N-Ethylaniline: Deep Dive Commentary

Historical Development

N-Ethylaniline’s roots stretch back to the explosive growth of organic chemistry in the later nineteenth century, when coal tar products changed everything for dyes, plastics, and modern pharmaceuticals. Synthetic chemists in those early laboratories looked constantly for new ways to tweak aniline, searching for more vibrant colorants and more effective drug intermediates. With its ethyl group attached to the nitrogen atom, N-Ethylaniline represents one of the earliest—and simplest—modifications of aniline itself. Commercial production began to scale up in the early twentieth century, feeding the demands of the European dye industry and helping to launch a broader set of organic intermediates able to shape industries from rubber processing to industrial paints.

Product Overview

N-Ethylaniline today comes into play across a surprising range of fields. It finds use as an intermediate in dyestuff manufacture, as a corrosion inhibitor, as an antioxidant for lubricating oils, and as a chemical building block in pharmaceuticals. Industrial suppliers typically deliver it as a colorless to slightly yellow oily liquid, packing the strength of aniline’s chemical backbone with the twist of ethyl substitution. The shift from a laboratory curiosity to a mass-produced industrial staple tells a story of chemistry moving directly from experimental benches to mass production lines, and from there into everything from tire factories to ink plants.

Physical & Chemical Properties

N-Ethylaniline’s molecular formula stands as C8H11N, with a molar mass of about 121.18 g/mol. The substance boils at 215–217°C, melting at −70°C, and presents a density of roughly 0.95 g/cm³. The oily, aromatic liquid is only moderately soluble in water, but dissolves easily in organic solvents such as benzene, ethanol, and ether, reflecting those familiar patterns in amines. One sniff and the sharp, fishy odor becomes instantly recognizable—a clear flag for both chemists and anyone caught off guard in the lab. That telltale smell reminds me of the safety lessons drilled into every undergraduate chemist: ventilation and proper handling always trump any rush to meet deadlines.

Technical Specifications & Labeling

Producers typically label N-Ethylaniline as “for industrial use only,” in line with guidelines for hazardous chemical labeling. Packaging standards call for sealed, airtight metal drums or HDPE containers that shield contents from moisture and light. Purity standards for technical-grade product generally call for 99% minimum, listed right on shipping manifests. Impurities, mostly lower alkyl anilines and water, get flagged by GC analysis, and the labeling always includes GHS hazard pictograms, UN codes, and emergency response information. Chemical supply firms know compliance here isn’t just red tape—it’s the frontline defense for shippers, warehouse staff, and downstream users.

Preparation Method

Modern manufacturing often turns to reductive alkylation or alkylation of aniline with diethyl sulfate or ethyl halides. In one classic preparation, aniline reacts with ethyl bromide in the presence of a base like sodium carbonate, splitting off the hydrogen bromide to leave that ethyl group firmly attached to the nitrogen atom. Pilot plants focus on reaction control—keeping temperatures and pressure tight—to boost yield and cut down side products like diethylaniline or unreacted aniline. Chemical engineers often face the headache of byproduct separation here, balancing throughput with the persistent demand for higher purity.

Chemical Reactions & Modifications

N-Ethylaniline keeps many of the reactivity traits of its aniline ancestor. The ethyl substitution slightly deactivates the aromatic ring in electrophilic aromatic substitution reactions but keeps the molecule reactive enough for practical purposes. The compound undergoes acylation to form amides, nitrosation to yield nitroso derivatives, and hydrogenation in severe conditions. I’ve seen it work in lab-scale syntheses as a precursor for more complex aromatic amines, each step picking up tailored groups needed for dyes or agricultural chemicals. Its structure allows derivatization, enabling synthetic chemists to nudge the core amine in directions favored by the pharmaceutical or specialty chemical industry.

Synonyms & Product Names

In trade and literature, you’re just as likely to spot N-ethylbenzenamine or N-ethylanilide as you are N-Ethylaniline. CAS 103-69-5 pops up most frequently in technical documents. So many names for one chemical may sound pedantic, but accuracy in labeling opens the door for traceability in safety audits and customs, limiting ambiguity for buyers juggling dozens of near-identical compounds. Over the years, I’ve watched more than one regulatory recall hinge on missing or mistaken synonyms stamped on a shipment.

