N-Methylmethanesulfonamide: Understanding a Key Industrial Chemical

Historical Development

Interest in sulfonamide chemistry has always shaped major chapters in the story of organic synthesis. By the late 19th century, advances in manufacturing sulfonamides spurred new possibilities for both pharmaceuticals and chemical intermediates. During the 20th century, N-Methylmethanesulfonamide found its place as a workhorse for researchers searching for milder reagents, adaptable solvents, and specialty monomers. The combination of a methyl group on the nitrogen and a methanesulfonyl group on the same molecule, while simple, has meant extensive synthetic utility. Chemists in Germany and the United States in the 1960s and ’70s homed in on derivatives like this one for their low reactivity toward oxidation and reliable performance supporting various reactions.

Product Overview

N-Methylmethanesulfonamide offers more than its basic makeup might suggest. At first glance, it sounds like any other sulfonamide. But in practice, it combines moderate polarity with water solubility, giving it a role as both solvent and intermediate. Its formula, CH3SO2NHCH3, hides an ability to dissolve stubborn organic and inorganic substances alike. The compound’s liquid state at room temperature adds convenience, compared to related solids that need gentle heating to process. In terms of supply, reputable chemical vendors sell it in technical and high-purity grades, recognizing its diverse roles in manufacturing and research. Years of use have shown that this colorless or pale liquid stands steady across settings from organic labs to pilot-scale operations.

Physical & Chemical Properties

This molecule has a molecular weight around 109 g/mol. It stays liquid from below freezing all the way past 100°C, reflecting a boiling point above water and a freezing point near -30°C. Its moderate polarity makes it mix well with water, alcohols, and other polar organics. Unlike most amides, it resists hydrolysis in acidic and neutral water, holding up to basic environments for short periods too. The methyl and sulfonyl groups don’t readily react unless provoked with strong acids or oxidants. With vapors heavier than air, ventilation remains important in confined spaces, even though its volatility stays moderate. Years in the lab have shown that it withstands rough and tumble handling better than most, with little tendency to decompose or burn under normal conditions. Its mild sulfur smell sets it apart from the more aggressive scent of most small amines.

Technical Specifications & Labeling

N-Methylmethanesulfonamide comes with tight purity controls, especially for pharmaceutical applications. Standard assay runs at least 98% or higher, with traces of moisture and related impurities listed on the certificate of analysis. Labels typically include the UN number for laboratory chemicals, storage recommendations of cool, dry, and well-ventilated, and reminders to avoid direct sunlight. Safety data sheet (SDS) entries point out incompatibilities with strong oxidizers and reducing agents. I’ve shipped and received samples in both plastic and glass bottles with no sign of leaching or degradation, although plastic wraps are best for the long haul.

Preparation Method

In the chemical plant, production usually starts from methanesulfonyl chloride and methylamine. The process has a reputation for running reliably in either batch or continuous mode. Methanesulfonyl chloride reacts cleanly with excess methylamine under anhydrous conditions, giving N-Methylmethanesulfonamide and hydrochloric acid as a byproduct. Some laboratories funnel the crude product through a water wash and solvent extraction to knock out side products or overalkylated impurities, all before distilling under vacuum to polish it off. From small bench-scale to thousand-liter reactors, the simplicity and directness of this method keep production costs low and batch-to-batch differences minimal.

Chemical Reactions & Modifications

One reason this molecule appears in research is its robust resistance to most reaction conditions. It can accept alkyl or acyl groups on the nitrogen, forming N,N-disubstituted derivatives for specialty purposes. Most oxidizing acids do little, because the sulfonyl group sits about as oxidized as sulfur can get. Reduction takes tough chemistry, usually strong hydrides or catalytic hydrogenation under forceful pressure. As an amide, the molecule can also step in for base-promoted coupling and urea formation, though I’ve always found it slow unless heated above 100°C. The nitrogen lone pair opens it up to many transition-metal catalysis pathways, especially as a ligand or supporting solvent.

