4-Bromobenzaldehyde: A Deep Dive into an Important Chemical

Historical Development

4-Bromobenzaldehyde started showing up in literature in the early days of organic chemistry, alongside the rapid expansion of aromatic compound research. Researchers in the early 20th century looked for new ways to modify benzene rings, and the slow introduction of halogen substituents like bromine gave birth to a whole class of versatile starting materials for drugs, dyes, and specialty chemicals. Older synthetic methods often lacked precision, and early chemists dealt with unwanted isomers or tedious purifications. Improvements came as particularly sharp minds turned their attention to regioselectivity and greener halogenation methods. This compound became a mainstay in university laboratories as research in pharmaceuticals and materials sciences called for reliable building blocks that could be transformed in many ways.

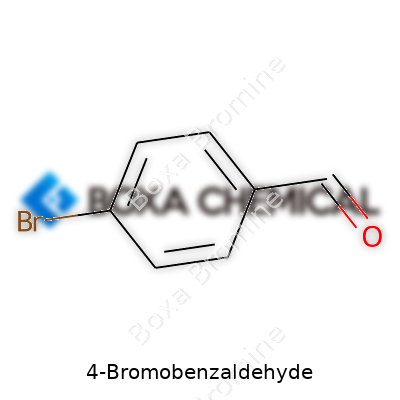

Product Overview

4-Bromobenzaldehyde serves as a key intermediate for synthesizing a range of advanced organic molecules. Labs buy it in crystalline or powdered form, typically packed in amber bottles for stability. Industry relies on it for its reactive aldehyde group and the electron-withdrawing bromine atom at the para position, which together offer many direct and indirect transformation routes. From experience, opening a bottle fills the lab with that sharp, slightly sweet odor common to simple aromatic aldehydes—a reminder that even small molecules can be potent.

Physical & Chemical Properties

This compound forms pale yellow to off-white crystals, melting between 53°C and 57°C. It dissolves in common organic solvents like ethanol, ether, and chloroform but shows poor solubility in water. Its molecular formula, C7H5BrO, delivers a molecular weight of 185.02 g/mol. The reactivity reflects a blend of the aldehyde group’s love for nucleophilic attack and bromine’s tendency to lend itself to substitutions. In chromatography, it elutes at moderate polarity and gives a single sharp spot on TLC in most solvents. Storing it in tightly sealed containers, away from light and moisture, preserves quality for years.

Technical Specifications & Labeling

Any reputable supplier provides 4-Bromobenzaldehyde with a purity above 98%, usually accompanied by detailed certificates of analysis listing melting range, GC-MS or NMR spectra, and trace impurities. Labels carry CAS number 1122-91-4, molecular formula, signal word ‘Warning’, and precautionary statements about inhalation and handling. In industrial settings, proper barcoding and lot tracking allow traceability, vital not just for quality but for safety audits. Laboratories keep original supplier labels visible, ensuring easy identification for everyone in the workspace.

Preparation Method

Experienced chemists prepare 4-Bromobenzaldehyde mainly by electrophilic aromatic substitution, starting with bromination of benzaldehyde or controlled formylation of bromobenzene. The benzaldehyde route involves adding bromine dropwise under cooled conditions to prevent polysubstitution, followed by quenching and crystallization. Catalysts like iron(III) bromide help nudge the bromine into the para position. Cleaner, greener methods now replace harsh oxidants with milder agents and avoid excess waste. On a larger scale, flow chemistry brings better heat transfer and more control, avoiding the runaway reactions once common in small flasks.

Chemical Reactions & Modifications

In the hands of a skilled organic chemist, 4-Bromobenzaldehyde turns into a powerful building block. Its aldehyde can join amines in Schiff base formation or undergo reduction to the corresponding alcohol. Nucleophilic substitution at the para-bromine allows coupling with amines, phenols, or organometallics. Suzuki-Miyaura cross-coupling opens the door to biaryl systems, while the aldehyde ensures continued reactivity for multi-step synthesis. These reactions form the backbone of drug discovery campaigns, polymer design, or dye synthesis. It’s a pleasure to watch the progression on TLC as each transformation gives crisp spots and strong UV activity.

Synonyms & Product Names

You’ll see 4-Bromobenzaldehyde in catalogs under several names: p-Bromobenzaldehyde, para-bromobenzaldehyde, and Benzaldehyde, 4-bromo-. Researchers use the IUPAC designation outside casual lab talk. Trade suppliers keep the synonyms in parentheses to avoid confusion. International shipments sometimes require harmonized naming in shipping documentation for compliance.