Safety & Operational Standards

Anyone who’s handled aromatic amines knows the drill: gloves, goggles, and good ventilation. N-Ethylaniline can irritate the skin and eyes, and inhalation of vapors isn’t something to take lightly. Long-term exposure links to damage in organs and carries possible carcinogenic risk—a reminder that industrial users need to double-check exhaust hoods and keep spill kits close by. Safe storage practices call for cool, dry conditions, away from oxidizing agents or acids. Safety data sheets spell out first-aid steps, firefighting measures, and recommended exposure limits, shaping routines that separate the seasoned professional from the unwary newcomer.

Application Area

N-Ethylaniline’s industrial impact extends across the textile dyeing sector—serving as a precursor for azo dyes—and the rubber processing industry, where it contributes antioxidants that boost tire lifetime. Its antioxidant properties slot neatly into lubricating oil formulations, guarding engines and machines from the slow grind of oxidative breakdown. In the pharmaceutical world, it shows up as a synthon for cardiovascular and CNS drugs. The pigment sector also taps it for ink and toner production. Those sprawling uses explain the chemical’s longevity despite competition from newer, specialized additives.

Research & Development

Academic and industrial labs continue to search for new transformations based on N-Ethylaniline’s amine structure. Modified derivatives bring out possibilities in drug screening and dye innovation. One research trend aims to minimize hazardous byproducts during manufacture, trading toxic reagents for greener options. Researchers probe catalytic pathways that lower reaction temperatures and slash waste production, banking on economic and environmental upside. Access to expanded spectroscopic data, thanks to improved instrumentation, smooths the way for deeper analysis, making it easier to head off contaminants in finished batches.

Toxicity Research

Toxicologists have long scrutinized aromatic amines for the potential to cause cancer or organ damage after repeated exposure. Lab animal studies associate N-Ethylaniline with methemoglobinemia—a condition linked to changes in red blood cells—and chronic dosing points to impacts on the liver and kidneys. Regulatory agencies like the EPA and ECHA flag it as a substance requiring strict workplace controls, and periodic review by occupational health authorities keeps safety information evolving alongside fresh scientific findings. Learning from past industrial incidents, plant operators now build layered protections into routine handling protocols.

Future Prospects

Efforts to improve N-Ethylaniline production now focus on greener chemical pathways and substitution for hazardous reagents. Industry insiders see a demand curve that bends upward whenever rubber processing, dye manufacturing, or specialty pharma expands into new regions. Environmental rules may shape future handling practices, trading traditional solvents for water-based alternatives, and chemical producers already test process intensification methods to shrink the ecological footprint. As research unlocks new applications—especially for customized drug intermediates—suppliers expect more scrutiny but also fresh opportunities to demonstrate the material’s staying power in the competitive chemicals landscape.

More Than Just a Name in a Chemistry Book

N-Ethylaniline doesn’t get splashy headlines, but its fingerprints show up everywhere, especially in industries that touch everyday life. Walk past a car repair shop, browse a pharmacy aisle, or even notice the color in your clothes, and you’ll brush up against uses that trace back to this chemical. Having worked in a laboratory that supplied chemicals to both small businesses and major manufacturers, I’ve watched N-Ethylaniline find a spot on shipping orders stretching from Europe to Asia.

Helping Fuel Move Down the Road

Start with gasoline. Refineries rely on additives to help engines run smoother, last longer, and pass emissions tests. N-Ethylaniline steps up as an antiknock agent. It boosts the octane rating of fuel, so engines resist premature detonation. This small adjustment means cleaner running vehicles and fewer unplanned trips to the mechanic. Cities struggling with dirty air need every bit of help possible, and this chemical lends a hand where leaded additives have faded away.

Stepping into the World of Dyes

Travel into textile production and dye manufacturing, N-Ethylaniline stands out again. Many colorants, particularly those in the blue and green range, begin life as chemical cousins in the aniline family. Through a couple of chemical steps, factories turn N-Ethylaniline into bases for dyes. I’ve seen the difference: without these intermediates, bright, colorfast clothes wouldn’t line store shelves. It’s not just about looks, either—reliable dyes help meet international safety standards on clothing and packaging. Any company sending products overseas figures out pretty fast how valuable these intermediates can be.

Molecules That Save Lives

Ever open the medicine cabinet for something that carries a doctor’s prescription? N-Ethylaniline acts as a starting block in making some pharmaceuticals. Because of its structure, chemists lean on it to create active ingredients for drugs targeting a wide spread of illnesses. I’ve watched colleagues in pharmaceutical labs use N-Ethylaniline to streamline hard-to-solve chemical syntheses. With the cost of medicine already squeezing budgets, finding efficient building blocks shapes what ends up on pharmacy shelves.

