Ethanesulfonyl Chloride: An In-Depth Commentary

Historical Development

Ethanesulfonyl chloride first appeared in lab protocols during the early twentieth century when sulfonation methods exploded in the toolbox of organic synthesis. Early chemists realized that sulfonyl chlorides like this one could introduce key functional groups in molecular frameworks, which powered the expansion of dyes, pharmaceuticals, and agrochemicals. Over the decades, demand for chemical building blocks like ethanesulfonyl chloride has surged, mainly because research chemists and industrial formulators want reagents that help shape molecules cleanly. The way expertise accumulates involves not just laboratory breakthroughs but also careful refinement in factories and scale-up operations. Key improvements in sulfonation chemistry—like better temperature control or purer precursors—paved the road for the reliable supplies modern producers manage today.

Product Overview

Ethanesulfonyl chloride stands out as a versatile chlorinated sulfonic acid derivative with the formula C2H5SO2Cl. Most chemists reach for this compound during the synthesis of complex sulfonamides, in the fine-tuning of molecules found in new drugs, or as an intermediate that helps build more specialized reagents. Its commercial availability in drums and bottles often arises from strong demand in organic and medicinal chemistry, as well as in the production of performance materials. Industry professionals gravitate towards this reagent due to its ability to introduce sulfonyl functional groups without piling on extra byproducts or clogging up downstream reactions. Having worked in a lab, I always trust specialty third-party suppliers with an eye for purity, since even minor contamination can trip up subsequent steps in a multi-stage synthesis.

Physical & Chemical Properties

On the bench, ethanesulfonyl chloride appears as a clear, oily liquid with a piercing, acrid odor. The boiling point lies around 185-190°C, and it doesn’t mix well with water, steering lab workers to use it under dry conditions. It dissolves in most organic solvents like dichloromethane, chloroform, or ethyl acetate. The molecule’s high reactivity stems from its sulfonyl chloride group, which makes it prone to nucleophilic substitution reactions. Prolonged exposure to air and moisture causes it to hydrolyze, producing ethanesulfonic acid and hydrochloric acid, both corrosive byproducts that matter during storage and disposal. From my experience, it’s wise to set up all reactions in a fume hood and wear gloves, since this chemical typifies the “irritant” category in most safety databases.

Technical Specifications & Labeling

Quality assurance teams assign strict thresholds for ethanesulfonyl chloride’s purity—generally, products hitting over 98% purity work for nearly all laboratory and industrial processes, though research-level synthesis might push for even cleaner grades. Reputable suppliers attach detailed certificates of analysis outlining minimum content of the main compound, identity checks by IR, GC, or NMR, water content, and color index. Standard UN labeling applies, flagging it as a corrosive, environmentally hazardous substance. Proper technical documentation gives chemists confidence when planning reactions or troubleshooting unexpected behaviors. It’s not just about regulatory compliance; knowing the exact residuals present in each batch helps avoid costly cleanups later on.

Preparation Method

Making ethanesulfonyl chloride typically starts from ethane or ethanesulfonic acid, which then undergoes chlorination using compounds such as phosphorus pentachloride, thionyl chloride, or chlorosulfonic acid. Industrial-scale reactors cool the chlorination mixture, handle evolving gases, and isolate the product by distillation, all under carefully monitored conditions to keep variable impurities in check. Some smaller producers rely on batch operations, giving lab managers direct control over temperature ramps and residence times. Achieving a high-purity product demands both precise reagent measurement and watchful purification steps after synthesis, whether by vacuum distillation or repeated washing.

Chemical Reactions & Modifications

Ethanesulfonyl chloride acts as a workhorse in sulfonamide coupling reactions, linking to amines and other nucleophiles to create new drugs, pesticide agents, and specialty materials. The compound can transfer its sulfonyl group onto a huge range of molecular scaffolds, setting up further modification by hydrogenation or cross-coupling techniques. Chemists also exploit its compatibility with Friedel-Crafts or Grignard-type chemistry in more ambitious synthetic programs. Side-product control remains a big deal since hydrolysis generates acidic fumes and wastes—not only a hazard but also a purity issue in finished goods. Nothing frustrates a researcher more than batch-to-batch variability or an unexpected impurity derailing a long synthesis run.

Synonyms & Product Names

Ethanesulfonyl chloride goes by several names in global catalogs, including ethylsulfonyl chloride and 1-chloroethanesulfonic acid. In different languages or brands, the label may change but the chemical structure remains constant, so double-checking CAS numbers cuts confusion when stocking a lab or ordering for a factory. In regulatory filings, each name links back to C2H5SO2Cl, which helps keep compliance documentation consistent no matter the supply route taken.

