5-Bromo-2-Chlorobenzoic Acid: Context, Properties, and Impact

Historical Development

Back in the 20th century, chemists scouring the world of halogenated benzoic acids discovered unique behavior from compounds containing two reactive halogen atoms. This led to systematic studies on derivatives like 5-Bromo-2-Chlorobenzoic Acid—a chemical that found its feet in research labs on the promise of pharmaceutical and agrochemical advancements. German chemists often drove early synthetic routes, searching for better yields and cleaner reactions. They didn’t chase patents just for the paperwork; research was often shaped by what could be done reliably on a laboratory bench. Repeated syntheses, literature reviews, and cross-continent debates on substitution reactions fed into a small but persistent trickle of papers, patents, and process improvements.

Product Overview

The market for 5-Bromo-2-Chlorobenzoic Acid centers around its role as a building block. Manufacturers support both large and custom orders, offering both reagent grade and industrial versions. Commercial demand mainly comes from pharmaceutical companies and academic researchers who explore the structure and reactivity of halogenated aromatics. Sales data from chemical suppliers over the last five years tells a story: not a blockbuster, but persistent requests make it a staple in catalogs. Its catalog presence goes back decades, and it has gained more attention as interest in halogen-containing intermediates increases.

Physical & Chemical Properties

5-Bromo-2-Chlorobenzoic Acid forms off-white to pale yellow crystalline solids at room temperature. The compound shows high melting point stability, usually between 180-184°C, thanks to strong intermolecular forces. It resists dissolving in cold water but mixes well with organic solvents like DMF or DMSO—important for synthetic chemists planning multi-step reactions. Analytical chemists often use proton NMR, infrared spectrometry, and high-resolution mass spectrometry to confirm its identity, noting the characteristic signals from aromatic hydrogen atoms and the specific shifts for bromine and chlorine attachments. Stability tests have shown resistance against mild acids and bases, while exposure to strong reducing agents changes its chemical nature.

Technical Specifications & Labeling

Chemical producers stick to tight technical sheets. Purity usually guarantees ≥98% based on HPLC. Impurities—often derivatives formed during bromination or chlorination—rarely top 1%. Packaging comes in brown glass or high-density polyethylene to keep the material dry and away from light. Labels carry hazard icons, batch numbers, expiry dates, and recommended storage conditions (2-8°C). Most suppliers also include lot-specific certificates of analysis, following ISO and Good Manufacturing Practice (GMP) standards, not just regulatory checkboxes.

Preparation Method

Synthesis kicks off by brominating 2-chlorobenzoic acid, but the process needs careful cooling and a slow addition of bromine to keep reaction conditions controlled. Standard laboratory routes use iron catalysts to direct bromination to the correct position (position 5). Industrial-scale production, on the other hand, gears toward greener chemistry, leaning on lower solvent volumes and improved catalyst systems to minimize waste. Several patents outline slurries, crystallization, and purification through recrystallization or chromatography. Recovery of unreacted starting material gets prioritized to reduce costs—a lesson learned the hard way by process chemists chasing higher yields.

Chemical Reactions & Modifications

Chemists run a range of transformations starting with this acid. Common strategies include conversion to amide, ester, or anilide derivatives since the carboxylic group offers a natural handle for coupling reactions. The presence of the bromine atom at the meta-position and chlorine atom at the ortho-position tunes the reactivity of the aromatic ring, favoring selective cross-coupling reactions. Suzuki and Buchwald-Hartwig couplings both work efficiently, giving access to substituted biphenyls and diaryl amines. Pharmacologists often attach fragments to the acid’s core for drug candidate libraries, reflecting its value beyond the small-molecule world. Every reaction has its learning curve; the halogenated substrate sometimes surprises with side reactions if temperature controls lag.