Safety & Operational Standards

Workplace safety circles back to the sharp smell noticed during handling. This compound irritates eyes, nose, and throat on inhalation and can cause dermatitis after skin contact. Laboratory best practice insists on gloves, safety goggles, and use of fume hoods. Spills call for immediate cleanup with absorbent pads—no one likes coming back to a sticky benchtop or persistent odors. Safety Data Sheets warn about combustion, encouraging dry storage and avoidance of strong oxidizers. Modern labs audit their protocols regularly, baking in safety culture through training and incident reviews.

Application Area

Drug development leans on 4-Bromobenzaldehyde to introduce new functional groups onto aromatic rings—the starting point for many CNS or cardiovascular agents. Material scientists employ it in the design of liquid crystals, dyes, and specialty polymers due to its blend of reactivity and stability. The flavors and fragrances world occasionally explores it for unique aromatic notes, but toxicity and odor limit its use there. In the classroom, it offers a reliable introduction to organic transformations for advanced undergraduates. Its wide presence makes it a favorite in both discovery and scale-up settings.

Research & Development

For those working on next-generation pharmaceuticals, new protocols involving 4-Bromobenzaldehyde show up in high-impact journals every quarter. Synthetic chemists expand the menu of cross-coupling and formylation methods, targeting milder conditions and higher yields. Some groups take on the challenge of asymmetric modifications, reaching for specialized ligands and catalysts to tease out chiral aldehydes. Researchers rarely work in isolation—open data sharing and consortia help drive efficiency, but competition remains fierce. Machine learning now aids retrosynthesis planning, letting labs shave weeks off project timelines.

Toxicity Research

4-Bromobenzaldehyde’s health impacts push for careful study. Acute exposure can cause eye and respiratory irritation, and sustained skin contact produces rashes or inflammation. Toxicology teams test its metabolites in rodents, checking for systemic organ effects or genetic impacts, and regulators insist on detailed reporting before new uses roll out in consumer products. Most data suggest moderate acute toxicity and low bioaccumulation—sufficient reason for gloves and proper ventilation, not alarm. Environmental fate studies mark it as biodegradable under aerobic conditions, yet standard wastewater treatment holds it back from entering waterways in meaningful amounts.

Future Prospects

As demand grows for greener chemical processes, future research into 4-Bromobenzaldehyde focuses on bio-based production and safer halogenation techniques. Academic and industrial chemists look to replace toxic solvents with aqueous protocols or solid-supported reagents, trimming waste while improving scalability. Its utility in pharmaceutical and material science applications isn’t slowing down—new patents keep flowing as researchers find fresh markets or synthetic routes. Computational chemistry and automation let scientists predict reactivity with stunning accuracy, putting time once spent trialing conditions back into the hands of innovators. If history proves anything, the chemical’s reliability and versatility mean it’s sticking around in labs for years to come.

A Closer Look at 4-Bromobenzaldehyde

There’s something oddly satisfying about learning the specifics of a molecule’s structure. If you've ever worked in a laboratory or handled chemical catalogs, you know how one extra atom or group on a benzene ring changes everything about a compound’s behavior. 4-Bromobenzaldehyde is a perfect example of tweaked simplicity in chemistry. To truly get a sense of what this substance brings to the table, all you need is a grasp of its formula: C7H5BrO.

Building the Structure from Experience

I remember my first organic synthesis project—precursor selection drove me nuts, and it took hours to read through chemical structures to choose the right compounds. Take benzaldehyde, for instance; it’s a basic aromatic aldehyde, useful in tons of reactions. Throw a bromine atom on the para position (opposite the aldehyde group), and now you have something that reacts differently with nucleophiles, or stands out on thin-layer chromatography plates thanks to that heavier halogen.

One bromine atom may seem harmless, but it shifts electron distribution, changes melting points, and brings unique reactivity to the molecule. Chemists looking for a convenient way to modify aromatic rings will choose 4-bromobenzaldehyde over its unsubstituted cousin because that strategically placed bromine opens doors to further substitutions using classic coupling reactions.

Why Chemical Formulas Matter

C7H5BrO tells quite a story for those who can read it. Seven carbon atoms and five hydrogens build the benzene ring and the aldehyde function, with the bromine set at the fourth (para) position relative to the aldehyde. The formula isn’t just a dry label. Synthesis depends on knowing it inside and out. Imagine scaling up a reaction for a pharmaceutical intermediate—missing the bromine would mean wasted resources and safety risks.

That formula helps researchers anticipate the behavior of the molecule when planning oxidation, reduction, or substitution. It’s not just about the chemicals themselves. The hazards and handling required for brominated compounds set them apart from plain hydrocarbons or oxygenated aromatics. The formula serves as a guide for safe storage and appropriate disposal.