Not Just for Factories: Research and Synthesis

Beyond the factory floor, research labs keep N-Ethylaniline on the shelf for more than just academic exercises. It’s handy for producing other complex molecules, serving as a launchpad in developing new polymers, agrochemicals, and specialty chemicals. Unlike some reactants that need careful babying, this compound offers stability and predictability—two things researchers appreciate when chasing after new ideas.

Turn the Page to Responsibility

Widespread use brings up tough questions about health and environmental impacts. In my time working with chemical safety teams, we always circled back to proper handling and disposal. N-Ethylaniline doesn’t belong down the drain or in open air. Companies and labs must follow rules that keep workers and communities safe. Better monitoring, improved storage, and training go a long way. Regulators and watchdog groups have every reason to pay attention as well. Balancing benefits and risks starts with people who know the material inside and out.

What Happens Next?

N-Ethylaniline’s main uses might change over time as technology shifts. There’s talk about greener production methods and safer alternatives. Every year, researchers present new findings on limiting exposure and refining chemical processes. The big takeaway—chemicals like N-Ethylaniline will keep playing roles in industry and science, but everyone involved must keep asking how to use them smarter, safer, and more responsibly.

N-Ethylaniline: More Than Just a Chemical Name

N-Ethylaniline sounds technical enough to be ignored by most people unless they're in the middle of a chemistry class or working in an industrial plant. I once walked through a local plastics workshop with a college friend and saw tanks with intimidating labels. N-Ethylaniline showed up more often than I expected in solvents, dyes, and even some pesticides. It isn't a household name, but it plays a role in the background of daily life — especially in places where manufacturing runs at full steam.

Health Risks That Don't Hide

The problem with N-Ethylaniline starts when people work with it directly. Skin contact can leave folks with rashes or irritation. I read reports from workers in dye factories who mention headaches or feelings of dizziness after a long day near open vats. Breathing in the vapors, especially where ventilation runs short, raises the risk of more serious problems. Research dating back to the 1970s links certain aniline compounds with blood effects, especially a condition called methemoglobinemia, where the blood can't carry oxygen properly. Shortness of breath and fatigue come next.

Allergies develop over time. I talked to a technical supervisor once who couldn’t touch N-Ethylaniline after a year in the role because even a splash on his gloves triggered hives. Safety Data Sheets (SDS) put this compound into the toxic category, based on both acute and chronic exposure results. Even without dramatic accidents, gradual, low-level exposure can add up in workers' bodies.

Environmental Impact: Chemicals Don’t Vanish

N-Ethylaniline doesn’t just threaten people. Runoff from old facilities or accidental spills can lead to contamination in rivers and soil. Bacteria break some of it down, but the compound lingers in water longer than you’d hope. Fish and aquatic insects feel the effects. Some studies from the Environmental Protection Agency (EPA) show reduced movement in small crustaceans after exposure—a red flag since these organisms sit near the base of the food chain. If the chain wobbles, problems ripple upward.

Plants in contaminated soil sometimes show stunted growth. Once pollutants work their way through water or crops, they may reach human hands again—this time through food or drinking water.

Addressing the Problem: No Magic Bullet

Limiting harm starts with paying attention on the factory floor. Good ventilation, proper chemical handling training, and reliable protective gear help keep daily exposure down. I’ve seen places where sensors track air quality and alarms go off if vapors creep above a safe limit. It pays off in fewer sick days and better morale.

For the environment, cleaning up spills right away matters more than fancy innovations. Local communities sometimes organize quick-response teams to tackle runoff before it hits streams. Regulations on storage tanks and waste disposal offer another layer of defense. The European Chemicals Agency classifies N-Ethylaniline as a substance of high concern. This pushes manufacturers to look for safer alternatives or rethink process designs.

Many challenges remain. Change happens slowly in industries built on decades-old habits. Still, taking N-Ethylaniline’s risks seriously saves money, protects people, and helps keep the wider environment healthy for years to come.

What Sets N-Ethylaniline Apart

Ask any seasoned organic chemist about N-Ethylaniline and the response comes quick: C8H11N. This molecule is no showpiece locked away in the world of theoretical chemistry. It finds its roots in dozens of colorants, agricultural chemicals, and as an intermediate for countless reactions. That’s not only because scientists like to tinker with aromatic amines, but because the properties of N-Ethylaniline offer tried-and-true stability alongside reactivity where it matters.

