Methyl Chloroacetate: A Deep Dive into Its History, Science, and Role in Industry

Historical Development

Looking back to the early twentieth century, folks in chemical labs discovered methyl chloroacetate as they experimented with simple acid and alcohol reactions. The rise of the textile and pharmaceutical markets kept driving chemists to pinpoint intermediates that worked fast in synthesis. Methyl chloroacetate set itself apart due to its strong reactivity and ability to bridge carbon chains in bigger molecules. During the golden decades of industrial chemistry, production moved from flask-scale curiosity to reactors humming day and night. By the seventies, safer processes let larger outfits refine the process, pushing the compound into mainstream production. The pathway, shaped by trial, error, and gritty lab work, blends classic organic chemistry with steady factory grit.

Product Overview

Methyl chloroacetate plays a crucial part in synthesizing drugs, herbicides, and dyes. This chemical acts as a building block, helping chemists put together complex frameworks quickly. Its sharp, pungent smell gives it away in the lab. It is a clear, colorless liquid—a small bottle goes a long way for skilled teams. Despite its popularity, folks need to stay sharp when handling it, as a splash or a whiff can have lasting effects. Those who rely on precision in plant labs know methyl chloroacetate as an asset, not a casual bench supply.

Physical and Chemical Properties

This liquid boils at just over 106°C, giving off fumes that fill a room in seconds. It mixes with alcohol, ether, and many organic solvents, letting chemists blend it smoothly in reactions. Its density sits near 1.20 g/cm³ at room temperature. Surface tension pairs with a keen chemical bite—the carbon-chlorine bond is ready to react, tearing into bases and nucleophiles or splitting apart under alkaline conditions. The methyl ester makes it more reactive than unmodified acid or salts, cutting reaction times in the right setup. Those attributes draw both opportunity and risk to anyone planning work with it.

Technical Specifications & Labeling

In most labs and plants, methyl chloroacetate comes labeled with hazard symbols warning of both its toxicity and environmental danger. Purity usually reaches 98% or higher, which means handling calls for proper gloves, goggles, and forced air in the work area. Labels call out “flammable” and “harmful if inhaled or swallowed,” along with UN codes for shipping and storage. Production batches get tracked for trace impurities—halogenated solvents, free acid, and water, which can tip off bigger problems if quality slides. Certified reference material, with all paperwork checked off, gives buyers confidence and regulators peace of mind.

Preparation Method

Large-volume makers use a direct route: treat monochloroacetic acid with methanol, usually with an acid catalyst like sulfuric acid. After refluxing and washing away acid, distillation brings the product up to snuff. In small jars, a careful drip and constant stirring keep runaway heat in check. Industrial setups run these steps under closed systems, with slick condenser units catching vapors for recycling. Each batch may show differences if the water balance tips or the acid isn't pure, so steady monitoring isn’t optional.

Chemical Reactions & Modifications

In synthesis plans, the active chlorine and ester blend gives methyl chloroacetate a dual identity. Chemists use the chlorine for nucleophilic substitution, swapping it out to install new side groups. In other hands, the methyl ester offers transesterification or hydrolysis, letting teams shape new carboxylic acids on demand. Makers of medicines or crop protectants grab this compound to anchor functional groups, pump up molecular weight, or fit specific bioactive frameworks. You see it pop up in schemes for drug building blocks, insecticides, and even in materials science for surface coatings.

Synonyms and Product Names

The label may say “chloracetic acid, methyl ester,” “chloroacetic acid methyl ester,” or just “MCA.” In catalogues, product codes change, but the compound’s sharp odor and fast reactivity cut through the jargon. Different firms brand it for R&D, flavors, or industry, though it’s the same backbone molecule. Some agencies use the IUPAC name, others prefer trade names intended for bulk sales. Knowing them all keeps confusion at bay when moving from bench chemistry to warehouse pallets.

Safety & Operational Standards

Every gram of methyl chloroacetate comes with a set of safety paperwork longer than most novels. Splashing a drop can burn skin, and vapor exposure will irritate eyes, lungs, and, after enough contact, the central nervous system. Workers stand inside fume hoods, wearing long gloves and goggles. Storage stays in cool, aired-out cabinets far from heat or open flames; the compound will catch fire with a spark. Air monitoring and regular first-aid drills go hand-in-hand with day-to-day work in production plants. Emergency showers, absorbent pads, and neutralizing agents remain close to every operating line.