Troubles in Application

Every lab bench that handles brominated aromatics faces tougher conversations about safety. Bromine isn’t friendly—it’s toxic and persistent in the environment. I’ve seen researchers scramble for new ventilation systems to handle fumes. Plus, containing spills and segregating waste becomes part of daily work once you move from benign benzaldehyde to its heavier halogenated version.

Beyond safety, regulation keeps tightening. Countries have started cracking down on brominated intermediates that cross borders without clear destination, to reduce the risk of diversion into harmful applications. Chemical suppliers now label and track every batch more closely than before, which often translates into slowdowns in research and increased cost.

Thinking Ahead

Any chemist working with 4-bromobenzaldehyde learns fast—know your formula, respect the risks, and treat it with the care it demands. Finding greener substitutes or using catalytic alternatives comes up, especially when academic groups brainstorm ways to ditch halogens in favor of renewables. At the end of the day, being meticulous with chemical formulas like C7H5BrO isn’t just about chemistry. It’s part of a broader effort to build safer, smarter practices in every lab.

The Building Block Few Know

Take a look inside any chemistry lab or advanced manufacturing plant, and there’s a good chance you’ll spot a bottle marked "4-bromobenzaldehyde." The name doesn’t roll off the tongue, but behind it hides a starting material with big influence in pharmaceuticals, agrochemicals, and electronics. I remember the first time I worked with this compound as a student—the smell, the caution guiding every pipette movement, and how a tiny sample meant the start of something new, from cancer drug projects to crop protection trials.

Pharmaceutical Pathways

Drug makers often need aromatic aldehydes for more complex molecules. 4-Bromobenzaldehyde makes a perfect partner in syntheses leading to antidepressants, antitumor medicines, and other therapies that affect millions. If you picture medicines like aripiprazole, you’re looking at a whole family of drugs built on benzene rings tweaked just like this. The bromine atom opens up sites for selective reactions, which gives chemists better control, so the process wastes less material and energy. AstraZeneca and Pfizer chemists have documented synthesis routes where compounds like this speed up their testing pipelines. That efficiency has only grown more valuable with rising demand for new therapies.

Protecting Crops, Feeding People

Farmers may never see 4-bromobenzaldehyde in their toolkits, but agrochemical companies use it as a precursor for certain herbicides and fungicides. Over the past decades, pesticide resistance has cost billions in lost revenue and food waste. Chemists rely on this specific aldehyde to help build molecules that knock out weeds or fungal blights without harming crops. According to published field studies by Bayer and Syngenta, some benzaldehyde derivatives stop pests that would otherwise devastate soybean, corn, and cotton fields. Every season, farmers bet on these formulations to protect the food supply from unpredictable weather and pests.

Organic Electronics: Small Parts, Big Impact

Tech companies searching for faster, lighter electronics have found new uses for aromatic aldehydes like this. Engineers use 4-bromobenzaldehyde to make organic semiconductors for next-generation displays and solar cells. During a research stint at a materials lab, I watched how tiny tweaks in these chemical building blocks turned ordinary plastics into materials that move energy or light almost as well as silicon. Cutting weight and cost means more affordable screens, lighter laptops, and flexible devices that really do survive a drop on the kitchen floor.

Safer Pathways and Environmental Focus

Many chemical makers face pressure to produce smarter, safer, and greener. Stringent regulations from agencies like the EPA and Europe’s REACH have forced a close look at starting materials. 4-Bromobenzaldehyde offers clear pathways for selective reactions, so fewer side products go to waste streams. Over the past five years, journals like Green Chemistry have published studies showing newer methods for making this compound, such as biocatalysis or controlled bromination, slicing hazardous byproducts and energy use. The digitalization of chemical supply chains now allows tracking every batch back to its source. I’ve seen younger chemists increasingly advocate that their employers use greener manufacturing—not just because the law requires it, but because everyone wants a safer lab and a healthier world.

Moving Forward: What Counts

Innovation never stops. 4-Bromobenzaldehyde’s place in new drug leads, plant protectants, and electronic materials shows just how chemical basics ripple through everything we rely on daily. Safer, sustainable manufacturing and open research partnerships could unlock even more breakthroughs down the road. For anyone who cares about new medicines, more resilient food systems, or better gadgets, tracking advances in these foundational materials makes all the difference.