Synonyms & Product Names

In labs and commerce, this compound comes under several names: 5-Bromo-2-Chlorobenzoic Acid itself, 2-Chloro-5-Bromobenzoic Acid (swapping substituent order), and sometimes coded catalog entries like B0791 or CBZ-25233 depending on the supplier. European and Asian chemical databases track the material under standardized registry numbers, but most researchers refer to it by the standard IUPAC name for clarity. A quick search pulls up synonyms in academic papers, supplier catalogs, and customs import records, all reflecting a long tail of consistent usage.

Safety & Operational Standards

Workplace safety protocols demand respect for halogenated materials, even if toxicity remains manageable by industrial standards. Chemists handling 5-Bromo-2-Chlorobenzoic Acid suit up with goggles, nitrile gloves, and lab coats. Most risk comes from dust inhalation or contact irritation, so weighing and dispensing often happens in fume hoods. Safety Data Sheets highlight standard precautions—avoid inhaling powders, wash thoroughly after handling, and store in cool, dry conditions. Waste disposal follows local guidelines for halogenated organics, reflecting a global trend towards improved environmental stewardship. Emergency eye wash stations and spill kits stay close; safety in real labs never gets delegated entirely to documentation.

Application Area

Pharmaceutical research uses the acid as a stepping stone in anti-inflammatory and anticancer compound synthesis. Agrochemical companies also build on the core structure to develop fungicides and herbicides. Academic labs focus on structure-activity relationship studies, probing the influence of halogen distribution on biological activity. Some material science teams use its stable structure to explore surface coatings and organic semiconductors. These uses trickle down to patent filings and journal articles, quietly shaping innovations in crop protection and potential new medicine.

Research & Development

Years of academic and industry publications push the boundaries of halogenated benzoic acid chemistry. Recent papers explore milder reaction conditions, photoredox catalysis, and solvent-free techniques to bring down environmental impact. Collaboration with university spin-offs feeds into small-molecule drug discovery, where every new chemical transformation becomes a tool of competitive advantage. Conferences like ACS and IUPAC host presentations tracking the path from bench-scale syntheses to animal model studies. The willingness of researchers to share positive and negative results shapes a healthy, iterative growth in knowledge and process refinement.

Toxicity Research

Lab safety hinges on understanding the limits of chemical exposure. Toxicology studies flag moderate acute toxicity through oral and dermal routes, mostly in rodent models. Sensitization risk is present but not remarkable compared to less substituted benzoic acids. Fish and aquatic toxicity becomes a bigger concern, prompting chemists to manage effluent and invest in improved waste treatment. Regulatory agencies rely on wide testing—LD50 values, skin and eye irritation rates, and chronic exposure data—all reflected in global chemical safety databases. Many studies are ongoing, reflecting the drive to quantify not just occupational but environmental impacts as downstream use increases.

Future Prospects

Halogenated benzoic acids always find themselves up for revaluation with every new wave of environmental and pharmaceutical regulation. The push for greener synthesis and more sustainable production can bring newer catalysts and fewer solvents into play, trimming cost and waste. Research funding will chase modifications that make the acid more biologically active or less persistent in the environment. As AI-driven design tools become standard in chemical research, libraries built from 5-Bromo-2-Chlorobenzoic Acid derivatives will keep expanding. Watch for increased production driven by innovations in agriculture and medicine—two sectors where chemical building blocks rarely go out of style. If the past few decades are any guide, this acid will keep showing up behind the scenes, shaping real advances, even if most people never notice its presence.

Where 5-Bromo-2-Chlorobenzoic Acid Shows Up in the Real World

5-Bromo-2-chlorobenzoic acid, with its combination of bromine and chlorine atoms on a benzoic acid framework, looks simple at first glance. Its impact stretches far, though, past just a chemical formula on a lab shelf. After seeing how research and industry use this compound, it’s clear that its value comes from versatility—not just shelf life or purity.

