Ethyl Chloroacetate: From Historical Synthesis to Modern Frontiers

Historical Development

Ethyl chloroacetate traces its discovery back to the late 1800s, not long after organic chemistry started opening doors for researchers keen to manipulate carbon-based compounds. Early syntheses usually involved simple methods that many would consider crude by today’s standards, relying on the straightforward reaction of ethanol with chloroacetic acid. Chemists experimented with this compound, fascinated by its sharp, almost piercing odor and its promise as a building block. By the early 20th century, industrial demand started pushing for more refined synthesis processes, fueling advances that made the compound a mainstay for dye production, pharmaceuticals, and agrochemicals. Anyone who ever sifted through chemical engineering archives will recognize the name cropping up when the world turned to organohalide chemistry for answers in pest control and drug design.

Product Overview

Ethyl chloroacetate sits in the toolbox of specialists seeking a reactive ester. As a colorless, volatile liquid with a high degree of flammability, its infamy in the lab always follows its scent. The compound strikes a balance between reactivity and practicality, often showing up as a reagent for more complex molecules. Those who’ve spent a morning distilling it know what it means to take lab safety seriously because just one careless move can spoil your day—or your health. Industry leans on this molecule, using it to build diverse compounds, from anesthetics to herbicides. Students and researchers alike find themselves handling it in organic synthesis labs, enticed by its potential and warned by its hazards.

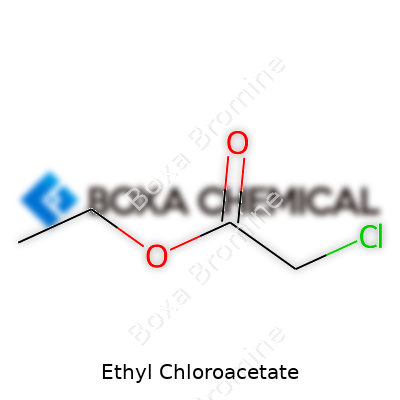

Physical & Chemical Properties

Ethyl chloroacetate boils at about 143–144°C with a density close to 1.16 g/mL at 20°C. Its faintly fruity scent belies the danger beneath the surface. The liquid has limited solubility in water, preferring the company of organic solvents like ether, acetone, or benzene. Chemically, it demonstrates a willingness to donate its chloro group under basic or nucleophilic conditions, making it a frequent pick for alkylation reactions. Its molecular formula, C4H7ClO2, reflects a straightforward structure: two–carbon ethyl foot, a central carbonyl group, and a reactive chlorine atom—a trifecta that draws nucleophiles like a magnet. Years of hands-on work hammer home how unforgiving this molecule can be when mixed with strong bases or reducing agents.

Technical Specifications & Labeling

Bottles and shipping drums carry labels detailing percentage purity (often greater than 98%), CAS registry number 105-39-5, and storage guidelines—store in a cool, dry place, away from heat, open flame, or oxidizing substances. Safety data sheets repeat the warnings: use gloves, goggles, and work under a chemical fume hood. Anyone in procurement learns the hard way the cost of shortchanging safety—spills and exposure can cause acute skin and eye irritation, and inhaling the vapor triggers immediate throat and lung discomfort. Chemical suppliers list shelf life, typical impurity profiles, and recommended container materials (glass or fluoropolymer rather than reactive metals).

Preparation Method

Lab veterans often prepare ethyl chloroacetate through direct esterification. Start with chloroacetic acid and ethanol, add a small volume of concentrated sulfuric acid, then heat the mixture under reflux. Water forms as a byproduct—skilled practitioners remove it to drive the equilibrium toward desired yields. Industrial setups scale this process, using continuous distillation to eliminate the ethyl chloroacetate as soon as it forms, sidestepping chronic hydrolysis. Years of trial-and-error and incremental progress led to better yields and purer product by optimizing temperature, reaction time, and catalyst concentration—efficiency and economics always go hand-in-hand here.