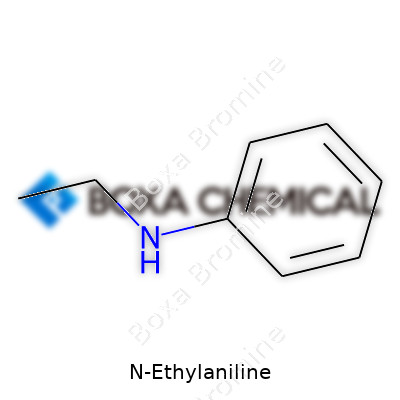

Putting the Pieces Together: Formula and Structure

N-Ethylaniline has a simple formula—C8H11N. At a quick glance, it looks close to aniline. There’s the benzene ring, but instead of a straight-up –NH2 on the ring, one hydrogen is swapped for an ethyl group (–CH2CH3). This tiny tweak changes how the molecule behaves. Draw it out, you’ll see a phenyl group linked to an N, then an ethyl tail. It’s a textbook example of how small changes build a whole new world in organic synthesis.

Seeing the structure in the lab—phenyl ring (six carbon atoms in a hexagon, every other carbon connected by a double bond), attached to an –N(CH2CH3)H group. Shift from aniline (with its straight amino group) unlocks new properties. Researchers value it for the more hydrophobic nature that comes with the ethyl tail, and those extra two carbons play into how it dissolves and reacts.

Where Knowledge and Safety Meet

Working hands-on with N-Ethylaniline, I’ve seen how chemists treat it with respect. It packs a punch—raw exposure causes all kinds of trouble, from skin burns to respiratory irritation. Safety data and rigorous handling protocols exist for good reason. Accidental exposure reminds you fast that a deeper understanding isn’t academic. Practical chemistry means goggles, gloves, fume hoods, and knowing your emergency shower location without hesitation.

Bridging to the Bigger Picture

N-Ethylaniline goes beyond textbooks and industrial process sheets. The importance of knowing the formula and structure isn't just box-ticking for regulatory compliance. Incorrect identification and mishandling have led to serious accidents, as seen in chemical manufacturing history. Risk comes not only from N-Ethylaniline itself, but in how it connects to other compounds—such as dye precursors, or in reactions producing hazardous byproducts.

Many experts urge regular safety audits and transparent safety training, especially in countries ramping up chemical production. Workers using N-Ethylaniline benefit from up-to-date Material Safety Data Sheets (MSDS), and companies employing medical surveillance for those in close contact. Substitution with safer chemicals only works in some roles, so supporting employee education—making sure practical structure knowledge turns into safe habits—delivers a big return.

Lessons Learned from the Lab

Once, in a synthesis demo, mistaken labeling of N-Ethylaniline led to a reaction that wasn’t just a mess, but also a near miss for a serious lab hazard. Double-checking both structure and formula stopped things before they escalated. Small oversights flip quickly into big problems.

The details make all the difference. Recognizing structural distinctions like those between N-Ethylaniline and similar amines translates to safe, successful chemical work. From hands-on experience to global guidelines, paying attention to exact structure and formula keeps standards high and people safe. That’s knowledge worth passing along.

N-Ethylaniline in Everyday Industry

N-Ethylaniline carries a reputation in labs and factories. This chemical finds its way into dyes, pharmaceuticals, and rubber products. Its widespread use means almost every workplace has to put some thought into how it’s stored and handled. Like many organic chemicals, N-Ethylaniline brings its own set of risks. Health and safety teams keep a close eye on it, not just to tick boxes, but to protect people who work with it every day.

Storing N-Ethylaniline Safely

No one wants to deal with a chemical spill. N-Ethylaniline asks for real care. Storing it in a cool, well-ventilated spot keeps problems far away. Direct sunlight invites both temperature changes and potential chemical breakdown. Metal drums with tight-sealing lids or glass containers resist leaks and block fumes. Flammable cabinets may cost extra, but the investment pays off by lowering the fire risk. I’ve seen busy warehouses where a minor lapse in proper storage led to headaches, cleanup, and, worse, health scares. Taking shortcuts costs more in the long run.

Avoiding contact with strong oxidizers and acids is just as important as keeping the chemical away from flames. The reactions can turn vicious and fast. Separate storage areas and clear labeling cut down on mistakes. It’s easy to forget about a single misplaced bottle until someone notices a strange smell or, worse, a hiss from a drum. No one wants that story to belong to their workplace.