Building Block in Pharmaceutical Research

A lot of pharmaceutical chemists reach for 5-bromo-2-chlorobenzoic acid when they want to make new drug molecules. Its structure acts like a Lego piece that connects to other molecules, helping researchers create more complicated chemical designs. These benzoic acid derivatives often become part of key steps in forming biologically active compounds. Drug development needs materials that can be customized easily during synthesis, and this acid’s reactive functional groups fit that bill.

Data from patents and scientific articles confirm that many antiviral, antifungal, and anticancer screening projects start their process with this acid as a backbone. Some companies apply it in the early research phase to make sure their target compounds end up with the right shape or solubility. Each time a team tries to improve a drug molecule’s performance—faster absorption, for example—this acid, with halogens ready to swap, opens doors.

Raw Material for Agrochemical Innovation

Demand for better crop yields keeps growing. 5-Bromo-2-chlorobenzoic acid serves as a starter molecule for agrochemicals, such as herbicides and pest repellents. Agrochemical manufacturers often need to tweak tiny aspects of a product’s chemistry to manage how it breaks down outdoors, or how selective it is at targeting weeds but leaving crops unharmed. This acid brings both flexibility and stability, letting researchers try out different structures without starting over from scratch. When seasons bring new diseases or resistant bug strains, starting with an adaptable ingredient like this can speed up development.

Chemical Synthesis and Dye Creation

Some of the brighter dyes and specialty chemicals in the textile and plastics sectors start with benzoic acids like 5-bromo-2-chlorobenzoic acid. Manufacturers rely on predictable reactions: the bromine and chlorine enable further attachment or substitution steps, letting chemists steer the color, fastness, or solubility of the dye. Years ago, I heard from a textile technologist who said even a slight change in dye molecule structure could help a batch of cloth hold color longer or repel stains.

Safety and Environmental Role

5-Bromo-2-chlorobenzoic acid demands careful storage and handling since halogenated benzoic acids tend to carry toxicological risks that don’t usually show up until you scale up production. Recent years have seen stricter environmental checks for such intermediates, especially in Europe and North America, so disposal and containment systems matter a lot. Plants that handle it put extra focus on closed systems and scrubbers to keep emissions low, and workers need ongoing training. This stricter oversight comes from lessons learned over time; missteps in balancing productivity and safety never end well.

Pushing Better Practices in Chemistry

Pursuing green chemistry—designing safer chemicals and using fewer hazardous reagents—has become a real priority for many labs using 5-bromo-2-chlorobenzoic acid. Some researchers now aim to recycle solvents or refine protocols to reduce hazardous waste and lower both environmental and workplace risks. This approach reflects what’s happening throughout the chemical industry: a drive for better stewardship without slowing research.

The compound remains essential in labs and industry plants alike, but its story keeps evolving with new science and a stronger push for safety and sustainability.

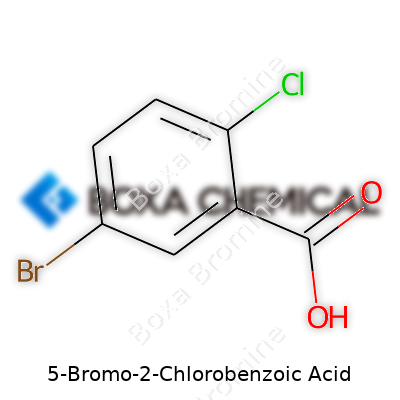

Chemical Formula and Structure

5-Bromo-2-chlorobenzoic acid isn’t a compound people encounter daily. Its chemical formula is C7H4BrClO2. Each part of this formula tells a story about its structure—a benzene ring at the core, carrying a carboxylic acid group, one bromine atom, and one chlorine atom, attached at specific positions. This arrangement shapes its chemical personality. With a molecular weight of 235.46 g/mol, it tips the scale a bit more than related benzoic acids, mainly due to those heavy halogen atoms.