Safety & Operational Standards

Lab safety officers treat ethanesulfonyl chloride as a high-risk chemical, demanding storage in cool, dry spaces away from bases, water, and sources of ignition. Spills bite skin and irritate lungs, so full PPE—gloves, goggles, lab coat, and sometimes a respirator—becomes non-negotiable. Message boards in my research group told horror stories about accidental releases, stressing meticulous weighing and cleaning to minimize risk. Disposal happens via neutralization under controlled conditions, with waste barrels vented and monitored for vapor leaks. OSHA, REACH, and GHS guidelines shape every phase of handling, extending from transport to long-term storage.

Application Area

In pharmaceuticals, ethanesulfonyl chloride speeds the synthesis of active molecules like sulfonamide antibiotics or anticancer agents. Agrochemical designers turn to it when tailoring new pesticides and herbicides that depend on precise sulfonyl group placement. Polymer science researchers regard it as a cornerstone for making specialty plastics or performance coatings resistant to heat, flame, or abrasion. Years spent in R&D taught me how small tweaks in reagent quality or reaction timing dictate whether a vital chemical innovation succeeds or stalls out in pilot testing. Those elegant molecular couplings found in chemistry textbooks start with well-chosen reagents like ethanesulfonyl chloride, not abstract recipes.

Research & Development

Many research teams focus on reducing waste in sulfonyl chloride production or developing greener pathways that use fewer toxic reagents. Catalytic systems and continuous-flow reactors draw grant funding for their promise to shrink environmental footprints without sacrificing the compound’s utility. Another hot topic in conference circuits covers selective functionalization, where new ligands or bases help steer the reactivity towards only one spot in a molecule—minimizing clean-up costs and simplifying post-processing. Academic-lab partnerships with industrial process engineers continue to set benchmarks for how safely and efficiently this compound can be made at larger scales.

Toxicity Research

Toxicologists issue clear warnings about ethanesulfonyl chloride, since animal studies show it can burn tissue and trigger respiratory problems even on brief exposure. Chronic handling risks cumulative effects, especially for workers in manufacturing plants lacking proper protective gear. My own time in the lab hammered home the importance of daily vigilance: keep container lids tight, never pipette by mouth, and have emergency washes on standby. Regulators set workplace exposure limits, based on both acute and chronic data, to keep injury and illness at bay. Long-term research tracks waste breakdown products, aiming to better understand how residues behave in soil or waterways.

Future Prospects

Down the road, the quest for safer sulfonylation tools and environmentally friendly reaction schemes shapes how ethanesulfonyl chloride gets discussed at industry summits and university seminars. Biobased alternatives and smart reactor designs stand poised to cut back hazardous waste while scaling up output to meet rising demand in pharmaceuticals, energy, and materials science. Startups and established corporations both invest in digital process monitoring, hoping to catch anomalies before they lead to downtime or costly recalls. A future where raw reagents perform with utmost efficiency and safety depends not just on clever synthetic routes, but also meaningful collaboration across regulatory, scientific, and operational lines.

A Closer Look at an Unfamiliar Chemical

Stepping into a chemical lab, you quickly see there is a tool for every job. Ethanesulfonyl chloride is one of those chemicals tucked away on a shelf, usually found in laboratories that work with pharmaceuticals or fine chemicals. Many folks never hear about it, but its impact shows up across different industries.

Building Block in Pharmaceuticals

Drug development often starts with small steps. Ethanesulfonyl chloride acts as a building block, bringing reactive sulfonyl groups into larger, more complex molecules. Chemists rely on it to produce sulfonamides, which form the backbone of some antibiotics and diabetes medications. The structure of ethane sulfonyl chloride gives scientists a way to attach groups that bring about specific drug actions. Sometimes, a change as small as swapping a single group attached to a ring makes all the difference in how well a medicine works. I have seen research teams experiment with dozens of versions just to optimize one compound, and they often reach for ethanesulfonyl chloride when they want something stable but reactive.

Sequences in Organic Synthesis

Anyone who has spent nights planning syntheses knows that small reagents make or break a process. Ethanesulfonyl chloride activates certain parts of a molecule, allowing for reactions that might be tough under normal conditions. Researchers use it to add sulfonate groups or protect areas of a molecule while they work on other spots. This strategy pops up in the production of dyes, agrochemicals, and specialty polymers.