Handling: More Than Just Common Sense

Anyone working with N-Ethylaniline deserves clear training on its hazards. Splashing it on your skin doesn’t just cause irritation—long-term exposure brings headaches, dizziness, and worse if inhaled or absorbed. Proper gear makes a big difference. Wearing nitrile gloves, chemical splash goggles, and a simple lab coat offers a reliable barrier. In spaces where ventilation can’t keep fumes away, respirators block inhalation risks.

Small spills can happen in even the most organized labs. Absorbent pads and well-labeled neutralizing agents save a lot of trouble. Well-practiced teams jump to action without scrambling. I've cleaned small chemical spills myself, and clear, step-by-step guides always help everyone work fast and safely. Good managers keep eye-wash stations and emergency showers ready—it all comes down to being prepared instead of lucky.

Why Policy and Planning Matter

Reliance on instructions alone rarely cuts it. A culture of safety makes a real difference. Management that walks the talk, checks in with workers, and maintains storage areas sets the tone for everyone. New workers catch the message fast: take it seriously or risk a fine, or far worse, an injury. Regular training keeps lessons fresh and reduces costly slip-ups.

Government agencies, such as OSHA and relevant local bodies, issue regulations for a reason. Studies collected by the National Institutes of Health and others show occupational exposure links to health problems—so their guidelines reflect real-world incidents, not just theory. Adopting up-to-date Material Safety Data Sheets and reviewing protocols brings the mix of science and practicality that people trust.

Securing a Safer Workplace

N-Ethylaniline doesn’t forgive carelessness. Good storage and handling shape more than compliance—they protect skilled, hardworking professionals. Everyone from chemists to warehouse staff deserves a workspace that respects both their health and their time. Investment in the basics—sensible storage, strong policies, straightforward training—builds trust and safety from the ground up.

A Closer Look at Its Basic Traits

N-Ethylaniline stands out for its simple structure, yet the differences in its physical properties matter more than many folks realize. The pure compound forms a clear, slightly yellow liquid at room temperature. This appearance might fool some into thinking it behaves much like water, but it brings a different set of characteristics to the table.

Melting and Boiling Point

A key fact: N-Ethylaniline does not freeze easily in a standard freezer. The melting point stays low, checking in at roughly -70°C. That means it keeps a liquid form even in temperatures far colder than most labs experience. There’s practicality in this for chemical storage and use; no clumps or solid formation make it easier to handle outside extreme conditions.

The boiling point tells a different story. N-Ethylaniline starts boiling at about 216°C. That’s much higher than water, which makes evaporation slower and open pours less risky in regular environments. This feature allows for simple separation and distillation steps during chemical processing. Any researcher heating the liquid can trust its stability over a good temperature range. It doesn’t vaporize quickly, so spills in a warm lab are unlikely to fill the air with fumes as fast as more volatile substances.

Other Physical Details

This compound doesn’t just skate by on melting and boiling points. Its density at room temperature holds at about 0.95 grams per cubic centimeter. In my experience handling small batches, the low density makes it manageable with glass pipettes—no sluggish movement, not much residue left behind.

There’s also a weak amine odor, common for this chemical group. Many folks in the lab still remember their first whiff: the scent isn’t harsh, but it’s noticeable. It helps you keep tabs on accidental spills, so nobody loses track of where N-Ethylaniline goes. Lab safety matters, especially with compounds you do not want on your skin long-term.

Why These Numbers Count

If you work with N-Ethylaniline, understanding its melting and boiling points gives you a clear edge. Low melting point means you don’t have to fuss with pre-warming the bottle or dealing with broken solids. High boiling point lets experiments run at higher heat without worrying about dangerous vapor buildup.

I’ve seen setups where students tried using glassware designed for lighter solvents. They soon learned the hard way: if you run N-Ethylaniline through a common condenser tuned for water or ethanol, the slower evaporation means less product loss and more control over the reaction’s pace.

Safer Use and Future Practice

Spreading knowledge about these physical properties keeps everyone safer. Clear labelling, good airflow, and proper handling methods cut back on accidents. People pay closer attention after learning why this clear liquid doesn’t behave like the water it resembles.

In production, these properties guide how companies store N-Ethylaniline. Large drums don’t need chillers and can stand up to changes in room temperature without risk of rupturing or leaks. For research, knowing the boiling point helps decide heating choices—and makes it easier to stick with protocols.

Melting and boiling points give us more than numbers. They show us how to treat a substance, shape lab routines, and make better choices for both safety and productivity. Every property shapes decisions, from the bench in a teaching lab to the warehouse floor.