Chemical Reactions & Modifications

Chemists gravitate to ethyl chloroacetate for the dual reactivity of its ester and alkyl chloride groups. The molecule can alkylate nitrogen-containing bases, giving rise to a whole tree of amino acid derivatives and heterocyclic compounds. Under basic conditions, the chlorine swaps places with nucleophiles—amide, thiol, and amine substitutions can all find a home here. Working with this reagent means keeping careful tabs on stoichiometry and purity, as side reactions rapidly scramble reaction outcomes. Decades of organic chemistry papers burst with innovations, swapping, tweaking, and modifying the ester group to access an ever-expanding library of biologically active molecules.

Synonyms & Product Names

Ethyl chloroacetate wears many hats depending on the industry—a researcher flipping through catalogs might spot it called Ethyl monochloroacetate, Chloroacetic acid ethyl ester, or even CAG in shorthand. Variations in labeling depend on supplier, region, and target application, which can cause headaches for anyone reviewing international literature or sourcing raw materials. For the uninitiated, realizing all these names point to the same reactive liquid sometimes feels like a riddle wrapped in paperwork.

Safety & Operational Standards

Working with ethyl chloroacetate gives anyone a crash course in lab safety. The liquid releases vapors that sting the eyes and airways, so every storage cabinet and bench relies on solid ventilation and solvent-resistant gloves. Occupational safety rules call for airtight containers, chemical spill kits, and strict tracking of inventory. In larger plants, automated monitoring for leaks and ventilation failures helps keep workers safe. Anyone who’s faced a near-miss with a leaky bottle or forgotten ventilator hood comes away deeply respectful of detailed standard operating procedures and emergency drills. OSHA and analogous international bodies list ethyl chloroacetate as hazardous, flagging its toxicity, strong irritant effects, and high flammability.

Application Area

Farmers and agrochemical engineers see ethyl chloroacetate as a precursor for herbicides and pesticides targeting tough weeds. In the pharmaceutical arena, drug designers build painkillers, muscle relaxants, and anti-infective agents starting from this molecule. It keeps turning up in organic synthesis, where researchers branch out into dyes, flavors, fragrances, and specialty polymers. Its reactivity gives chemists the flexibility to make otherwise stubborn carbon-carbon or carbon-nitrogen bonds. Techs in industrial labs spend countless hours developing downstream reactions based on ethyl chloroacetate, using it to jumpstart the production of more complex intermediates.

Research & Development

As environmental rules and expectations shift, chemical engineers rethink production and application strategies. Current projects target greener synthesis methods—less waste, fewer emissions, lower energy consumption. Research groups test alternative catalysts, solvent systems, and continuous-flow technologies to increase safety and yield. New uses keep surfacing for ethyl chloroacetate in targeted drug delivery, enzyme inhibitors, or as specialty building blocks in functional materials. Academic and industry collaboration grows stronger as both sides chase breakthroughs that balance commercial impact with environmental safety.

Toxicity Research

Reports on animal toxicity paint a clear picture—ethyl chloroacetate is no benign substance. Acute exposure leads to central nervous system depression, respiratory distress, and skin or eye damage. Chronic contact builds up problems in the liver and kidneys, driving researchers to chart exposure limits and best handling practices. Animal studies, plus a handful of human case reports, drive hazard classification and inform safety protocols. Over the years, toxicologists pushed for better detection systems and tighter workplace exposure standards, knowing that small spills in the wrong hands can cause outsized harm.

Future Prospects

Chemical industries won’t drop ethyl chloroacetate any time soon—the molecule underpins breakthroughs in pharmaceuticals, crop protection, and functional materials. Stricter safety and environmental rules push everyone involved to change their practices, invest in new ‘green chemistry’ tools, and double down on worker training. R&D teams look at bio-based feedstocks, alternative synthetic routes, and safer derivative molecules. Young scientists in the field push for reactor systems that trap emissions and minimize waste. As new frontiers open in medicinal chemistry and polymer sciences, this compound remains a staple, its usefulness tied to a commitment to progress, safety, and environmental care.

