Hexachlorobutadiene: Not Just Another Chemical

Historical Development

Hexachlorobutadiene (HCBD) didn’t start off as a household name. Early records date back to experimentation in the mid-twentieth century, mostly as a byproduct during the production of chlorinated solvents such as tetrachloroethylene and trichloroethylene. Chemical manufacturers found HCBD in the waste streams and, for years, it collected in the underbelly of the industry. Over time, industrial chemists began to realize its unique structure carried both promise and risk. The first surge of attention came from its stability and high density, capturing interest from those searching for better ways to control industrial processes or manage persistent contaminants. As more attention focused on environmental safety, researchers took another look, spurred by concerns over its long-term ecological impact.

Product Overview

HCBD shows up as a colorless to pale yellow liquid, recognizable by its mildly sweet, chloroform-like odor. It rarely serves as a main product; most of the time, it appears as a secondary compound, especially during the large-scale chlorination of hydrocarbons. Some chemical producers, recognizing unique physical traits, harvest HCBD for its solvent properties or its role in creating specialty chemicals. Use remains restricted in many regions due to environmental and health risks, driving a need for strict oversight.

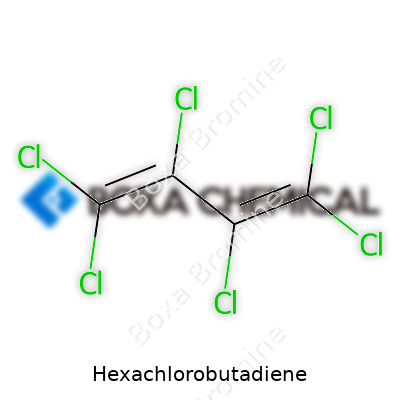

Physical & Chemical Properties

HCBD holds a molecular formula of C4Cl6, sporting six chlorine atoms bonded to a four-carbon backbone. Expect a high boiling point, close to 215°C, and a density above 1.6 grams per cubic centimeter; its vapor pressure runs low. It does not dissolve in water easily but finds quick solubility in organic solvents. Its stability often baffles casual handlers; this chemical resists thermal breakdown up to substantial temperatures. Sunlight and strong oxidizers can bring on slow decomposition, and if it burns, the fire produces hydrogen chloride and phosgene, both dangerous gases. This makes storage and handling more critical.

Technical Specifications & Labeling

Facilities storing HCBD label drums or tanks with hazard symbols that reflect toxicity and environmental threat. Packaging tends to stick to steel drums with secure seals, minimizing vapor leaks. Safety data sheets note the need for chemical-resistant gloves, goggles, and splash-proof clothing. Specific standards, such as those set by the European Chemical Agency or the US EPA, direct volume limits and permissible exposure levels. Tracking batch numbers and source documentation became standard practice once companies realized HCBD contamination followed supply chains all the way to small-scale recyclers and refineries.

Preparation Method

Chlorination reactions drive most production, where hexachlorobutadiene surfaces as a byproduct. Usually, large-scale plants react butadiene or butane with chlorine gas at elevated temperatures. Secondary treatments such as distillation separate HCBD from more volatile substances. Some processes start with tetrachloroethylene, treating it with chlorine in the presence of catalysts to coax out higher-chlorinated organics. Every major synthesis path underscores the risk of accidental releases, leading engineers to design ever more sealed reactors and efficient scrubbers.

Chemical Reactions & Modifications

Hexachlorobutadiene does not react easily with bases or mild acids, but reducing agents can strip away chlorine atoms, producing less chlorinated compounds or sometimes forming unsaturated products. Chemists have dabbled with catalytic hydrogenation, aiming to produce intermediates for agrochemicals. Radical reactions with heat and strong UV can break down the structure, but this tendency also introduces toxic byproducts. One memorable research shift saw interest pivot toward HCBD’s use as a chlorine donor in organic synthesis, supporting transformations where safer, less persistent options failed to deliver.

Synonyms & Product Names

On labels or in critical papers, HCBD may go by several names: perchlorobutadiene, hexachloro-1,3-butadiene, hexachloro-2-buta-1,3-diene, or simply by an assigned code such as UN 2279. These synonyms trace back to different international regulatory catalogs, each trying to bring some order to a chemical with a checkered history. Other terms, like “Solvent 465,” may appear in archived manufacturing manuals, a reminder of its once greater industrial reach.