Synonyms & Product Names

Depending on which catalog you look at, N-Methylmethanesulfonamide travels under a range of names. Common alternatives include N-Methylmethanesulphonamide, Methyl(methylsulfonyl)amine, and Methanesulfonic acid N-methylamide. Across patents and literature, the product number and CAS number (124-39-2) often accompany the name to prevent mix-ups. It’s always worth cross-checking, especially when chemical suppliers describe grades for specific industries, from electronics to pharma synthesis.

Safety & Operational Standards

Long hours in the lab reveal that N-Methylmethanesulfonamide behaves with a low flammability risk and little acute toxicity. Still, like many sulfonamides, its dust and vapor may irritate eyes, skin, or upper respiratory tract. Safety goggles and gloves take the edge off most direct contact issues. Spills clean up easily with absorbent materials; no need for specialty hazmat gear unless you’re working in bulk. Prolonged exposure or ingestion brings risks that echo those of other aliphatic sulfonamides, meaning long-term inhalation or skin contact isn’t wise. For large storage volumes, sealed steel or high-density poly drums lock out moisture and air. Process controls focus on ventilation, splash protection, and keeping incompatible materials at bay. My experience matches up with published reports: this compound stands on the safer side of the spectrum among industrial amides.

Application Area

This chemical finds action all over the map. Industrial-scale chemistry taps it as a stable polar aprotic solvent in drug development and catalyst screening. Polymer manufacturers blend it in as a monomer or chain extender, especially for performance resins or specialty elastomers. Electrochemists turn to it when they need a chemically inert, hydrophilic solvent that shrugs off most redox conditions. In pharmaceuticals, it assists in selective acylation and N-alkylation reactions as an additive or protecting group. Agrochemicals and dye chemistry sometimes adopt it for sulfonamide-based structural frameworks. My former team used it as a support solvent for peptide synthesis, because it barely interferes with coupling agents or resin-swelling protocols. Reports from industrial users show it enduring in cleaning formulations, where the mix of water solubility and chemical resistance helps strip away persistent organics.

Research & Development

Academic and industrial teams dig deep into N-Methylmethanesulfonamide’s unique reactivity. In the last decade, its role as a base-stable intermediate has grown in green chemistry, including work on recyclable solvents and catalysis systems that shun traditional chlorinated organics. Nanotechnology researchers use it to functionalize graphene and carbon nanotubes for better dispersibility in water or polar polymers. Its low toxicity and reactivity expand the toolkit available to biotech researchers, especially in synthesis routes for new drugs with fewer environmental hazards. Formulation scientists still tinker with blends for advanced materials, focusing on its effect as a reactive diluent and modifier for polymers with demanding performance benchmarks. Many working in the field tell me it’s the unpredictably simple molecules like this one that spark new lines of inquiry.

Toxicity Research

Like many small-molecule amides, most animal studies paint N-Methylmethanesulfonamide as low-hazard, both for acute and chronic exposure. In vitro tests rarely show significant mutagenicity or cytotoxicity on a scale comparable to alkyl sulfonamides. Restrictive thresholds exist mainly for workplace settings, not for environmental contamination, and spills break down in nature within a few days under aerobic conditions. Staff training emphasizes general chemical hygiene, not heightened alarm. Still, research pushes forward on long-term exposure risks, especially for those producing or transporting tons at a time. The European Chemicals Agency and corresponding U.S. agencies are keeping a watching brief, but as of now, most published studies find little cause for worry beyond the usual common-sense precautions.

Future Prospects

The future looks steady for N-Methylmethanesulfonamide. New regulations on workplace solvent exposure and environmental impact are pushing chemists toward precisely this kind of compound, which balances solvency with low human and ecological toxicity. Work continues on more efficient synthetic routes, aiming to cut out hazardous reagents and lower energy costs. Analytical chemists expand applications into lithium battery electrolytes and as a plasticizer for medical-grade materials. In the world of green chemistry, the molecule gets play as a component in recyclable solvents and sustainable reaction systems. Collaboration between industry, academic labs, and regulatory bodies guides responsible innovation and transparency, keeping safety data and performance benchmarks in open view. Lessons from decades of safe use and reliable synthesis set the stage for broader application, as more sectors appreciate both the versatility and the down-to-earth practicality of this unassuming sulfonamide.

What Role Does N-Methylmethanesulfonamide Play in Industry?