Ethyl chloroacetate rarely makes headlines, but its fingerprints show up across chemistry labs, industrial plants, and even the world of pharmaceuticals. This clear liquid pulls more weight than most people imagine, all because of its reactive nature and unique chemical structure. My time in research taught me that a single compound often nudges a whole process forward or stops it cold. Ethyl chloroacetate fills that kind of role, especially when people want to build something from the ground up in the lab.

Engineering Molecules: The Kickoff Reagent

In organic synthesis, ethyl chloroacetate acts almost like a starter’s pistol. Chemists rely on it to introduce useful fragments into bigger molecules. Its most popular claim to fame comes from the production of glycine, one of the amino acids that get pumped into food supplements and medicines. The process starts simple: chloroacetylation, where ethyl chloroacetate helps join other base chemicals, sets the table for the entire sequence.

Sitting in graduate labs, I watched this reaction play out. One careful addition of ethyl chloroacetate, and you get a pathway to dozens of important molecules. Without it, researchers would face roadblocks every step of the way.

Farm Fields and Pharmaceuticals

Bigger companies see dollars in the ability to use ethyl chloroacetate for pesticides and herbicides. Its presence shapes the early steps leading to agrochemical ingredients that keep fields productive. If you spend any time around a seed company or an agrochemical supplier, you’ll spot its name buried in formulation documents. These aren’t just academic exercises—the right reaction saves crops, brings bigger yields, and helps feed cities year after year.

The story changes again with pharmaceuticals. Drug makers seek purity and precision. Ethyl chloroacetate offers the right mix of reactivity and predictability for crafting building blocks in painkillers, sedatives, and other medicines. Fewer impurities slip through when controlled batches start with this reagent. Quality counts because the end of the line always leads to someone’s health.

Risks on the Table

Working with ethyl chloroacetate demands respect. Inhaling its vapors causes severe irritation, and any contact with skin quickly leads to burns. I remember lab colleagues telling stories of accidental splashes, emergency washes, and ruined afternoons. Factory managers and small labs both need strict protocols in place—goggles, gloves, and plenty of training. Standard practice centers on using fume hoods, careful storage, and written safety procedures. The stakes run high, and one careless move leaves painful reminders.

Room for Better Safety and Cleaner Processes

Ethyl chloroacetate keeps proving itself as a reliable partner in labs and factories, but workers and the environment pay a price if companies cut corners. Companies can swap out outdated equipment for closed-loop reactors. Automation trims down human error. Local regulators set benchmarks for handling and disposal, but real improvements show up when workers buy in and report problems early.

There’s an opportunity here for chemists to design less hazardous alternatives using green chemistry techniques. That work won’t happen overnight, but years of minor improvements add up. For now, careful handling, smart engineering, and open eyes offer the best answer to the questions this chemical raises. Risk and reward linger side by side in the world of industrial chemistry, where every substance—ethyl chloroacetate included—gets judged by how it’s managed.

The Real Hazards of Ethyl Chloroacetate

Ethyl chloroacetate never really announces itself. You might open the bottle and catch a whiff—strong, sharp, almost sweet—and realize fast that it’s not the kind of thing you want on your skin or in your lungs. The chemical packs a punch: it’s toxic, causes burns, damages eyes, and fires start easily if you’re careless. The folks who spend time with it know it, and that’s why real care goes into every step of working with this stuff.

Getting Ready Before You Start

Walking into the lab, safety starts with what you wear. Old stories circulate in the chemical sciences—somebody’s gloves broke, or they skipped the face shield because it fogged up. It takes only one mistake to change a career or even end one. The right approach uses goggles, long-sleeved lab coats, chemical-resistant gloves, and, when the project calls for it, a face shield on top. Ventilation counts for a lot. Fume hoods aren’t decoration—they’re the only line standing between you and a room full of hazardous vapors.