Safety & Operational Standards

Up-to-date training alone safeguards workers from HCBD’s dangers. Leaks, spills, or casual exposure risk skin blisters or respiratory issues; the vapor easily irritates eyes and lungs. Facilities need forced-air ventilation, chemical fume hoods, and spill kits on hand. Inhalation over time threatens liver and kidney damage, so employers monitor indoor air often; most agencies put exposure limits at one part per million. Emergency plans stand ready, including eye-wash stations and oxygen masks. Storage facilities separate HCBD from acids, metals, and heat sources, since careless mixing ramps up hazard potential.

Application Area

At one time, people found uses for hexachlorobutadiene as a solvent for rubber and other chlorinated organics. This function faded, partly because equally effective substitutes arrived and partly because environmental rules clamped down. Agricultural research once tried using it as a nematocide, injected below the soil to kill root-destroying worms. Concerns over persistence in water and soil ended this approach in many places. Research labs sometimes rely on HCBD as a chemical intermediate, though small quantities suffice. No one can ignore its role in controlling fires in magnesium processing, where HCBD’s stability lets it blanket burning metal and starve the blaze of oxygen.

Research & Development

Much recent research centers on minimizing HCBD’s environmental footprint. Scientists monitor soil and groundwater samples from manufacturing hotspots, analyzing residue patterns years after plants shut down. Ongoing improvement continues in the quest for safer manufacturing methods or better destruction technologies, like supercritical water oxidation or plasma incineration. Compliance professionals cross-check laboratory findings against regulatory thresholds, while toxicologists seek biomarkers that signal early exposure. Across the globe, experts gather for roundtable reviews, comparing recovery and remediation data from different continents.

Toxicity Research

Toxicity remains a sticking point with HCBD. Animal studies show it builds up in fat, moving through food chains until it reaches predatory species. Lab experiments on rodents exposed to vapor or contaminated feed turned up signs of liver, kidney, and nervous system damage, pushing agencies to develop risk assessments. Monitoring programs in industrial zones try to track long-term exposure among workers and nearby residents. Debates continue about safe levels; some argue the old standards didn’t factor in new findings from chronic studies. Cleanup planners weigh technology versus time, often forced to accept “containment” solutions for decades.

Future Prospects

The future for hexachlorobutadiene centers less on new uses and more on how to handle the leftovers from its complicated past. Policy makers revisit disposal standards, hoping advances in treatment can shrink toxic stockpiles. Some chemists propose breaking down HCBD into less harmful fragments using bioremediation or next-generation catalysts. Regulatory agencies update tracking lists to include smaller-scale recyclers, making sure that even tiny leaks show up on industry radar. Most innovation takes shape in solving old problems: detection, safe handling, and cleaning up legacies from mid-century industry. Stakeholders from government, business, and science meet to compare ideas, reminding everyone why vigilance never goes out of style.

Old Chemicals Still Linger

Most people haven’t heard of hexachlorobutadiene, but it deserves some attention. It’s one of those chemicals from the era when industries ramped up production and tried out compounds that seemed promising for a range of jobs. My interest in chemical safety sparked after hearing stories from workers who remembered the days before gloves and goggles were standard. The way they talk about these chemicals reveals real risks and the long shadows they cast.

Where Does It Show Up?

Hexachlorobutadiene has been used mainly in making rubber compounds. In the lab, it’s worked as a solvent because of its strong knack for dissolving other substances. Old industrial processes relied on it for cleaning and to extract valuable compounds, like chlorine, in making aluminum or magnesium.

Some people might remember the days of carbon tetrachloride in dry cleaning—it’s a similar story here. Hexachlorobutadiene worked because it could break things down where milder solvents failed. That power came at a price, and health agencies like the EPA and the World Health Organization don’t want it lingering around people or wildlife.

Health Concerns and Environmental Impact

Materials such as hexachlorobutadiene stick around and don’t break down easily. This means they travel in water, soil, and air farther than anyone intended. Studies over the past decades found that even small exposures can damage kidneys and the liver. High doses gave lab animals worrying cancer rates. The International Agency for Research on Cancer classifies it as possibly carcinogenic.