N-Methylmethanesulfonamide has carved out a spot in modern chemical manufacturing as a reliable specialty solvent. It shows up on the ingredient list for a range of processes, but most folks outside chemistry labs haven’t heard of it. My first run-in with this chemical was in the context of pharmaceuticals, where its ability to dissolve both polar and non-polar substances proved valuable. Letting scientists create cleaner reactions and more effective mixtures matters, especially with so much riding on purity and quality in drug development.

It’s not only about pharmaceutical uses. This compound can improve the synthesis of certain agrochemicals, those products farmers count on to protect and nourish crops. Precision and control in the lab mean safer, more predictable results in the field. That matters when looking to feed a growing population. Being stable and chemically compatible, N-Methylmethanesulfonamide sidesteps problems that arise with more reactive or unpredictable solvents. That’s an edge that some other compounds fail to deliver.

Real-World Value in Everyday Products

N-Methylmethanesulfonamide sits in the toolkit of companies making electronics, specifically in battery manufacturing and advanced materials. Take lithium-ion batteries—I’ve seen firsthand how purity at every stage shapes battery safety and longevity. A solvent like this helps engineers avoid contamination issues that can lead to recalls or device failures. In a world packed with portable gadgets, even small shifts in reliability quickly make headlines, so a steady, proven solvent catches the eye of quality managers.

Ink and coating production rounds out its applications. The need for precise and controlled properties in printing inks and specialty coatings sometimes brings manufacturers to N-Methylmethanesulfonamide. If an ink spreads too quickly or dries streaky, costs go up and customers lose faith. A precise solvent often translates into fewer headaches down the road—something printers and coaters value in a tight-margin industry.

Safety and Environmental Responsibility

No powerful tool comes without risk. With a chemical like N-Methylmethanesulfonamide, safety measures matter. It doesn’t pose massive health risks in a lab or factory setting if handled properly, but mishandling any solvent brings hazards. Good ventilation, gloves, and eye protection go a long way in keeping workers safe. Having seen both careful operations and rushed shortcuts, I can say that mistakes often stem from skipping simple steps—something a robust training program can help fix.

On the environmental side, responsible disposal and limited emissions are key. Regulations across the world, including rules set by agencies like the EPA or REACH in Europe, push companies to keep solvents out of the water table and air. Regular safety audits and smart storage help keep accidents from happening in the first place. Manufacturers who take this to heart build stronger reputations with both the public and their industry peers.

Moving Toward Safer Alternatives and Smarter Use

Green chemistry calls for less toxic, more sustainable alternatives wherever possible. Sometimes, N-Methylmethanesulfonamide remains the best fit in a technical sense, yet researchers continue to test biobased solvents that can do the same job. Labs and factories should regularly review their chemical inventories, not just for compliance, but to see where alternatives might simplify processes or cut down on waste. Change isn’t easy, but every step toward smarter solvent use leaves the environment and workers better off.

Looking Past the Basics

N-Methylmethanesulfonamide, often showing up in chemists' labs and production plants, rarely gets much attention outside specialized industries. People handle it mostly as a solvent, especially when working with pharmaceuticals, agrochemicals, or polymer science. This obscure status sometimes leads folks to leave safety on the back burner. I remember my early lab days: the more routine a chemical seemed, the easier it was to grow careless. That's a risky game with substances that haven’t been studied as deeply as staples like acetone or ethanol.

What We Actually Know About Toxicity

Reliable toxicity data for N-Methylmethanesulfonamide remains limited. Major chemical safety databases such as the ECHA Classification & Labelling Inventory and PubChem mark it as a substance that can irritate skin and eyes and to trigger some respiratory discomfort if inhaled. Acute oral and dermal toxicity studies in animals show low toxicity, but these reports cover single, high doses, not the long-term story. Gaps in research make it hard to judge the risks of repeated or low-level exposure over time.

Experience shows that lack of full data doesn’t mean safety. Look at substances like trichloroethylene or formaldehyde—thought largely benign in their early days, regulation tightened once the effects of chronic exposure took center stage. Catching up on safety always feels harder than doing the right thing early.