Storage That Actually Keeps People Safe

I’ve seen bottles of ethyl chloroacetate shoved on crowded shelves, capped loosely, over open drains. That’s a good way to ruin everyone’s afternoon. Good storage means sealing containers tight, labeling everything clearly, and stashing it somewhere cool, away from direct sunlight and any spark or open flame. Flammable liquids demand respect, not shortcuts. Segregation from other reactive materials matters; acids and bases shouldn’t share space with this kind of chemical.

Everyday Handling Routines that Really Matter

Pouring from a large bottle tempts anyone into risky shortcuts. Pour slow and over containment trays. Spills aren’t something to shrug off. Keep spill kits handy—absorbent pads, neutralizing agents, and plenty of water. Folks on my team practice with these kits every few months, not because emergencies are frequent, but because muscle memory makes all the difference when hands are shaking. Skin or eyes catch a drop? Rinse—immediately—with running water, then seek medical care. No hesitation—delayed action has real consequences.

Prepping for Fires and Exposures

Fire extinguishers (CO2 preferred), safety showers, and eyewash fountains stay accessible. Training isn’t a box to tick at orientation; running drills makes emergency response feel automatic. Ethyl chloroacetate has low flash point—it doesn’t need much encouragment to catch fire, especially near heat sources or static discharge. Good housekeeping habits—clean benches, no clutter—add a layer of security that feels less dramatic, but saves real headaches.

Health Awareness: Listening to What Your Body Tells You

Even tiny exposures accumulate. Headaches, eye pain, sore throat—anyone who’s felt it remembers that “it’ll pass” is the wrong attitude. Experiencing symptoms means taking a step back, reporting up the line, and seeing a doctor. The Material Safety Data Sheet belongs within reach, not filed away in a binder nobody checks, and reviewing it before touching the chemical stays a smart move.

Safer Chemistry—Not Just Rules, but Culture

Skepticism about short cuts builds safer routines. Open communication between co-workers and supervisors shifts the mindset from ticking boxes to genuine care about what goes home on your skin, your clothes, your lungs. Encouraging peers to speak up—not just about their own comfort, but about sketchy procedures or broken equipment—prevents tragedies. Document hazards, review incidents, and check each other’s PPE. Personal responsibility, shared accountability, and a healthy dose of respect for these chemicals create a safety culture that keeps people out of harm’s way.

The Basic Chemistry of Ethyl Chloroacetate

Ethyl chloroacetate stands as a clear example of how small changes in a molecule create different properties and uses. Its chemical formula is C4H7ClO2, a simple collection of carbon, hydrogen, chlorine, and oxygen. In day-to-day chemistry, this means you’ve got an ethyl group (CH3CH2) attached to a chloroacetate backbone. It sounds technical, but that formula shows how a little twist—a chlorine atom in place of a hydrogen—can have big effects.

Why the Formula Actually Matters

Chemical formulas tell more than what’s inside a flask. That one chlorine atom in C4H7ClO2 changes how the molecule reacts. Without numbers and symbols, industrial chemists would have trouble making pharmaceuticals and crop protectants safely. Ethyl chloroacetate’s formula guides manufacturers who measure, mix, and handle barrels of it by the ton. I’ve watched in labs as strict white labels and careful double-checking keep everyone honest because one wrong number can send a reaction off course or worse, create a dangerous byproduct.

Applications in Medicine and Beyond

I’ve seen ethyl chloroacetate put to work in projects on pesticide development, pain relievers, and even local anesthetics. Its formula C4H7ClO2 makes the molecule reactive enough to attach to other groups, all under strict control. These reactions build new compounds that form ingredients in drugs or help fight plant disease. Years ago, my biochemistry professor walked us through a synthesis using ethyl chloroacetate, pointing out exactly how its formula dictates what steps are safe and which simply won’t work. It’s a tool in the chemist’s kit, valued for its predictability and reliability.