People in towns near chemical plants or old industrial sites sometimes find residues in groundwater or soil. I saw this first hand while working with environmental groups in the Midwest. We sampled well water for persistent pollutants, and hexachlorobutadiene showed up on the list of concerns. Regulations don’t just come from nowhere; they follow evidence that a compound sticks around in bodies and neighborhoods far too long.

The Push to Eliminate Legacy Chemicals

Banning the direct use of hexachlorobutadiene in many countries didn’t fully solve the problem. The compound still forms as an unwanted byproduct during production of other chlorine-based chemicals. Facilities that once poured it into holding ponds now need plans to catch and destroy it safely. That costs money and time, but the result is fewer people wind up exposed.

People sometimes ask why it takes so long to clean up these sites. The short answer is that the pollution spread out over decades. There are no shortcuts in tracking it down and removing it. Cleanup teams dig up contaminated soil, pump out groundwater, and incinerate the waste at high heat. These cleanups can drag on for years.

What’s Next: Responsibility and Safer Alternatives

Industry now looks for safer ways to produce the compounds we rely on every day. Processes that once relied on hexachlorobutadiene have shifted to less toxic alternatives. Consumers drive some of this change by asking about the chemicals involved in everything from plastics to cleaning products.

My own experience tells me real progress happens when ordinary people ask questions and demand safer choices from companies and regulators. History shows us that unchecked chemical use creates big problems that someone, someday, will have to clean up. Continued investment in research, transparency, and safer chemistry pays off for both public health and the planet.

Understanding What Hexachlorobutadiene Is

Hexachlorobutadiene, or HCBD, isn’t something most people come across in daily life. This chemical usually turns up in industrial settings, especially where chlorinated solvents are made or used. Think factories handling rubber compounds or making certain pesticides—those are the sorts of places traces of HCBD get released into the air or water. I’ve spent time near industrial zones and, even with heavy regulations, weird smells sometimes drift across neighborhoods. Many times, what you can’t see or smell can do the most harm.

Why Exposure Brings Risks

HCBD has caught the attention of toxicologists. Repeated studies on lab animals show it doesn’t play nice with the liver and kidneys. People exposed through their jobs—breathing, touching, or swallowing contaminated particles—run a real risk. If you look at health reports, the chemical links up with symptoms like nausea, headache, and in higher doses, damage to vital organs. The science is solid: IARC, the World Health Organization’s cancer agency, tags HCBD as a possible carcinogen. That means enough evidence exists to raise alarm, even if nobody can slap down a certain number for “how much is too much.”

Where Problems Show Up

Factories that process chlorinated chemicals can accidentally leak HCBD into groundwater. Public health records in regions near outdated chemical plants reveal higher-than-average kidney issues, plus higher cancer risks. Those aren’t coincidences. Regulations have closed a lot of loopholes in Western countries, but some waste still ends up in rivers and soil elsewhere. Once it gets there, hexachlorobutadiene sticks around in fat and soil, building up in fish and crops. I learned this the hard way living close to a river with a history of illegal dumping. Even years after clean-up, warnings about eating too much local fish remained.

How to Lower the Danger

Dust masks and gloves do little if companies cut corners. Stronger oversight stops much of the risk at the source. Government rules in the U.S. and Europe demand safe waste handling and air scrubbers. Still, not every country adopts those rules. Anyone living or working near factories should push for transparency: test the soil, check water reports, ask about air monitoring. Community groups can pressure for clean-up funds or even relocation when things reach a breaking point.

On a broader scope, safer alternatives in manufacturing reduce the need for chemicals like HCBD. Switches to cleaner processes have already shut down many old production lines. Product designers can pick alternatives in the lab, which cuts down on legacy waste that might resurface in drinking water years later. I’ve seen the difference community organizing makes—a neighborhood gets together, draws attention, and toughens protections both on the ground and in policy. Getting ahead of the contamination always costs less than waiting for damage control.

The Takeaway

Hexachlorobutadiene isn’t a household name, but ignoring it causes real damage. Exposure damages organs, raises cancer risk, and lingers in soil and water far too long. Rules and community action shield people best, backed by honest reporting and real investments in safer technologies. Health matters more than shortcuts or closed-door deals in industry. Knowing about chemicals, what’s in the air or water, lets people speak up and demand better.