Getting the Chemistry Right

I remember feeling lost the first time I stepped into an organic chemistry lab. Every bottle lined up on those shelves, each with a long, tongue-twister name. Among those, 4-Bromobenzaldehyde seemed just another chemical, but as I learned, even its molecular weight carries some serious weight in the lab. This isn’t just a textbook number—it's the backbone of calculations behind yields, dosages, safety margins, and even environmental disposal. Precision counts.

Breaking Down the Math

4-Bromobenzaldehyde carries the formula C7H5BrO. Let’s do the math:

- Carbon (C): 7 atoms × 12.01 g/mol = 84.07 g/mol

- Hydrogen (H): 5 atoms × 1.01 g/mol = 5.05 g/mol

- Bromine (Br): 1 atom × 79.90 g/mol = 79.90 g/mol

- Oxygen (O): 1 atom × 16.00 g/mol = 16.00 g/mol

Total: 84.07 + 5.05 + 79.90 + 16.00 = 185.02 g/mol

Why This Number Matters in Real Life

Anyone involved in chemical synthesis understands the headache of scaling up a reaction, only to discover that a small arithmetic error throws off everything. If the molecular weight is wrong, nothing lines up: reagents run short, yields disappoint, waste increases. That gets expensive—fast. Precision in chemistry protects researchers and consumers alike. In pharmaceuticals, for example, the amount used directly affects the dose a patient receives. Accuracy protects health and meets clear safety standards enforced by regulatory bodies, including the FDA and EMA. It’s not just about neatness—it's about trust.

Thinking Beyond the Numbers

Keeping data accurate depends on layers of good practice. Researchers checking suppliers for reputable sourcing, using certified analytical balances, double-checking inventory databases—these habits reduce risk. I’ve learned the value of cross-referencing. Check one good reference book, then confirm it with a reliable database. Most good labs do this as a matter of routine, but even hobbyists and small businesses should never skip this step. Sometimes numbers online get copied without verification, and once errors slip in, they spread.

Risk Reduction in the Laboratory

Much of lab safety hinges on starting materials and amounts. For 4-Bromobenzaldehyde, weighing mistakes caused by a faulty molecular weight can change reaction rates, trigger unwanted side reactions, or even create dangerous by-products. I have seen colleagues spend whole afternoons troubleshooting results, only to trace everything back to a data transcription error on a label. These moments stress the need for accuracy at every step, from ordering through disposal. Following strict routines, using up-to-date safety sheets, and regularly auditing chemical inventories go a long way to preventing small mistakes from becoming big problems.

Practical Steps Toward Better Chemistry

Numbers by themselves can feel abstract but, in the world of molecules, every digit matters. Triple-checking molecular weights before finalizing calculations can prevent a cascade of errors. Favorite sources include peer-reviewed chemical handbooks, Sigma-Aldrich technical documents, and resources like PubChem or ChemSpider. Back in the lab, clear labeling and digital tracking mean fewer surprises and safer projects. For teachers, spending time reviewing calculation steps with students pays off—errors caught in the classroom don’t transfer to critical real-world decisions.

Why Proper Storage Matters

Anyone who’s spent time in a lab knows chemical storage often gets overlooked until there’s a problem—moisture seeps in, labels fade, or a stray bottle triggers a surprise during inventory. 4-Bromobenzaldehyde sits in the class of aromatic aldehydes, and it’s used broadly in organic synthesis, especially in making fine chemicals, dyes, and pharmaceuticals. Mishandling even routine reagents causes shelf-life headaches, potential safety issues, loss of investment, and research delays.

Controlling the Basics: Temperature and Light

Heat speeds up all sorts of unwanted reactions. Every seasoned chemist stores 4-Bromobenzaldehyde below 25°C—room temperature tends to work for short-term storage, but lower temperatures slow down the chemical’s gradual degradation. I worked in a teaching lab early in my career, and too-warm storerooms led to yellow-tinged samples, especially in summer. Wrapping up containers and placing them in a cool cupboard prevented frustration.

Light isn’t friendly to many aromatic compounds. Sunlight and strong lab lighting trigger oxidation, which brings about odd side-products. Amber glass bottles and storage in dark cabinets go a long way for 4-Bromobenzaldehyde. This isn’t overkill; I’ve seen small labs trying to save money leave clear bottles on windowsills, and by semester’s end, nearly half their aldehyde supply needed disposal.

Keeping Out Air and Moisture

Aldehydes are notorious for reacting with oxygen in the air. 4-Bromobenzaldehyde, with its reactive formyl group, starts to oxidize and lose usefulness if exposed for too long. Good practice means tightly sealing containers after each use. My mentor always swore by parafilm to reinforce bottle caps—simple, cheap, and effective. Desiccators work even better for longer-term needs. Throwing in a silica gel packet protects the compound from humidity, which is especially practical during rainy seasons or in coastal areas.