Industrial and Specialty Polymer Applications

Performance plastics and coatings often demand more than simple carbon chains. Sulfonate groups, added with ethanesulfonyl chloride, offer better slipperiness, static resistance, and chemical toughness. Manufacturers of ion-exchange resins—vital for water treatment or certain types of batteries—depend on these groups because they bind or release ions efficiently. Ethanesulfonyl chloride gives them a direct, controllable path for this type of modification.

Risks and Responsible Handling

Working with ethanesulfonyl chloride is not a casual affair. The liquid reacts with moisture to release hydrochloric acid, which stings eyes and skin and creates a hazard in the wrong hands. Any chemist worth their salt will stress the importance of gloves, fume hoods, and solid storage practices. Mishandling has led to severe injuries and ruined equipment, but so has careless disposal—neutralizing before dumping keeps public health and the environment safer.

Room for Safer Alternatives

The world moves toward greener and safer chemical tools every year. Ethanesulfonyl chloride still stands strong for certain reactions, but researchers continue to uncover substitutes with lower toxicity and custom-tailored reactivity. Years ago, high school students might never have heard about safe chemical handling; today, awareness spills over into university labs and even into conversation between policy makers and industry leaders.

Paths for Improvement

Better labeling, smarter engineering controls, and more accessible safety training help cut back risks. Clear communication between suppliers and end users matters too. The more openly we discuss potential substitutions—especially as regulations on harmful chemicals tighten—the smoother industry adapts. Direct experience shows that a shared commitment to health leads to better outcomes for both workers and consumers. That attitude, more than any one chemical, pushes technology ahead.

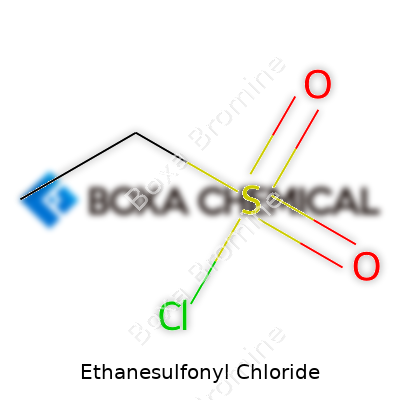

Getting Down to the Basics: C2H5SO2Cl

Plenty of folks who've spent time in a chemistry lab recognize how useful a solid understanding of chemical formulas can be. Ethanesulfonyl chloride, with its formula C2H5SO2Cl, pops up whenever sulfonation reactions or functional group transformations come into play. The backbone of this molecule is straightforward: two carbons, five hydrogens, one sulfur, two oxygens, and a chlorine atom. That structure gives it unique chemical punch in organic synthesis.

Why Chemists Care About This Compound

I’ve mixed and measured my fair share of reagents in various roles, and this compound’s value stands out. Its chemical structure lets it act as a sulfonylating agent. This means it’s pretty handy for making sulfonamides, sulfonylureas, and other key bits for medicines and agricultural chemicals. In my experience, processes using this molecule require care because the sulfonyl chloride group is reactive—and that reactivity brings both opportunity and hazard. Mixing up a batch of pharmaceuticals or pesticides without triple-checking your chemicals isn’t just sloppy; it can be dangerous.

Reactivity Means Responsibility

Chemicals like ethanesulfonyl chloride illustrate the need for solid lab safety. Chlorinated sulfonyl groups won’t hesitate to react with water. You’ll get a mess of hydrochloric acid gas—harsh on your lungs and rough on the folks nearby. Safety data sets out how to handle this risk, but practical experience tells you to work under a fume hood, wear gloves, and double-check ventilation. One puff of the wrong gas leaves memories that stick.

Knowing the Formula Helps Prevent Mistakes

Getting the formula right lets you predict how a compound behaves in reactions. Forget just writing C2H5SO2Cl on a bottle; knowing what it means changes how you treat it. For example, that chlorine attached to sulfur signals a risk for chlorination byproducts—a concern when scaling up reactions for industry. People who understand these details make fewer mistakes, avoid costly clean-ups, and keep colleagues safer.

Beyond the Lab Bench: Environmental Impact

Making and breaking down ethanesulfonyl chloride carries environmental burdens. Release of byproducts like sulfur dioxide or hydrochloric acid into the environment causes real harm. Facts pulled from real-world spills show short-term damage to aquatic life and long-term soil disruption. I’ve seen regulations get tighter around chlorinated chemicals, and for good reason. Less waste means clearer water downstream and fewer regulatory headaches for companies doing the work right in the first place.

Smarter Chemistry Starts with the Fundamentals

Solid chemical literacy helps spot new risks and better solutions. Tech advances let researchers swap out hazardous reagents for greener alternatives, often by tweaking the formula or using catalysts that sidestep noxious byproducts. This is changing the landscape for industrial chemistry, not just in the classroom but on the production floor.