Why Structure Means Something

The reason this compound matters boils down to function. In the lab, the replacement of specific hydrogens on the benzene ring with bromine and chlorine changes both the physical and chemical properties. That opens doors in making advanced materials, designing pharmaceuticals, and helping researchers create new molecules through targeted reactions. The hefty bromine and chlorine atoms do more than just weigh things down— they influence how the compound reacts. Under my own lab hood, I’ve seen how that can make or break a synthesis. Halogen substitutions shift reactivity in unique ways, making selectivity possible where it would otherwise be a hassle.

Health and Safety Concerns

Working with benzoic acid derivatives takes experience; throw halogens into the mix and the stakes go up. Both bromine and chlorine atoms don’t just add weight—they can change toxicity and environmental impact. It’s no secret that halogenated aromatics sometimes turn up in studies of persistence and bioaccumulation. Responsible work with these compounds means proper ventilation, gloves, and disposal, not a corner to cut. Safety protocols draw from real-world incidents, not from a rulebook. Years in the lab have made it clear: vigilance beats shortcuts every time.

Where It’s Used and Why That’s Worth Noting

Not every benzoic acid derivative lands in medicine cabinets or on manufacturing lines. Still, 5-bromo-2-chlorobenzoic acid has its place. In chemical libraries, it helps test new reactions. Medicinal chemists use it to tweak biological activity in drug leads. The electronics world can turn to similar compounds for making specialty materials. Even though this one isn’t a household name, the role it plays helps move research forward. Finding the right building blocks speeds up discovery and leads to new products, sometimes in unexpected fields.

Room for Better Solutions

If science has a recurring theme, it’s improvement. There’s always room to make the chemistry safer, the waste less harmful, or the process more efficient. Green chemistry isn’t just buzz—it’s a necessity. Alternative routes to make these benzene derivatives without dangerous reagents deserve more attention and funding. Some labs now use electrochemistry or catalytic methods that cut down on hazardous waste. By picking smarter routes, chemists protect both themselves and the environment—a lesson that sticks long after classes end.

Looking Forward

Every compound—no matter how niche—offers a lesson. 5-Bromo-2-chlorobenzoic acid stands as a reminder of how specific structures guide entire industries and shape day-to-day lab life. Understanding its formula and molecular weight gives a foothold, but awareness of impact and responsible action keeps science moving in the right direction.

Why Proper Storage Matters

Folks in the lab know 5-Bromo-2-Chlorobenzoic Acid for its role in synthesis projects, pharmaceuticals, and material sciences. Ask any chemist, and they’ll say a compound's reliability often depends on simple storage habits: wrong conditions can make things unpredictable, and that’s the kind of surprise nobody enjoys.

Safe Storage — Not Just Common Sense

Many chemicals don’t show their trouble until it’s too late. From my college days, one leftover bottle stored loose in a humid spot ended up caked with yellowish lumps instead of a white powder. Fumes ruined the label too. So, the first rule is clear: use an airtight, chemically-resistant container. Glass works best. Don’t let the powder or granules sit exposed to air, because moisture starts breaking things down.

Keep the bottle out of direct sunlight. Ultraviolet rays can do more than just fade labels: they can speed up chemical degradation. I always kept sensitive bottles in a cupboard that never saw a sunbeam or a heat vent. That kept the shelf life solid, and headaches away. Aim for storage at room temperature. A steady 20–25°C usually covers it for benzoic acid derivatives, including this one. Refrigerators aren’t necessary unless you have explicit supplier instructions to chill things.

Don’t forget about fire hazards. 5-Bromo-2-Chlorobenzoic Acid isn’t wildly flammable, but strong oxidizers in the same cabinet ratchet up risk. Never stack it next to nitric acid, peroxides, or other oxidizing agents. Segregating by hazard class saves time and accidents down the road: I’ve seen more than one lab get a visit from safety inspectors for mixing storage rules. Stick with a cool, dry, and well-ventilated space just for organics and keep containers sealed.