Sensible Safety Measures

Workplace use has its own demands. Most labs and plants rely on industrial hygiene basics: goggles, gloves, and a fume hood or exhaust vent. The US Occupational Safety and Health Administration (OSHA) and Europe’s REACH framework don’t set clear exposure limits for N-Methylmethanesulfonamide yet. This policy lag leaves a lot up to companies and lab managers. I’ve seen good safety culture in places that expect the unexpected, treating all unfamiliar chemicals as deserving of caution.

Accidents rarely wait for the right time. Even if a chemical lacks the ominous skull-and-crossbones label, its effects can take years to surface. The best workplaces never take short cuts on training or personal protective equipment, because “unknown” on a data sheet rarely means “harmless.”

Environmental and Health Impacts

Dealing with chemical waste grows trickier every year. N-Methylmethanesulfonamide doesn’t show up on major lists of persistent or bioaccumulative toxins, but nobody has mapped its full journey from factory drain to streambed. Most facilities gather N-Methylmethanesulfonamide waste for incineration or specialist disposal. This approach minimizes environmental drift but works only when everyone stays vigilant about proper segregation and storage. Taking a closer look at downstream effects makes sense, especially in communities that have suffered from past chemical spills.

Consumer risk sits low, since everyday folks don’t run into this solvent at the store. Problems mostly stay workplace-centered, unless materials or products made with N-Methylmethanesulfonamide leak into the wider environment through spills or improper dumping.

Building a Safer Tomorrow

Responsible chemical use depends on more than ticking boxes or following yesterday’s rules. My field experience says that seeking up-to-date toxicity studies, pushing for better safety standards, and treating less familiar chemicals with the respect they deserve saves time, lives, and reputations. For anyone working with N-Methylmethanesulfonamide, good habits—regular monitoring, solid training, correct labeling and storage—far outweigh the risks posed by incomplete data. The less we rely on luck, the less likely we’ll find this chemical at the center of tomorrow’s environmental health debate.

Why Paying Attention to Storage and Handling Matters

N-Methylmethanesulfonamide isn’t a compound most people bump into at the grocery store, but in the lab or industrial world, folks take it seriously. It stands as a key ingredient in certain chemical syntheses, and the way we store and handle this kind of substance could mean the difference between a safe workplace and a hazardous one. Speaking from years of organizing cramped chemical closets and walking the fine line between too cautious and not enough, a careful approach feels non-negotiable. I’ve seen what happens when good practice slips—nobody wants the folk in hazmat suits showing up.

Keeping N-Methylmethanesulfonamide Out of Trouble

The big worry is always about avoiding reactions that no one asked for. This chemical loves its dry, cool, and dark corners. Direct sunlight tends to play tricks on stability, and extra heat opens the door to slow degradation or even volatile behavior. Placement in a standard chemical cabinet works, but anything sitting above room temperature for too long nudges up the risk without bringing any practical gain.

Humidity should sit at a low level. From experience, even relatively stable organics draw moisture like a magnet, which sometimes leads to clumps, off-odors, or more annoying surprises. Some labs use desiccators, some just check the weather reports before opening the drum. Either way, protecting chemicals from moisture does more than just maintain shelf life; it shields your team from potential exposure to unpleasant byproducts.

Sealing Containers Is as Much About Safety as About Savings

Seals matter. I’ve seen half-closed bottles thrown back on a shelf and picked up later with crust around the rim and contents no longer trustworthy. N-Methylmethanesulfonamide comes in tightly capped containers for a reason. Keeping that seal intact does two things: it preserves the chemical and keeps any vapors or accidental spills from spoiling air quality or starting reactions with other stored materials.

Handling with Confidence Reduces Headaches Later

Nitrile gloves, splash goggles, and a well-fitted lab coat stand as bare minimums. No one needs chemical burns on their hands or ruined clothing. Even if exposure reports remain low, it doesn’t pay to underestimate skin or eye contact risks. Spills can escalate fast—once, a tiny amount splashed onto a metal spatula etched marks I could never buff out, reminding me how quickly these compounds show their strength.