Understanding the formula shapes how we handle chemicals and how we move science forward. Success in chemistry, whether mixing a gram or a ton, starts with knowing what’s in the bottle—and respecting every atom it brings to the bench.

The Risks with Ethanesulfonyl Chloride

I’ve spent enough time working in labs to know the sharp, acrid scent that comes with certain chemicals. Ethanesulfonyl chloride isn’t something you forget. It gives off fumes, and contact with moisture kicks off a dangerous reaction. It gets under your skin—sometimes literally—because it tears up the eyes and lungs, and burns on the skin can get serious before you know it. Proper respect for this compound spells the difference between a routine experiment and a hospital visit.

PPE: Suit Up, Don’t Cut Corners

Lab coats and goggles don’t just collect dust—use them every single time. Splash goggles guard your eyes from the smallest droplet. I learned early that nitrile gloves often don’t hold up against sulfonyl chlorides for long. Switch them out often, and double up for good measure. Face shields take a moment to put on and make a huge difference if anything splashes. I keep chemical-resistant aprons handy for jobs involving larger volumes. With this compound, every piece of gear counts.

Ventilation Isn’t Optional

I still remember my first year, thinking a cracked window was enough. That doesn’t cut it. Fume hoods are essential. Good air exchange in the workspace stops fumes before they reach your lungs. If a hood isn’t working or is missing a sash, don’t touch the bottle until the problem’s fixed. Respirators rarely come into play, but they can add a layer of safety if ventilation leaves you exposed for any reason. If your eyes or nose pick up even a hint of its bite, step back and fix the airflow before doing anything else.

Keep Water Far Away

Ethanesulfonyl chloride and water are a nasty mix. Add any to the other, and you get hydrochloric acid, heat, and choking gas. I avoid open sinks and wet benches whenever I handle it. Dry glassware and tools go a long way. If a spill lands on water—on the bench, floor, or your own hands—the reaction can be instant and dangerous. Approach cleanup with care and only use proper absorbents, not water-based towels or mops.

Storage and Labeling: Clarity Matters

Store it in a cool, dry place, far from acids, bases, and solvents that react violently. Label every bottle so there’s no guessing. I’ve seen too many near-misses with chemicals stored in reused containers. Secure the cap tightly, and don’t move the bottle around more than necessary. If you’re handed a mystery bottle, double check before opening—errors with this chemical can hurt more than your pride.

Spill Response and Emergency Prep

Spills aren’t the time to improvise. Grab a chemical spill kit designed for corrosives. Neutralize with agents that won’t cause a bigger reaction. If someone gets splashed, use an eyewash station or shower right away—even if the burn feels mild. Medical help comes next, since these injuries tend to get worse over time. Keep emergency contacts and protocols visible and review them with new team members regularly. It’s the kind of forward thinking that can make all the difference in a crisis.

Building a Culture of Safety

Handling ethanesulfonyl chloride safely isn’t just about following rules for the sake of compliance—it’s about going home at the end of the day without injuries or regrets. Training never stops, and sharing near-misses or hard lessons helps the whole team get better. Culture grows strongest when everyone looks out for one another, watches for small failures, and keeps asking questions. Confidence in handling tough chemicals grows from habits built on real experience—and a stubborn insistence on doing things right every time.

Chemistry in Everyday Life

Anyone who’s spent time around a laboratory bench knows how much a simple question about a chemical can spark a deeper conversation. Ethanesulfonyl chloride might not sound particularly exciting at first, but this compound plays a role in industries ranging from pharmaceuticals to dye manufacture. People looking for straightforward information about it often stumble on technical jargon. Let’s talk about the heart of the issue: whether ethanesulfonyl chloride dissolves in water, and why anyone working in a lab—or just curious—should care.

Bringing Science Down to the Table

The molecule has a sulfonyl chloride group and a short ethyl chain. Some will expect that chlorine hanging off a group would lead straight to water dissolving powers. Yet, reality tells a different story. The chloride group in this context isn’t in the form most of us remember from table salt; it’s attached to sulfur and doesn’t ionize the same way. Ethanesulfonyl chloride comes as a colorless liquid, and most lists mention low solubility in water. Why does this happen? That sulfonyl chloride group interacts with water, but the process can get messy.

Digging Into the Details

Mix ethanesulfonyl chloride with water, some hydrolysis starts. The molecule reacts, chopping itself up and creating not just ethanesulfonic acid, but also hydrochloric acid in the mix. The bad news for anyone running a reaction: you're not just dissolving a compound. You’re dealing with byproducts that may corrode equipment or shift the pH in unpredictable directions. The original compound doesn’t just slide quietly into solution; it keeps changing.