Application Area

Pharmaceutical companies count on this reagent for pain killers, antibiotics, and cardiovascular medicines. Agrochemical firms build it into weedkillers and pest control mixes. Textile manufacturing teams trace it in certain dye syntheses, and research labs use it for tailoring molecular probes or as an intermediate for other key reagents. Any spot where synthesis needs fine control over chain length, branching, or selective reactivity, methyl chloroacetate steps in. It’s not a specialty compound, but a workhorse crossing the boundaries from research benches to massive reactors.

Research & Development

Teams in academic and industrial labs look for new reaction conditions to tame methyl chloroacetate’s volatility while expanding its reach into greener chemistry. Some groups target process improvements: less acid, fewer byproducts, easier solvent recovery. Others measure how different nucleophiles sharpen selectivity or lower costs for downstream drugs and polymers. Global research pays close attention to energy balance in production, accident rates, and how waste streams impact local environments. Every improvement tweaks yield, safety, or utility for the next generation of users. My own time spent running pilot-scale reactions with methyl chloroacetate hammered home how a few smart changes can cut costs, lessen waste, and make routines safer for operators coming in on a night shift.

Toxicity Research

Methyl chloroacetate’s risk to human health can’t be underplayed. Inhaled vapors irritate the upper respiratory tract, and chronic exposure carries risk for headaches, nausea, and nervous system effects. Studies in rodents show organ toxicity after repeated doses. Skin tests flag it as a definite irritant, with enough potency to demand high standards for gloves, masks, and clothing. Labs testing for biodegradability point to slow breakdown in water and soil—meaning accidental spills linger unless properly remediated. Waste handling must meet strict standards, or the chemical will work its way into drinking water and affect nearby communities. Expert toxicologists keep re-examining the thresholds for safe air and surface levels, always updating guidelines as new data comes in.

Future Prospects

The road ahead for methyl chloroacetate looks to improved safety, lower waste, and sharper targeting in distribution. Chemists developing new medicine or crop protection recipes see its dual reactivity as a strong advantage for rapid molecular assembly. Markets for green chemistry and sustainable production lead companies to seek ways to recycle solvents and fully close the loop on process waste. Digital monitoring and automated reaction controls cut down the risk from operator error. Ongoing innovation uncovers safer catalysts and milder conditions, opening the door for small-batch and even home-scale production setups with stronger oversight. The balance between utility, cost, and safety keeps this chemical in the toolkit—so long as everyone stays alert both to its hazards and to the ever-changing landscape of regulation and market demand.

A Chemical With Many Jobs

Some chemicals never end up famous, but their work touches every day. Methyl chloroacetate fits into that category. A colorless liquid with a sharp smell, it shows up quietly in a range of industries. The story gets interesting when you start digging into what gets made with it and why modern manufacturers keep it around.

Building Block in Manufacturing

Methyl chloroacetate serves as a building block. The chemical industry uses it as a starting point when making more specialized compounds. It helps form medicines, dyes, pesticides, and even plastics. That’s because it reacts easily with other substances, kicking off important transformations in the lab and factory.

Pesticide Ingredients

Methyl chloroacetate doesn’t go into the soil by itself—far from it—but it does help create other chemicals that end up in the field. Farmers rely on several pesticides that keep insects or weeds at bay, and making those pesticides sometimes begins with methyl chloroacetate. Take herbicides like glyphosate or insecticides like carbaryl; both have had ties to this chemical during early production steps. Its reactivity becomes an asset when designing molecules meant to target pests while sparing crops.

Pharmaceutical Synthesis

Medicines often demand precise chemistry, and methyl chloroacetate stands out as a tool for that job. In the lab, people use it for making compounds that go into drugs for fighting bacteria or treating certain types of cancer. For example, the chemical helps introduce special groups into molecules, unlocking reactions that lead to important medicines. Drug makers value its ability to open doors that few other chemicals can, especially during the tricky middle steps of synthesis.

Use in the Dye Industry

Clothing, screen printing, and even inks for pens occasionally involve traces of methyl chloroacetate—at least early in the process. Before a shirt gets its color, a dye must be designed. The chemical backbone of certain dyes includes pieces crafted with methyl chloroacetate. Its role usually fades away before the product arrives in stores, but the color that people enjoy often owes a debt to this unassuming liquid.