Handling: Don’t Get Casual

Direct skin contact with fine powders always irks me. With a halogenated compound like this, respect your gloves—nitrile works fine—and wear protective eyewear. During one project, someone dropped a scoop and tried to pick it up bare-handed. Ended up with skin irritation, plus a lot of paperwork for an exposure report. Use a fume hood, because even a little dust can be unpleasant. Most exposure problems start not with giant spills but careless scooping or pouring.

Never eat, drink, or store food anywhere near your chemical supplies. I once worked with a fresh grad who left a water bottle right next to a bench with open chemicals. Mistakes like that are easy to avoid and can keep you and your team out of the ER. Label your containers with the chemical name, date of receipt, and hazard information. Too many unmarked jars means too many mysteries—a problem shared by labs in industry and academia alike.

What To Do If Things Go Wrong

Spills? Don’t sweep or scoop them directly—wear gloves, and use a damp towel or cloth for small amounts, followed by proper disposal in chemical waste containers. For larger spills, get help from your safety office. Eye or skin contact means rinse with water for at least 15 minutes and get checked out. It feels excessive at times, but skipping steps cost colleagues dearly in the past. Never pour leftovers down the sink; follow hazardous waste disposal rules laid out by your local guidelines.

Building Trust Through Responsible Science

Chemical safety isn’t just about ticking off requirements. People who stay diligent end up saving others’ time, money, and trouble. Storing and handling compounds like 5-Bromo-2-Chlorobenzoic Acid with respect keeps projects running smoothly and everyone healthy. We all learn from a few close calls, but no one needs to learn the hard way if the basics get followed every day.

Understanding the Risks

People sometimes look at chemical names like 5-Bromo-2-Chlorobenzoic Acid and assume it’s business as usual, just another bottle on the shelf. Experience tells me it pays to take these names seriously. This compound doesn’t set off every alarm like some of the deadlier substances, but it doesn’t mean ignoring common sense is an option. Inhaling its dust or vapors can irritate the nose, throat, and lungs. Getting it on your skin can spark rashes and redness. Eyes are especially unforgiving — even small dust particles can cause burning and discomfort. Swallowing it? That’s a trip to the doctor you’d rather not have.

Why Safety Matters

Chemists always talk about “routes of exposure.” In a cramped lab or a plant with busy shifts, stories spread. No one enjoys cleaning up after a spill or worrying over a cough that wasn’t there before. Handling organohalogen compounds like this one teaches respect quickly. As it moves from inventory to benchtop, the biggest danger lurks not in dramatic reactions, but through slow, repeated exposure. R&D folks, students, and production workers have told me about minor accidents — skin contact, splashes, and a lingering chemical smell after a long day. Over time, breathing in particles or letting the powder touch bare hands can bring about health trouble, even if the label lacks a skull and crossbones.

Practical Safety Measures

Work starts long before the first scoop of powder. Reading the safety data sheet (SDS) gives you a real sense of what to expect. I always check for advice on ventilation, proper clothing, and storage. In practice, the best tool is self-protection. Wearing nitrile gloves and a fitted lab coat is non-negotiable. Safety goggles shield the eyes from airborne dust. If your work involves dumping, weighing, or transferring the compound, a dust mask or a properly rated respirator cuts down inhalation risk.

Lab ventilation isn’t just an architectural feature. Working in a fume hood makes a difference. Each time I’ve stuck to the fume hood, accidental exposure drops off sharply. You don’t smell strange odors, and any powder stays contained. Cleaning up right away with proper chemical wipes — not old paper towels — keeps residues from sticking around. I’ve seen labs where people neglect this simple step and pay for it later with accidental headaches or weird skin flare-ups.

Stories about chemicals corroding regular shelves aren’t just scare tactics. Storing 5-Bromo-2-Chlorobenzoic Acid in sealed, labeled containers avoids cross-contamination with other organics or bases. I always watch labmates pull from the wrong shelf, or put bottles back hastily after hours, and it only increases risk. At home, you lock the door; at work, you cap every chemical like your job depends on it.