Safety and Handling: A Formula With Responsibility

Having worked in shared university labs, I’ve seen how a clear formula helps manage safety. Ethyl chloroacetate’s chlorine atom means it gives off harsh fumes and can irritate skin fast. Clear labeling based on C4H7ClO2, plus accessible safety sheets, kept students and staff out of trouble. The formula underlines the need for goggles, gloves, and open windows, not just for the sake of rules but because mistakes bring real harm. Factories use the same approach on a much larger scale—every drum shipment references the chemical formula before workers even crack a seal.

Room for Responsible Progress

There’s an ongoing push for greener ways to make and use chemicals. The structure of ethyl chloroacetate means some alternative starting materials won’t do the job, but improved ventilation, better storage, and safer reaction designs keep risk in check. Some startups now offer digital hazard alerts built right off molecular formulas like C4H7ClO2, giving hands-on workers just-in-time information. This pays dividends in safety and cuts environmental waste. The formula acts as a shorthand for all those safety points—easy for veterans and newcomers to grasp alike.

Staying Accurate Builds Trust

Consistent use of the correct chemical formula matters more than most realize. Whether a student is drafting a lab report or a manufacturer is uploading a batch record, accuracy matters to stay in compliance and keep people safe. Slip-ups in a formula don’t just waste money—they risk lives, pollute water, and stall important projects. It’s a detail that makes labs, factories, and medicine more reliable for everyone.

Handle With Eyes Wide Open

Ethyl chloroacetate isn’t your average household chemical. Its distinctive scent, strong volatility, and reactivity create some real challenges for anyone dealing with it, whether inside universities, research labs, or specialty manufacturing floors. Miss a tiny step in controlling this chemical and consequences quickly spiral—skin burns, violent reactions, or even toxic exposure. That’s not scaremongering, just an honest view from working several years alongside organic synthesis teams and seeing how even routine storage can go wrong.

Why Air and Moisture Are Not Friends Here

Leave a bottle open on a bench? Vapors rush out. Let humidity get in? The compound starts to break down. I’ve seen folks lose entire batches to simple carelessness. Ethyl chloroacetate attacks the skin and lungs if allowed to leak into the room, but most folks miss that it quietly reacts with water in the air too. This interaction produces hydrochloric acid—another nasty risk.

Containers That Protect, Not Just Hold

The old glass screw-cap bottles can work, but only with tight-sealing Teflon liners and firm checks for chips or cracks. Metal, especially anything with iron or steel, stays completely out of the question. It’s always about using chemical-resistant glass or approved plastics. A cheap plastic bottle spells disaster—corrosion, leaks, or a bottle bottom softening over weeks. From a personal note, I learned to label everything twice and check seals every use. Returning the bottle straight to its secondary container, such as a plastic bin with absorbent pads, kept bench accidents rare and cleanup quick if something did go wrong.

Cool, Dark, and Out of Reach

Direct sunlight nudges many chemicals toward rapid decay, and ethyl chloroacetate shows little forgiveness. Temperatures should stay consistently cool—think a chemical fridge or, at the very least, a cool storeroom below 25°C. Most institutional labs now segregate flammables, poisons, and reactive agents in separate metal cabinets. Shelves shouldn’t bow or shake, and each bottle rests spaced apart to prevent unnoticed drips or contact between chemicals. In my experience, storing this compound at eye level reduces lifting accidents and lets staff check labels and seals faster. Never stack other items on top of a bottle. Each layer adds risk, especially when people hurry at the end of the day.

Ventilation and Emergency Prep Still Matter

Strong fume extraction handles any accidental spill or vapor escape. Don’t count on just an office vent. Purpose-built fume hoods and ventilated cabinets act as a real barrier when dealing with volatile stuff like this. A mistake I’ve seen—improvised storage under a bench near a standard air vent. Vapors crept out into the lab, and a careless researcher felt the effects for weeks. Emergency eyewash stations, clean nitrile gloves, and face shields should stay within arm’s reach. It may feel inconvenient, but the discomfort of injury sticks around a lot longer. I’ve worked in labs with robust checklists for hazardous substances—everyone, including students, got checked and retrained every six months. Mistakes became stories we learned from instead of repeating them.