Safety and Environmental Side

This chemical carries risks. Methyl chloroacetate can irritate the skin, eyes, and lungs if handled carelessly. Companies keep a tight lid on tanks and pipes, and workers wear gloves and protective gear. Environmental rules treat it seriously because runoff or accidental release can harm living things in water or soil.

That makes responsible storage and transport critical. Facilities use sealed systems and scrubbers to limit leaks. Workers need clear, regular training. Companies look to greener methods—a step up from older ways that wasted more material or led to bigger spills.

Looking for Better Alternatives

Many chemists today ask if it’s possible to switch to safer chemicals or even renewable sources. They search for methods where methyl chloroacetate wouldn’t be needed or could be swapped with something less risky. Some success has come from tweaking recipes or developing new catalysts. Every bit of progress protects communities and workers, and encourages a culture of safety in the industry.

Takeaway

Methyl chloroacetate proves how much chemistry supports daily life, often behind the curtain. Its story shows the value in careful handling, creative problem-solving, and never taking shortcuts with health or safety. People can push industries to keep improving, and maybe tomorrow, the next safer method will take its place.

Why Handling This Stuff Takes Respect

Methyl chloroacetate can be a nasty customer if you get careless. Anyone who’s spent time around a chemical plant or lab remembers the smell: sharp, almost sweet, and unmistakable. You quickly figure out that ignoring proper practices invites trouble. Breathing in its vapors or splashing it on skin can leave a mark that lingers much longer than you’d like. Regulators don’t throw rules around for no reason here. Health and safety folks sound the alarm on methyl chloroacetate due to its toxic nature. Exposure can inflame the eyes, damage the lungs, or irritate skin. In severe cases, it can impair the nervous system or even prove fatal. Taking shortcuts isn’t an option.

Real Safety Gear Makes the Difference

People talk about personal protective equipment all the time. With this compound, it’s not a formality. Good lab coats, chemical-resistant gloves, splash-proof goggles, and proper respirators block danger before it starts. Just grabbing a dust mask or thin latex gloves from a first-aid kit won't cut it. Anyone who’s had glove material eaten through by solvents learns this lesson fast.

It’s about choosing gloves made of nitrile or Viton, not something that melts away. Respirators should use organic vapor cartridges, as cheap paper masks let toxic fumes through. Eye protection must wrap fully, since even tiny drops hurt. This gear might slow you down, especially in a hot warehouse, but the peace of mind outweighs a little sweat.

Handling and Storage: Tight Controls, Zero Guesswork

Safe storage runs deeper than tossing bottles on a shelf. Methyl chloroacetate belongs in a cool, dry, locked cabinet with solid ventilation. Those old amber bottles do more than just look pretty. Light and heat can set off reactions. It pays to separate it from strong bases, amines, and oxidizers. A spilled bottle mixing with the wrong chemical makes for an emergency call nobody wants. Tightly sealing containers and labeling with clear warnings keeps surprise leaks or misuse at bay.

Fume hoods are a must. A few minutes of work under open air and you risk headaches or coughing fits. Fan systems baffling away vapors save your lungs and everyone else’s down the hall. Spill kits—overflow absorbents, neutralizers, cleanup gear—should stay within reach. No one wants to hunt for supplies during a crisis.

Training and Smart Planning

No one walks in knowing everything. Solid training, both hands-on and written, sharpens instincts. Watching a seasoned tech react to a minor spill beats a PowerPoint any day. Emergency showers and eyewash stations matter when something goes wrong. In my own experience, drills make the difference. Walking through fast evacuation routes and knowing emergency numbers by heart saves precious seconds when things go sideways.

Reporting and Tackling Accidents Without Delay

If an exposure happens, don’t tough it out. Wash skin right away, rinse eyes for a full 15 minutes, and get medical help. Reporting near misses helps the whole team shape better habits. Feedback after close calls can stop the next accident. Storage and use logs keep track of every drop, cutting down on “where did that bottle go?” moments.

Methyl chloroacetate isn’t something to fear, but it definitely deserves respect. Real-world attention to PPE, storage, and training goes a long way. The goal stays simple: handle it right, go home healthy, and keep your coworkers out of trouble. That’s a win every day.

