2-Bromotoluene: A Comprehensive Commentary

Historical Development

The story of 2-bromotoluene starts in the laboratories of the late nineteenth century, with electrophilic aromatic substitution chemistry changing the landscape for organic synthesis. Chemists needed efficient ways to functionalize aromatic rings, and halogenated toluenes provided answers. Early on, 2-bromotoluene opened doors in dye manufacturing, as bromo-substituted aromatics guided the path for azo and anthraquinone dyes. The development reflected the push to tailor molecular structures for colorfastness and better yields—a practical need big enough to shape the future of chemical industries. It wasn’t limited to dyes, though; Dutch and German industrial chemists realized the value of bromoaromatics as steppingstones for more complex compounds, especially as pharmaceuticals and agrochemicals became part of everyday life. The molecule found its niche, quietly supporting advances behind the scenes, as chemists kept searching for better ways to make, modify, and understand it.

Product Overview

2-Bromotoluene, sometimes called o-bromotoluene, isn’t flashy on its own—a colorless liquid with a medicinal scent. Despite its simplicity, this compound enables serious chemical transformation. It works as both a finished product and a reagent, acting as a building block in the synthesis of pharmaceuticals, agricultural chemicals, and flame retardants. Lab shelves in both research and manufacturing settings often include a bottle of 2-bromotoluene, as the molecule’s ortho-bromo-methyl combination lends unique reactivity. Its importance shows up mostly through what it helps create; for me, the value became clear when I struggled to synthesize a specific benzyl-substituted product. Using 2-bromotoluene’s reactivity cut my work in half, reminding me that sometimes the simplest chemicals carry the most load in the shadows of bigger, more obvious breakthroughs.

Physical & Chemical Properties

2-Bromotoluene appears as a clear, oily liquid, with a boiling point around 180°C and a melting point below room temperature—this means it stays fluid under typical laboratory and industrial conditions. Its density tops 1.4 g/cm³, heavier than water, and it won’t dissolve in water but does blend with most organic solvents. The molecule owes much of its behavior to the bromine atom at the ortho position, next to the methyl group, on the benzene ring. With a molecular formula C7H7Br, the structure packs enough reactivity to invite both nucleophilic and electrophilic substitutions in later reactions. The compound’s refractive index and vapor pressure signal both purity and volatility, so careful handling matters to avoid loss and exposure. I learned early on to double-check containers for tight seals, as even a small leak can cloud a lab with its distinctive odor.

Technical Specifications & Labeling

Suppliers sell 2-bromotoluene with purities usually ranging from 98% to 99%. GC analysis accompanies most shipments, with assay values, evaporation residue, and water content close at hand. Catalog labels rely on identifiers like CAS number 95-46-5 and other international registration codes. Safety symbols mark the bottle—flammable, hazardous to the environment, and potentially irritating. Batch information points to traceability, an argument for accountability in any lab or factory. I’ve benefited from clear labeling more than once; correct hazard symbols and expiry dates have helped avoid mistakes, especially for students and newcomers scattered through the chaotic spaces of shared workrooms. Specifications matter not because perfection is possible, but because any doubt about quality can reverberate down long production lines or complex syntheses.

Preparation Method

Commercial production of 2-bromotoluene usually follows the bromination of toluene with molecular bromine, catalyzed by iron or another Lewis acid. Selectivity for the ortho isomer doesn’t come easy—statistical chances favor mixtures, since para-bromotoluene forms as a significant byproduct. Experienced chemists fine-tune temperature, solvent, and bromine feed ratio to swing the reaction toward the ortho product. In my time working with halogenations, temperature control made the biggest difference. Rushing the process or losing track of the exotherm multiplied unwanted isomers, forcing tedious separations. Careful engineering, though, wrings efficiency from the process and keeps downstream purification costs in check. For high-value products, crystallization and distillation refine the output, delivering material with minimal contamination—a necessity if the final product goes toward pharmaceuticals or electronic chemicals.

Chemical Reactions & Modifications

Reactive bromine on the aromatic ring makes 2-bromotoluene a versatile player. Suzuki and Heck reactions depend on bromoarenes like this to forge carbon-carbon bonds, connecting aryl and vinyl groups to produce biphenyls, stilbenes, and more. Nucleophilic substitution allows for the introduction of amino, cyano, and hydroxyl functionalities. In labs pursuing novel ligands or drug scaffolds, the methyl group offers a handle for oxidation, chlorination, or side-chain extension. Cross-coupling methods revolutionized aromatic chemistry, and 2-bromotoluene often acts as the starting point for synthesizing custom molecules. I’ve seen researchers improve yields in OLED and pharmaceutical ingredient work simply by using the right isomer at the right time—a lesson in chemistry’s dependence on subtle details and proper starting points.

Synonyms & Product Names

2-Bromotoluene answers to many names—ortho-bromotoluene, o-bromotoluene, 1-bromo-2-methylbenzene, and Benzenebromomethyl. Different suppliers and catalogs might pick one over another, but the CAS number remains constant. Sometimes, older literature uses less systematic terms, introducing minor confusion for students connecting textbook knowledge with lab practice. Consistent nomenclature doesn’t always spark excitement, but the headaches averted by clear synonym cross-references can hardly be overstated, especially for multinational procurement and collaboration.