Understanding the Risks in Everyday Terms

Hexachlorobutadiene sounds like one of those chemicals you read about in old textbooks and hope you never need to cross paths with. The reality is, companies use this substance in a handful of industries worldwide, and the risk tied to it isn't just a regulatory concern. On the ground, workers see what a mistake can cost—a room filled with toxic vapor, a skin rash that won’t go away, or worse, a fire where nobody wants one.

Beyond Labels: Real Safety Practices Matter

Glass, steel, and other tight-sealing, corrosion-resistant containers stand out as the gold standard for storing hexachlorobutadiene. Leaky drums or basic plastic tanks don’t make the cut. From personal experience working at a chemical plant, nothing makes people sweat like finding a rusted barrel of a solvent that’s been overlooked in a damp corner. Strong, sealed containers head off those moments before they start.

Labeling can’t stop accidents alone, but it does stop confusion. Proper hazard labels, updated inventory logs, and worker training do more than just satisfy OSHA. They bring peace of mind to anybody on the shop floor who wonders what’s inside a certain drum or tank. Transparency and discipline with labels and logbooks, in my experience, sets apart the safe teams from those waiting for a wake-up call.

Temperature, Light, and Air: Enemies of Safe Storage

Storing hexachlorobutadiene away from sunlight, heat, and sources of ignition comes from chemistry, not just policy. Vapors from this chemical can ignite more easily than many realize. Many fires begin from a forgotten space heater or a careless cigarette. Dedicated storage rooms with clear “no smoking” signs, ventilation systems, and a ban on open flames cut risk. I remember a warehouse that got its act together after a near-miss, simply by enforcing these basics and double-checking them during routine safety walks.

Extreme temperature shifts also threaten the integrity of containers. On hot summer days, pressure builds. In freezing temperatures, brittle tanks or pipes may crack. Climate-controlled storage removes this wild card and turns potential emergencies into paperwork.

Neighbours You Don’t Want

Nobody wants hexachlorobutadiene hanging out with oxidizers, acids, or strong bases. People working in storage need solid training on chemical compatibility. A splash or a spill between incompatible substances brings scenes you don’t forget—smoke, fumes, and chaos. Color-coded zones and physical barriers lower the odds, and shared responsibility makes sure everybody has their eyes open.

Emergency Readiness, Not Just Compliance

Spill kits, eyewash stations, fire extinguishers, and established evacuation routes save lives. Dry runs and realistic drills keep teams sharp. Years in industry taught me that readiness doesn’t come from binders on the shelf—it comes from muscle memory and managers who enforce drills like they matter. When alarms ring, the right prep shaves seconds that count.

Safe storage comes down to respecting what hexachlorobutadiene can do in the wrong hands or the wrong conditions. Every step that brings safer containers, better training, and stricter protocols isn’t about ticking off regulations—it’s about sending people home safe at the end of the day.

Real Risks Demand Real Respect

Hexachlorobutadiene, or HCBD, rarely gets headlines outside chemical and industrial circles. Still, anyone who’s worked near it knows you can’t let your guard down. The stuff shows up in places like rubber manufacturing, solvents, and as a byproduct during certain chlorination processes. Coming in direct contact with it, or breathing its vapors, can mess with your kidneys, liver, and central nervous system. It’s also pretty bad for the environment. I’ve seen seasoned techs learn the hard way that overconfidence leads to scary close calls. Nobody enjoys that lesson, so a better way is to keep your head and follow smart protocols from the start.

The Basics Always Matter: Gear and Good Habits

The number one rule for HCBD: treat every ounce of it with suspicion. Forget short sleeves or casual attitudes. My own kit always starts with gloves made for chemical handling—usually ones rated for solvents. Eye protection can’t be optional. Splash goggles with side shields beat regular safety glasses. In a cramped plant, chemical-resistant aprons and full-length suits aren’t overkill; they’re common sense.

Drop a little vigilance, and you wind up with rashes, chemical burns, or something worse. If you can smell anything sharp or sweet, you’re exposed. On big cleanup days, or in tight vessels, a respirator with an organic vapor cartridge is standard. Some places install local exhausts or vent hoods, but you can’t always trust air movement on a busy floor. Trust your PPE, check it for tears, and never grab a break without scrubbing up well.