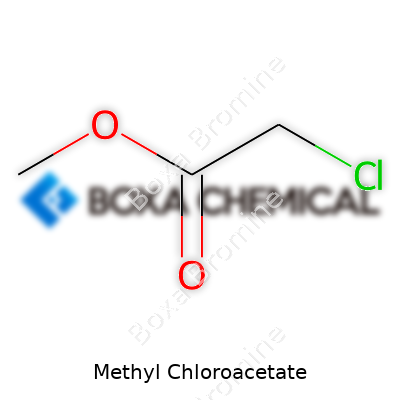

Breaking Down the Chemical Formula

Methyl chloroacetate has the formula C3H5ClO2. That’s the concise answer you’ll find in any chemistry reference. Three carbon atoms, five hydrogens, one chlorine, two oxygens—on paper, it feels straightforward. Out in the lab or the factory, it carries a lot more weight.

What This Compound Is Really About

This isn’t just another random molecule. Methyl chloroacetate stands out because it shows what can happen when you start tinkering with simple building blocks. Add a methyl group to chloroacetic acid: you get a liquid with a pretty strong, almost pungent smell. In my college days, I remember handling this in advanced organic chemistry labs, always wearing gloves because the skin absorbs it, and trust me, even small spills sting.

I’ve watched professional labs use it as a tool—a starting point for making all sorts of chemicals. For example, technical guides mention its use in producing herbicides, pharmaceuticals, dyes, and certain plastics. That single chlorine atom turns it into a reactive agent, perfect for chemical synthesis. The process usually starts with monochloroacetic acid, which reacts with methanol in the presence of an acid catalyst.

Getting to the Heart of Safety

What sticks with me whenever I see methyl chloroacetate isn’t the elegance of its formula, it’s the reminder that the smallest molecules can lead to big dangers. This one absorbs quickly through the skin and can damage the nervous system, kidneys, and lungs in a poorly ventilated space. Safety data sheets classify it as highly toxic; regular gloves won’t always do the trick, so you go for butyl rubber. Facilities handling it need robust ventilation, chemical fume hoods, spill kits, and people trained for emergencies.

One fact stands out: between 2010 and 2020, a few industrial accidents from careless handling of this chemical ended with hospital visits. Reading those reports reinforces why a simple change in molecular structure can turn a harmless-looking liquid into a real threat.

Practical Uses and Experience

Chatting with environmental engineers over the years, I’ve heard concerns about mishandling and runoff. Methyl chloroacetate degrades in soil over weeks, but its toxicity to aquatic organisms means accidental spills near waterways could wipe out fish populations fast. Chemists pushing for greener methods now look into recycling solvents, using flow reactors to minimize exposure, or swapping out methyl chloroacetate for less hazardous options, but the substance remains a staple for certain syntheses.

Building Safer Chemistry Knowledge

Learning formulas in class feels simple; understanding their real-world impact takes more time. Whether preparing a pharmaceutical or tweaking a pesticide formula, chemists need to balance usefulness and safety. Experience, not just a textbook, teaches respect for chemicals like methyl chloroacetate. The formula C3H5ClO2 won’t ever remind you to check your gloves or open the windows. Only practice will do that.

Why Proper Storage Matters

Nobody in a lab or an industrial plant sets out to make their day harder, but skipping careful chemical storage often ends up that way. Methyl chloroacetate can catch people off guard. It looks innocent, but it’s known to irritate skin, eyes, and lungs. If the container fails or leaks, the vapors travel. Suddenly, a single mistake means an emergency, not just a cleanup.

Personal experience with chemical handling has taught me that normal routines go out the window during an emergency. In my first real laboratory job, I saw a small bottle leak on a shelf nobody checked often. The fumes damaged wires and labels, and a coworker got a bad rash. The company had to evacuate. Had we paid more attention to details in storage—strong containers, clear labeling, airtight seals—we would have saved hours and a lot of stress.

Conditions and Containers: Don’t Cut Corners

Methyl chloroacetate reacts with water and releases hydrochloric acid, so leaving it exposed to humid air invites trouble. Strong, high-quality glass or metal containers usually do the trick. I always argue for thick-walled, chemical-resistant bottles, with secure caps that hold up under pressure. Keeping the container tightly sealed after every use turns this from a hazard into another harmless item on the shelf.

Ask any chemical safety expert to open their notebook, and you’ll find a section on flammable and reactive liquids. Methyl chloroacetate belongs in a cool, well-ventilated storage room away from heat sources. I once watched a warehouse manager ignore this advice to save space. A small fire started on the next shelf, and, because of flammable vapors, a minor accident almost turned much worse. The lesson: storing far from anything hot or prone to spark isn’t optional, it’s essential.