Ventilation deserves constant attention. Relying on an exhaust hood, even if the substance seems docile, adds a layer of confidence against unpredictable fumes. I’ve learned the hard way that good airflow keeps a workspace from turning into a chemistry experiment gone sideways. Proper labeling also cuts confusion; swapping bottles or failing to note the date on a new container means mistakes creep in too easily.

Disposal and Procedure Matter as Much as Storage

Disposing chemical waste correctly protects everyone down the line. Dumping N-Methylmethanesulfonamide down a regular drain? Not an option. Most places require detailed records and a specialized pickup crew. Sticking to protocols keeps regulatory headaches at bay and builds trust among colleagues who depend on each other's care.

Creating a checklist for storage and handling turns guidelines into routine. It isn’t about paranoia—it’s about respecting the power and unpredictability carried in a bottle of N-Methylmethanesulfonamide. Safe storage and sharp handling habits save budgets, reputations, and sometimes lives. If this mindset becomes second nature, you never need to panic in the first place.

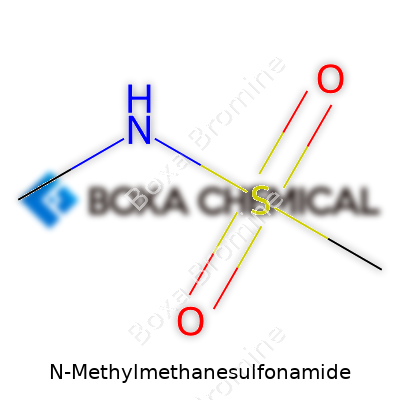

Chemical Identity: Formula and Structure

N-Methylmethanesulfonamide has the formula C2H7NO2S. The name gives away a lot about the structure. There's a methyl group attached to a nitrogen, and that nitrogen bears a sulfonamide linkage. In sketches, the structure looks like this: the central nitrogen holds a methyl group (–CH3), a hydrogen, and bonds to a sulfonyl group (–SO2–) attached to a methane (–CH3). Written out, you’d see something like CH3SO2NHCH3.

Why the Details Matter in Chemistry

Chemical structures don’t just fill textbooks. They guide real decisions in labs, scale-up facilities, and even regulatory agencies. Under the hood, the sulfonamide functional group, present in N-Methylmethanesulfonamide, affects how the molecule behaves. These compounds often show up in pharmaceuticals, but also play quiet, essential roles in synthetic chemistry as stable intermediates or solvents for reactions that need a little extra zing.

Chemists love tools with predictable properties. N-Methylmethanesulfonamide is known for being polar and pretty soluble in water. This helps reactions that need an extra push dissolving ionic ingredients. That basic nitrogen can act as a mild base, and the sulfonyl group resists most breakdown, which gives this compound more durability compared to regular amides.

Connecting Structure and Safety

Sulfonamides come with benefits, but they’re not risk-free. Lab experience teaches respect—especially around nitrogen-containing compounds. The methyl and sulfonamide groups mean this chemical isn’t especially volatile, so you’re unlikely to lose the whole bottle to evaporation or fire. Still, you don’t treat it like table salt. Proper labeling, tight lids, and gloves are standard. I’ve seen new researchers forget that compounds with a methyl group on nitrogen can sometimes be tricky if combined with strong bases or oxidizers, so double-checking compatibility before mixing saves headaches later.

Uses and Influence in the Lab

Over years spent in research settings, I’ve watched N-Methylmethanesulfonamide selected for tough reactions—like promoting nucleophilic substitution or stabilizing sensitive transition states. In a few syntheses, its unique combination of solubility and chemical stability beats more common sulfonamides. Peptide chemists and pharma developers lean on this molecule where a mild, reliable amide is needed, and solvents like dichloromethane won’t do.

One time, a project hit a wall because other amides kept breaking down. Swapping in this molecule kept the whole run stable, boosted our yield, and kept toxic byproducts out. That impressed everyone—especially since greener chemistry and waste reduction get a bigger spotlight nowadays.

Challenges and Possible Directions

Sourcing specialty chemicals like N-Methylmethanesulfonamide isn’t always smooth. Lab managers juggle purity, cost, and lead time. Knock-off suppliers sometimes sneak in lower-purity product, which can mess with sensitive syntheses. Lab teams build trust with reliable suppliers, and some universities now test every incoming batch. I once caught a fake batch by spotting a faint off-white color—experience saved the day, but a better process for on-site testing or tamper-proof bottles would save more labs from ruined experiments.