Solutions to Stay Safe and Productive

Clear emergency plans aren’t just for big spills or fires. Every lab needs well-marked eyewash stations and showers. Quick response keeps minor disasters from turning into serious injuries. Training sessions — the hands-on kind, not endless slide decks — go further in helping new staff avoid rookie mistakes with 5-Bromo-2-Chlorobenzoic Acid or any compound. Regular reminders work better than written policies gathering dust in a binder.

Keeping up with personal hygiene rules matters more than people admit. Washing hands with soap every time before a snack or before heading out after a long experiment builds healthy routines. If a spill happens, washing the contact area right away prevents deeper issues. Other folks in the lab learn by watching, not by reading bulletins.

Handling specialty chemicals brings a responsibility to understand both immediate and long-term risks. Each piece of equipment, label, and protocol forms a real barrier between safety and hazard. Cultivating respect, not just caution, keeps accidents to a minimum and everyone healthier at work.

PURITY LEVELS DEMAND ATTENTION

Stepping into a lab and grabbing a reagent off the shelf, the first thing I check is the purity. Impurities waste time, sometimes money, and always patience. 5-Bromo-2-Chlorobenzoic Acid stands as a staple for people exploring aromatic synthesis or fine-tuning agrochemical intermediates. Purity marks the dividing line between a successful project and a series of confusing results.

Right now, most reliable suppliers offer purity levels at 98% and 99%, sometimes with certificates of analysis to back up those numbers. HPLC and NMR typically confirm this. From my experience, ultra-high purity—over 99.5%—rarely shows up unless requested for specialized pharma or electronics work. Impurities at even 1% can throw synthetic reactions off-track. In one project, a colleague switched suppliers due to persistent side products only to learn their original bottle contained less than 97% active content. Lesson learned: verify every time.

Low-quality batches sometimes show faint yellowing or moisture pickup, hinting toward hydrolytic breakdown or improper storage. Any off-color signals more than a cosmetic concern—sometimes, it signals reactive contaminants that create byproducts or catalyst poisoning. Keeping an eye on both documentation and material appearance supports product quality from bench to pilot scale.

PACKAGING PRACTICES IN PRACTICAL SUPPLY CHAINS

Packaging for 5-Bromo-2-Chlorobenzoic Acid isn’t just a logistics afterthought. It shapes shelf life, minimizes wastage, and helps maintain purity. Smaller laboratories, like many I’ve worked in, mainly buy in 25-gram or 100-gram amber glass bottles. These work well in research, let you scoop out just what’s needed, and slow down any light-triggered degradation. For kilo-scale or pilot runs, suppliers usually provide 500-gram, 1-kilogram, or sometimes up to 25-kilogram fiber drums with double-layer polyethylene liners. I’ve seen problems when the inner bag tears, so I always recommend checking for secondary containment if the drum contents are valuable or moisture-sensitive.

Packaging impacts more than convenience. Small bottles cut down on air exposure and allow for clean handling, which matters when splits in large containers introduce dust or repeated scooping. Single-use packaging adds cost but makes sense for high-purity, low-volume applications. From watching production chemists over the years, the best results come from packaging right-sized for batch scale and labeling that lists lot number, packaging date, and storage advice.

ADVANCING QUALITY AND REDUCING SUPPLY ISSUES

Supply chain disruptions throw wrenches into day-to-day plans. Relying on just one source feels riskier every year. When budgets allow, it pays to vet two or three suppliers, cross-checking not only purity guarantees but packaging formats. Some fail to update documentation, or send drum shipments without secondary containment, and that ends up eating into already tight margins. Connecting with peers and scouring review sites helped my teams sidestep several near-misses with poor batches.

One solution stands out: tighter cooperation with vendors. Asking for batch samples and reviewing third-party analyses safeguards results. Transparent sourcing, good communication, and robust shelf-life data form the backbone for dependable research and manufacturing. As regulatory focus sharpens on trace impurities, the push for better packaging and honest purity reporting will only strengthen.