Researchers and chemical handling guides agree the solubility sits at “low” or sometimes “decomposes in water.” Instead of a tidy solution, you end up with a cloud of reactions and, potentially, safety risks. I’ve spilled my share of reagents. Watching a perfectly clear solution start to bubble or become cloudy without warning stays in your memory. That surprise is a clue—ethanesulfonyl chloride does not simply dissolve.

Risks and Real-World Lessons

Handling something that reacts with water takes more than just curiosity—it means taking real steps to protect yourself. Lab workers need gloves, safety goggles, and a chemical fume hood. If a spill happens, water isn't always the right cleanup material. Instead, sand or inert absorbent compound works better to scoop up excess chemical before it gets wet. Hydrochloric acid vapors sting the nose and eyes—a reminder that this isn’t a bench-top water-and-stir kind of situation.

Looking Forward: Knowledge as Safety

There’s something powerful about asking why a molecule dissolves, beyond textbook knowledge. People need access to honest, clear information about chemicals they encounter in work or study. Transparency about risks—such as the hydrolysis leading to acid formation—could save equipment, prevent burns, and keep the workplace safer.

Industries aiming to use ethanesulfonyl chloride for synthesis usually turn to non-aqueous solvents like dichloromethane or chloroform. Using the right setup helps avoid the free acid and unwanted side reactions. Anyone who learns about solubility ends up with a better handle on how to work safer and smarter. Sometimes, the practical lesson means remembering that just because a bottle looks ordinary, a splash can set off an unexpected chain of events.

Why Storage Matters in the Real World

I’ve spent a fair share of time around labs, and one thing you pick up quick is that poor storage decisions create problems no one wants to clean up. Ethanessulfonyl chloride isn’t an everyday chemical for most people, but for research labs, pharmaceutical development, and specialty manufacturing, handling and storing it safely isn’t optional. It reacts with water to generate hydrochloric acid and toxic fumes, so keeping it secure isn’t just following the rules—it’s about not putting people or equipment at risk.

Don’t Trust Room Temperature

I’ve seen more than one project slowed down by assuming that “cool and dry” is just a suggestion. Ethanessulfonyl chloride comes with a short fuse. Warm, humid air speeds up its decomposition. The safest bet sits below 25°C, ideally down in the low teens if you can manage it. Refrigerators set for chemicals, not food, really serve a purpose here. Styrofoam coolers and makeshift shelves won’t cut it if you care about lab safety and product integrity.

Air and Moisture: The Enemies in Disguise

Every time the bottle gets opened in an open room, you lose a little product—and add a little risk. Moisture in the air starts a reaction you won’t always see coming. Sealed glass bottles lined with Teflon or polyethylene make life easier. These liners block the sneaky humidity that finds its way through regular caps. Some labs use desiccators with silica gel, but forgetting to recharge the gel turns a good practice into a pointless ritual.

Poor Ventilation, Real Consequences

One thing that gets overlooked: fumes can escape during even routine use. Inhalation hazards grow worse when a storage closet lacks exhaust fans. Chemical fume hoods, or at least a well-ventilated area set aside just for reactive chemicals, set a baseline level of safety. I’ve watched people get careless and cough through an entire afternoon because proper airflow took a backseat to convenience.

Labeling and Accountability

Every bottle deserves clear, unambiguous labels. Relying on memory or makeshift sticky notes is the start of an accident story. Labels should spell out hazards, dates received, and the exact content. If dark glass is available, all the better—some chemicals drift faster under light. An up-to-date inventory can seem tedious, but missing dates or misidentification risks the next batch going off unexpectedly. Lab managers earn their keep by insisting records match reality, not wishful thinking.

Legal Basics Aren’t Enough

Regulatory bodies like OSHA and REACH step in with baseline storage instructions—store in tightly closed containers, reduce possible exposure, check MSDS sheets. These are minimums, not high standards. Insurance claims and health inspections follow the letter of the law, but families and coworkers count on habits that go beyond compliance. Fire doors, spill response kits, and emergency eyewash stations matter. True safety depends on how seriously staff brings these to life, training new hands before problems show up.

Solutions Rooted in Responsibility

Buying proper storage cabinets, investing in training, and routinely checking for outdated or leaking containers turn what can be a dangerous material into an everyday non-issue. No one likes paying for infrastructure, but the cost of mishandling far outweighs the upfront investment. The lesson stays simple: respect the material, and no surprise ends up waiting for you tomorrow.