Handling, Storage, and What Not to Do

HCBD needs containers that won’t corrode or leak. That means high-quality drums or tanks with well-fitting seals. In winter, I’ve seen pipes freeze and split from neglect, so insulation and heating elements sometimes serve double duty—protecting both people and property. Spills can go from small to hazardous with amazing speed. Keep everything labeled, make sure secondary containment trays sit under all drums, and don’t even think about storing food or drinks nearby.

If something goes wrong—a line leaks, or a container gets punctured—you don’t have time to thumb through an emergency binder. Drills matter. Staff should know the exact spill procedures and where to find absorbent pads, neutralizer powders, and eyewash stations. Many workplaces post direct call numbers for emergency services and keep a spill kit within arm’s reach, not locked away behind a dozen boxes.

Stay Ahead with Routine and Respect

Many chemical incidents happen not because of big mistakes, but because of little things—rushing, skipping checklists, not logging inspections. I’ve watched coworkers rely on memory instead of written logs, and pressure from deadlines never helps. Regular training beats one-and-done orientations. Encourage people to speak up about hazards during shift changes, and remind everyone to report issues—no matter how small—before they slip through the cracks.

The facts line up clearly: Direct exposure to HCBD can damage your organs, long-term contact raises cancer risks, and once it spills, cleaning it up isn’t easy or cheap. Following site rules isn’t just about safety compliance. It’s about keeping every shift predictable, proving respect for your own health, and showing the new hires what responsibility really looks like. If everyone stays alert, knows their gear, and avoids shortcuts, dangers shrink. That builds trust—a rare commodity in busy, high-stakes workplaces.

What Is Hexachlorobutadiene and Why It Matters

Hexachlorobutadiene, or HCBD, isn’t a name most people say out loud over dinner. But the stuff turns up in old industrial chemicals and certain pesticide factories, finding its way into landfills or spilling out during hazardous-waste burning. I’ve seen its file in environmental reports – a byproduct most folks would rather not talk about, stubborn and sticky in places it has no business being.

How HCBD Travels and Stays

Once this chemical escapes into the open, cleaning up isn’t just a matter of paper towels and elbow grease. HCBD sticks around. In water, it doesn’t break down easily. It sinks into river mud, latches onto soil, and rides the wind farther than most towns expect. In one study out of Europe, scientists tracked it hundreds of kilometers from its source.

Fish and other critters take in HCBD with every gulp. Their bodies can’t shake the stuff, so it piles up. Big fish eat smaller ones and the chemical loads grow heavier. It isn’t just fish on the hook: the poison keeps moving through birds and even people who depend on those fish. If you’ve ever wondered about warnings taped to fishing docks, persistent chemicals like this are a big reason.

Human and Wildlife Risks

No one signs up for a dose of hexachlorobutadiene. Short-term exposure in workplaces leaves workers with headaches and stomach pain; longer stretches may hurt the kidneys and liver. Lab tests showed possible links to tumors in animals, spurring some governments to classify HCBD as a possible carcinogen.

In wildlife, traces have already disrupted reproduction and development in aquatic animals. Contaminated habitats leave frogs, fish, and fowl struggling to hatch young or fight off disease. Years back, conservation workers along the Great Lakes flagged concerns after seeing persistent organic pollutants like HCBD build up in bird eggs.

What Drives Contamination

This isn’t some villain in a movie. Everyday decisions put HCBD into the environment. Factories dumping their wastes without upgrades, failing to patch up old leaking barrels, or setting fire to garbage piles laced with industrial waste — all build a trail for this chemical to follow. In countries where chemical controls lag, HCBD spills show up more often in streams and drinking wells.

What Helps Lower the Impact

Facing down a chemical this tough takes more than rules on paper. A few things actually cut the risk: better waste treatment tech, tighter leak checks around chemical plants, and switching to safer alternatives for industrial uses. I’ve watched communities push local factories to improve by showing up at town halls with fish test results and water samples.

International agreements also play a hand. The Stockholm Convention flagged HCBD as a substance to eliminate, urging countries to track and destroy it rather than pass the problem along to rivers and farmland. It turns out that regular testing works best when paired with clear reporting, so people know what drifts through their water and food.

Bigger Picture and the Role of Awareness

The fight against chemicals like hexachlorobutadiene stretches over decades. New filters and chemical swaps promise some fixes, but real progress often comes from people keeping tabs on local pollution and holding industry accountable. Any change starts with a clear look at what lives downstream and who is drinking that water.