Labeling: A Simple Detail That Can Save Lives

Professional labels seem like pointless bureaucracy until something happens. If there’s an emergency and the responders know what’s in the leaking bottle, the response will be fast and right. I always include the chemical name, hazard symbols, and a recent receipt date on every bottle. It’s easy to forget what a faded or handwritten note means; that won’t happen with a printed, dated label.

Accurate inventory limits old stock from sitting too long in storage. Some places rotate chemicals, others dispose of unused or expired supplies. Checking dates isn’t about fussing—it protects everyone who shares that space.

Design Safe Workspaces

Keeping methyl chloroacetate in a well-ventilated area with spill trays underneath makes cleanup easier if something leaks. All my former workplaces use metal or plastic spill containment trays on every storage shelf, not just for spills but to prevent small leaks from seeping onto other surfaces. Safety showers and eyewash stations always make a difference in places where hazardous liquids like this one are in use. People react faster if they know help is just a step away.

It’s Not Just About Rules—It’s About People

Following these best practices comes from experience—not just regulatory compliance. The smallest shortcut around safety often leads to the worst stories. Asking for advice from people with hands-on time around these chemicals brings out details rules can miss, like checking seals after each use or double-bagging containers for transport. Ultimately, it’s the discipline of careful storage that protects everyone.

Taking a Closer Look at a Chemical Lurking in Industry

Methyl chloroacetate isn’t something most folks talk about over breakfast. But if you’ve worked anywhere near laboratories, manufacturing, or chemical storage, you know it carries a reputation that’s hard to ignore. Used to make dyes, pharmaceuticals, and various pesticides, the stuff rarely comes up in everyday conversation unless trouble starts. Once you dig into the details, some troubling facts rise to the surface.

The Real World Impact of Exposure

Chemical exposure has a way of cutting past theory—people notice right away when their eyes start to water or a cough sets in. When workers inhale methyl chloroacetate, irritation hits eyes, throats, and airways fast. Persistent contact causes skin to burn, sometimes blister, and leaves a mark that lingers long after the spill has been cleaned up. If safety gear fails or isn’t worn, absorption through the skin brings its own risks: headaches, nausea, dizziness, and confusion sometimes arrive with little warning. This information isn't just hearsay from manufacturing floors. It's from workplace incident records and published toxicology reports.

Taking a trip through the US National Library of Medicine, you find studies describing serious central nervous system effects in those accidentally exposed. Severe poisoning leads to convulsions and, at worst, respiratory paralysis. These outcomes aren’t common in controlled settings, but lapses in training or handling send workers to emergency rooms every year. Trouble often starts with a single missed step—rushing to transfer a batch, skipping a glove, mislabeling a drum.

What Science Tells Us About Safety

Methyl chloroacetate breaks down inside the body into chloroacetic acid, which brings even more serious risks if not flushed out quickly. Medical researchers point out long-term dangers: chronic exposure might link to nervous system symptoms or even liver and kidney damage. Reports collected by the CDC and OSHA make it clear—people underestimate this chemical because it smells slightly sweet. That pleasant trace doesn’t mean it’s safe. Too many scents in chemistry hide a real sting.

Protecting People in Industrial Settings

Relying on proper handling and storage makes all the difference. Those who work with methyl chloroacetate need the basics nailed down—chemical-resistant gloves, eye protection, solid ventilation, and reliable spill containment. These aren’t fancy solutions but they come straight from hard-earned experience. The American Conference of Governmental Industrial Hygienists sets low exposure limits for a reason. No amount of protective gear works without real training. Newcomers and veteran workers both need refreshers: which label matches which bottle, how to use emergency showers, what the alarm sounds like.

Inspection routines should go beyond the checklist. If piping corrodes or seals start leaking, trusting a maintenance log over a real look puts everyone at risk. Companies ought to invest in high-quality detection systems, even if the initial cost stings. Fast identification of leaks beats the fallout from hospital bills or shutdown orders.

A Shared Responsibility for Health

There’s a tendency to brush off chemical risk until someone gets hurt, especially in places trying to hit production targets or cut corners. Truth is, protecting the health of workers, neighbors, and the environment makes ethical sense and keeps businesses out of expensive trouble. Transparency in reporting spills, quick access to treatment information, and honest assessment of workplace hazards play a role bigger than compliance. Trust grows in teams where everyone knows that the people in charge actually care about their well-being.