’s why so many protocols lean on understanding molecules all the way down to their atoms.

Fact-Driven Solutions and Recommendations

Anyone who handles N,N-Diethylaniline long enough can point to near misses and learnings. Thinking ahead means treating the formula as a flag—use gloves, ventilate spaces, and always double-check labels. Fact sheets from health institutions highlight the importance of correct handling, and recent studies from academic journals support extra care in ventilation to lower inhalation risk.

Regulation offers a safety net. Companies benefit from training that runs through chemical names right alongside formulas. High schools and universities should root the basics early—students who remember C10H15N connect that knowledge straight to hands-on lab work. Mistakes drop in frequency once you respect the fine print of each molecule.

Building Trust Through Science

Credibility comes through experience, documented best practices, and scientifically-backed steps. For N,N-Diethylaniline, understanding its formula is more than trivia. Industry and research professionals treat this as essential knowledge for safe processes and responsible chemical innovation. As new uses emerge in pharmaceuticals or green chemistry, knowing what sits behind the name gives teams the confidence to create and protect at the same time.

Why This Chemical Matters in Everyday Labs

N,N-Diethylaniline pops up in research labs, dye manufacturing, and sometimes in specialty chemical production. It doesn’t grab headlines like volatile gases or caustic acids, but it has its quirks. From firsthand experience handling aromatic amines, safety sometimes gets overlooked because the name doesn’t sound threatening. Years in the lab taught me that taking shortcuts leads to spills, strange odors, and uncomfortable conversations during audits.

Risk Factors That Deserve Respect

N,N-Diethylaniline falls under the category of hazardous chemicals. It's a flammable liquid and can evaporate enough to pose an inhalation risk. Skin contact and eye exposure bring on irritation fast. The fact that you probably rarely hear about it in the news shouldn’t fool anyone into complacency. OSHA and NIOSH both flag chemicals like this for a reason—casual storage will set the stage for workplace injuries.

Steps to Reliable Storage

Keeping N,N-Diethylaniline safe starts with the right container. Use tightly sealed glass or compatible HDPE bottles. These resist chemical attack and won’t slowly degrade the way some plastics do. At a previous job, a colleague made the mistake of using a bucket-grade plastic container. One month later, that container started to soften, odor leaked out, and suddenly the small storage room smelled like a chemistry set gone wrong.

Place these containers away from direct sunlight. Heat speeds up vaporization, boosting the risk of flammable vapors building up. Store it cool—ideally below 25°C—since we found even modest heat from nearby equipment increased vapor pressure inside the bottle.

Ventilation and Segregation

Flammable liquids need separation from oxidizers and acids. One time, a batch of chemicals sat too close to an old bottle of nitric acid, and humidity in the room created rust and made warning labels peel. That experience drove our team to reorganize shelves and invest in metal safety cabinets built for flammable liquids. Even a small investment in proper storage keeps surprises at bay.

Ventilation plays a huge role. N,N-Diethylaniline can vaporize enough to trigger headaches or worse. Avoid small, closed storage rooms without forced air flow. Always add chemical storage signs that tell custodians and new staff what’s inside. Training up a new hire without mentioning the risks of aromatic amines almost guarantees they’ll learn the hard way.

Labelling, Spills, and Regular Checks

Every container should have a durable, chemical-resistant label, not just a marker that wipes off. Lab audits make it crystal clear—good labeling saves time during emergencies. Set up regular inspections to check for leaks, deterioration, or pressure build-up. We made it routine to rotate inventory and dispose of old stock well before expiration. Once, a forgotten half-liter bottle broke during a move and cost hours in cleanup and a mountain of paperwork.

Handling spills means using chemical absorbent pads and a fume hood if possible. Standard gloves (like nitrile) and eye protection go from “optional” to “non-negotiable” when working with this compound. After every interaction, clean up tools and surfaces with soap and lots of water.

Simple Steps Save Headaches

Storing N,N-Diethylaniline doesn’t have to be complicated, but it does call for respect and common sense. Good containers, clear labels, cool storage, and proper ventilation form the foundation. Walk through the lab and check: old habits slip in faster than most realize. Take it seriously, and it becomes background noise—one less thing to worry about during the busy rush of research or production.

What Science Says about N,N-Diethylaniline

N,N-Diethylaniline shows up in news cycles whenever chemical safety grabs headlines. It sits in labs, factories, and even some everyday products. Chemists know this compound as a clear liquid with a fishy odor, used to make dyes and sometimes as a chemical intermediate. On paper, it sounds like just another ingredient, but experience says a label doesn’t always tell the whole story.

Health and Environmental Concerns

Breathe in the vapors, and there’s a good chance your body won’t thank you. Many people working around it report trouble with their eyes, nose, and throat. Some go home with headaches, dizziness, or worse if ventilation slips. Skin and eye contact can cause real irritation. Spill enough to soak through clothes, and it causes redness or swelling. Research points toward bigger problems with large doses: some animal studies link this chemical to organ damage, specifically in the liver and kidneys. That worries anyone who knows someone with chemical sensitivities.

Cancer Risk and Long-Term Safety

It’s reasonable to ask if N,N-Diethylaniline causes cancer. Risk analysis comes from both animal testing and looking at industrial cases over time. Some evidence kicks up concern since similar compounds have a record of causing tumors in lab animals. Yet, toxicity data for humans remains incomplete. Scientists urge caution, saying it makes sense to limit unnecessary exposure since the chemical structure resembles others flagged as possible human carcinogens by health agencies.

How People Get Exposed

Exposure doesn’t just happen in a research lab. Factory workers face the highest risk, especially if safety controls drop or spill response takes too long. People using certain hair dyes or photographic chemicals at home might handle the compound by accident. Air quality inside plants can turn risky fast without good ventilation or proper masks. Wastewater disposal also creates risks for local communities if factories discharge untreated byproducts. Regular folks hardly hear about it, but anyone living nearby a plant could experience low-dose exposure over years.

How to Lower the Risk

Strong safety rules matter here. Facilities handling N,N-Diethylaniline must invest in working fume hoods, gloves, goggles, and chemical-resistant clothing. Training every worker on emergency cleaning procedures changes outcomes in a chemical incident. At home, follow directions for all powders, liquids, or dyes you buy. Read up on ingredients before use, because manufacturers sometimes sneak in additives under broad terms like “aromatic amines.”

Communities also depend on strict regulations for chemical emissions and wastewater treatment. Local governments checking discharge reports and monitoring air quality keep surrounding neighborhoods safer. Public records and right-to-know laws should open up information on chemical use in every town, making it easier for people to ask questions or push for stronger policies.

Making Choices with Chemicals in Mind

Anyone spending years in industrial chemistry knows accidents can happen, even on well-run sites. I’ve met folks who got a raw deal after working with chemicals like N,N-Diethylaniline before modern rules came into play. Things improved only after workers demanded honesty about long-term health effects and fought for better safety standards. Now, regulatory agencies keep pushing for transparency, though gaps in research still exist. Good science always questions, compares, and tests—trust should never come easy where health risks remain uncertain.