Disposal creates another hurdle. Sulfonamide waste sits under strict controls in many places due to its toxicological profile. Solvents and residuals need full collection and specialized processing. Training researchers and students on safe handling, storage, and disposal makes for a safer lab and happier regulatory visits.

Future in Chemistry and Industry

With green chemistry gaining importance, there’s pressure for safer, more sustainable amides and sulfonamides. Companies and universities are both pushing for synthesis routes with fewer toxic byproducts and easier waste treatment. N-Methylmethanesulfonamide offers a compelling step, thanks to its chemical backbone and practical behavior in lab reactions. Tighter supply chains, new purification methods, and a focus on environmental stewardship may give this “simple” molecule an outsized impact in chemical development over the next few years.

Understanding the Risks from Real-World Lab Work

Working in the lab often feels routine. Lined up on the shelves, each bottle comes with its own list of hazards—one you ignore only at your own risk. N-Methylmethanesulfonamide stands out for its potential to irritate skin, eyes, and lungs. Colleagues and I have learned that even short exposure can turn a simple day in the lab into a rush for the safety shower. You can’t smell trouble here, but the risks pile up if skin or eyes go unprotected. The guidance is clear because real injuries have happened when people traded comfort for shortcuts.

Why Proper Gloves and Eye Protection Are Non-Negotiable

The moment I open a container of N-Methylmethanesulfonamide, the gloves go on. Nitrile gloves, not latex—because N-Methylmethanesulfonamide can sneak through thinner or poorer quality gloves and cause skin itching or burning. I have seen smart chemists discover holes in their glove protocol the hard way, right when they needed protection most. Glove manufacturers share breakthrough times, and experience proves thinner gloves don’t last as long against solvent mixtures or pure chemicals.

Eye protection makes all the difference. Accidents happen fast, and a single splash sends you down a painful path. Goggles—not just safety glasses—keep liquids out even if you lean over a beaker or flask and get caught by a stray drop. Splash goggles wrap around the eyes, sealing off the route that causes burns or intense discomfort. Chemical burns are more than a nuisance; they mean lost time, ER visits, and sometimes lasting injury.

The Role of Lab Coats and Ventilation

Lab coats seem basic until you see someone without them end up with ruined clothes. N-Methylmethanesulfonamide can soak through light fabric fast, landing close to vulnerable skin. I never forget the smell of burnt fabric or the sight of a ruined shirt—protective coats are a cheap fix. Choose ones with tight cuffs and snap fronts, and launder them away from home clothes to keep possible contamination in check.

Lab ventilation gives another layer of safety. A chemical fume hood draws hazardous vapors away from breathing space. Personal experience has taught me that the right hood setup makes accidental exposure far less likely. Sharing a crowded lab without a good hood means risking your lungs, especially during clean-up or transfer. Labs I trust insist on working with N-Methylmethanesulfonamide inside a functioning fume hood every single time.

Education and Culture Make the Difference

Equipment alone won’t protect you if nobody enforces the right use. Some of the hardest lessons in lab safety happened when someone thought minor shortcuts didn’t matter. Training sessions I attended worked best when they went beyond lists, showing real-life mistakes and fixes. Stories from injured coworkers hit harder than signs on the wall. Building a strong culture—one where questions about PPE get real answers—increases safety far more than posters or checklists alone.

Supporting Facts from Safety Data

Materials safety data sheets and occupational safety standards point toward these practices for a reason. Regulatory agencies like OSHA recommend gloves, goggles, and proper ventilation based on documented injury cases and chemical toxicity studies. Every step I’ve described above has roots in evidence. A habit of reviewing updated safety data keeps my routine current and alert to new information.

Small Choices Stack Up

Memories of skin rash, ruined sleeves, and urgent, panicked eyewash sessions shape my approach to N-Methylmethanesulfonamide. People who do the right thing—right gloves, sealed goggles, proper coats, good hoods—almost never visit the nurse. Safety doesn’t rely on luck; it stands on knowledge, good equipment, and never letting up on careful habits.