Accountability and Trusted Procedures

Lab managers carry real responsibility—regular audits, digital tracking of chemical stocks, and sudden inspections to ensure safe habits don’t slide. Full transparency in chemical handling stops shortcuts. As someone who’s seen the results of both strict and loose systems, trust me: those who take written logs and hazard training seriously avoid scary close calls. Even simple solutions, like routine reminder emails about how to store and label the most dangerous chemicals, save lives. Clear standards work. Respect for ethyl chloroacetate, backed by tested protocols and plenty of common sense, builds safer labs and healthier workplaces.

Why Ethyl Chloroacetate Poses a Serious Risk

Ethyl chloroacetate isn’t a household name, but its dangers deserve real attention. People may find themselves working with it in chemistry labs, factories, or specialty manufacturing. In the same way that nobody takes a power tool lightly, this colorless liquid can cause serious harm with just a bit of careless contact.

Breathing in vapors irritates the nose, throat, and lungs. One whiff triggers coughing, throat tightness, or even a suffocating feeling. Short exposure leaves reddened eyes and irritated skin. Longer or stronger contact can burn the eyes and skin, cause blistering, and, in extreme cases, cut off your ability to breathe. The body can absorb ethyl chloroacetate through the skin, leading to poisoning symptoms like nausea, dizziness, confusion, and headache. Swallowing it threatens far more: it brings burning pain, vomiting, and—if treatment fails—permanent organ damage.

Plenty of chemicals bring these sorts of dangers, but ethyl chloroacetate has one more trick: flammability. Vapors catch fire at temperatures most workshops see during summer, so careless storage or transfer creates more than a health risk—it’s a fire waiting to happen. It’s worth noting that the chemical comes with a harsh, recognizable smell, and that can at least give a bit of early warning if a leak begins.

What Real-World First Aid Looks Like

Many people freeze up at the thought of chemical exposure. Panic doesn’t help. If skin meets the liquid, speed is everything. Take off clothing touched by the chemical. Wash with plenty of water—at least 15 minutes. With chemical burns, gentle but thorough rinsing can limit how much poison gets into your system.

Splashing into eyes proves even more urgent. Hold eyelids open and rinse eyes using cool water, not just for a few moments, but for a solid 15 minutes. Don’t wait to see if burning goes away—get professional medical help right away, even during rinsing if someone else can call. Delaying only increases the risk of vision loss.

Breathing in ethyl chloroacetate stings and swells the airways. Move quickly to fresh air as soon as you notice exposure. Loosen tight clothing, and watch for warning signs like chest pain, wheezing, or confusion. These hint at deeper trouble. If the victim can’t breathe easily after moving outside, go to a hospital; they’ll need more than rest.

Swallowing any amount is a medical emergency. Don’t try to make yourself vomit or drink anything unless a poison center or doctor says to. Seek medical help as quickly as possible. Ethyl chloroacetate can damage organs before you feel the worst effects.

Reducing Risk Starts with Preparedness

Working around ethyl chloroacetate requires more than gloves and goggles. Spill kits, safety training, proper storage, and easy access to eyewash stations matter as much as any protective equipment. Many workplaces skip practice drills or push the bare minimum, but after seeing minor spills turn dangerous, I’ve come to appreciate how fast chemical exposure becomes overwhelming.

A no-nonsense approach makes a difference: Label every container. Teach the hazards. Insist on double-checks. Reinforce the value of reporting leaks—never let a “small drip” go unreported. The right habits, not just strict rules, keep people clear of harm.

Ethyl chloroacetate won’t forgive mistakes. Anyone working near it should know the risks, learn the first aid, and always choose caution over shortcuts.