Water doesn’t just spoil purity. Even trace amounts may drive hydrolysis, lowering yield and muddling spectral data. Students I trained regularly found that careless pipetting or leaving bottles open during weighing led to changed melting points and false negatives in quality control tests.

Safety and Labeling

Something easy to forget: 4-Bromobenzaldehyde isn’t just another bottle on the shelf. Inhalation or skin contact irritates, so chemical-resistant gloves and goggles should stay nearby, and the bottle itself should be kept in a well-ventilated part of the storeroom—ideally, a specific flammables or toxics cabinet, never next to food or water sources. I had a lab-mate accidentally mistake it for benzaldehyde due to faded handwriting, contaminating a synthesis batch for weeks. Fresh labels with proper chemical name, date received, and hazard rating clear up confusion, especially in group environments.

Staying Ahead: Inventory and Waste Handling

Rotating stock is more than bureaucracy; fresher chemicals mean predictable reactions. Regular checks prevent forgotten containers from degrading and potentially leaking. Any compound that changes color or emits unusual odors should leave the storeroom immediately, following local hazardous waste protocols. I’ve seen departments fined for improper oxidative aldehyde disposal, where a few extra minutes with logbooks could have saved real cash.

Better Storage, Better Chemistry

No need for expensive equipment—following these simple strategies protects both users and reagents. Careful control of temperature, exclusion of air and moisture, good labeling, and proper segregation ensure 4-Bromobenzaldehyde remains reliable for every reaction, every time.

Understanding the Risks of 4-Bromobenzaldehyde

Anyone who’s spent time around research labs or chemical manufacturing knows there’s a world of difference between handling a compound and understanding its quirks. Take 4-bromobenzaldehyde. With its pale, crystalline appearance, nobody would expect trouble at first glance. Yet appearances can be misleading.

This chemical carries a bromine atom stuck to an aromatic ring. That might sound like textbook jargon, but in practical terms, this structure makes the substance more reactive than plain benzaldehyde. Volatility and reactivity often walk hand-in-hand with hazards that don’t show up until someone gets careless.

Real-World Hazards That Can't Be Ignored

Anyone who’s popped open a bottle of 4-bromobenzaldehyde without proper gloves or goggles ends up learning a lesson the hard way. Skin doesn’t welcome this compound—even minor spills can leave irritation and stubborn redness. My old college lab partner once handled an open flask without a fume hood and spent the afternoon fighting off a persistent cough. The fumes, though not overwhelming, have a way of sneaking up during weighing or mixing tasks.

The story doesn’t stop with immediate symptoms. Inhalation or accidental ingestion could bring on headaches, nausea, and more severe discomfort, especially after repeated exposure. The eyes take the brunt; splashes sting and lead to redness that lingers longer than most expect. Agencies like the European Chemicals Agency have already flagged the compound for possible acute toxicity. This isn’t the stuff for casual tinkering.

Chemical Stability Does Not Equal Safety

Some chemicals go bad in sunlight or react explosively with air. 4-bromobenzaldehyde stays more stable than those, but it still belongs locked up and labeled. Spills or improper storage don’t just mess up results—they risk contaminating everything around. As somebody who’s handled close cousins of this compound, I can say that contamination in shared lab settings can take hours, or sometimes days, to sort out.

The Need for Special Handling Precautions

Standard operating procedures in the lab put this substance in the “handle with real caution” category. Gloves, goggles, and lab coats aren’t just for show. Good ventilation helps keep the air clean and those telltale odors at a minimum. I’ve watched plenty of seasoned researchers rely too much on chemical intuition, only to be caught out by the slow build-up of irritation over time.

Disposal creates another layer of challenge. You can’t wash this away down the drain or toss it in a regular trash can. Proper waste streams matter, and ignoring this fact only brings headaches from waste management later on. Institutions set up guidelines based on years of mistakes and lessons learned the hard way. It pays to trust that process.

Teaching Safer Laboratory Culture

New researchers often come in eager to experiment but short on respect for the hidden dangers of chemicals like 4-bromobenzaldehyde. Mentors and instructors have a duty to pass on more than just the technical steps; they set the tone for safe handling. Strong safety culture helps prevent injuries, protects research, and keeps everyone sane through long hours in the lab.

Trust in the safety data sheets and manufacturer guidelines pays off, as does reading up on regulatory updates. Labs handle more chemicals than ever, making awareness of each compound’s traits absolutely non-negotiable. Taking shortcuts with 4-bromobenzaldehyde rarely ends well for anyone.