Safety & Operational Standards

Exposure to 2-bromotoluene can irritate skin, mucous membranes, and the respiratory tract. Handling it with gloves, goggles, and a lab coat reduces risk, but good ventilation does more than most realize. Inhalation of vapor at high concentrations leads to dizziness and lightheadedness, with heavier vapor tending to pool in low-lying places. Storage follows the standard drill: cool, dry, tightly closed, and away from strong oxidizers. Facilities handling larger volumes require spill containment protocols and emergency eyewash stations; training staff to handle accidental releases can mean the difference between an inconvenience and a full-scale evacuation. Over the years, frequent near-misses drilled the need for respecting both the substance and the infrastructure that contains it. Keeping rigorous records and updating risk assessments isn’t bureaucratic excess—it’s a recognition born from experience.

Application Area

The reach of 2-bromotoluene extends into pharmaceuticals, agrochemicals, dyes, and specialty polymers. Its main task lies in serving as the precursor for more advanced building blocks. For instance, Suzuki coupling transforms it into biaryls used in non-steroidal anti-inflammatory drugs or certain antihistamines. Agrochemical engineers see value in its use to make fungicides and herbicides, especially where the bromine atom confers persistence and selectivity. In the world of electronic materials, 2-bromotoluene’s derivatives factor into OLED manufacturing and advanced plastics, where controlled substitution on the aromatic ring dictates final properties. From my side, the satisfaction comes in seeing a simple molecule spun out into products that touch people’s daily lives—not only in medicines, but in food production and screens on living room walls.

Research & Development

Research tied to 2-bromotoluene covers cleaner synthesis, more selective coupling reactions, and greener alternatives that trim waste and byproducts. Labs across the globe pursue catalyst designs that speed up reactions and reduce precious metal use. Smart sensor development draws on bromoaromatics’ unique optical and electronic properties, nudging chemists away from blunt trial-and-error toward data-driven exploration. R&D also targets reaction condition streamlining—solventless reactions, microwave-assisted setups, and flow chemistry all promise higher yields and safer working environments. Watching the science evolve from crude separation in glass columns to continuous processes in steel reactors gives a sense of how persistent, incremental tinkering can reshape an industry’s footprint.

Toxicity Research

Toxicology data for 2-bromotoluene tracks both short-term and chronic risks. Animal studies suggest low acute oral toxicity, but repeated exposure leads to liver and kidney stress. Inhalation studies document respiratory irritation and central nervous system depression at higher doses. Environmental studies show moderate persistence, with slow breakdown and potential to bioaccumulate. Though not flagged as an acute carcinogen, the compound faces careful regulation due to concerns over long-term health effects and environmental runoff. My time working alongside environmental scientists taught me that these concerns aren’t theoretical—runoff into waterways or mishandling of waste threatens ecosystems more than most single-lab accidents ever will. Mitigation means proper disposal, spill planning, and ongoing research into safer alternatives whenever feasible.

Future Prospects

The road ahead for 2-bromotoluene follows both tradition and innovation. Demand ties closely to downstream industries—pharmaceuticals, electronics, advanced materials—all still growing with increased customization of molecular products. Green chemistry will likely influence production, as manufacturers shift to renewable feedstocks, less toxic solvents, and recyclable catalysts. Digital process control and AI-guided synthesis pipelines offer tighter yield optimization, promising less waste at every step. Regulatory shifts responding to health and environmental impact will shape adoption, as stricter controls force alternatives and substitutions. At every level, the chemistry community faces the challenge of balancing efficiency and impact—drawing lessons from past excesses to guide more sustainable practices. The practical wisdom gained over decades of production, research, and application remains vital as we seek new pathways to the same reliable molecular workhorse.

A Push Forward in Chemical Manufacturing

2-Bromotoluene rarely makes headlines, but it serves as a key player in chemistry labs and production plants across the world. For years, I watched chemists and engineers lean on this compound without much fanfare. The molecule looks simple—just toluene with a bromine atom stuck in the ortho position. In practice, that small modification drives a lot of industrial processes.

Building Blocks and Bigger Pictures

You don’t run across 2-bromotoluene at the grocery store, but chemists know it well as a reliable starting point. The main draw comes from its ability to morph into other chemicals thanks to its bromine group. That element swaps out easily in chemical reactions, allowing researchers to attach something new at just the right spot. For instance, I’ve seen this in the lab, where 2-bromotoluene slides into Suzuki and Ullmann coupling reactions without fuss, opening up options for building all kinds of fine chemicals.

Agriculture, medicine, and materials science use these new molecules, many of them built from a foundation that includes 2-bromotoluene. Researchers create herbicides, fungicides, and active compounds all rooted in these transformations. As someone who’s relied on the consistency of intermediates, I respect how often this aromatic compound anchors the early steps in projects that eventually yield useful products.

The Link to Pharmaceuticals and Agrochemicals

In drug discovery, even minor tweaks to a molecule can shift its effectiveness or safety. Medicinal chemists often reach for 2-bromotoluene because it lets them introduce precisely the right groups to a new medicine. This precision saves time and money, not to mention lab stress. In production work, companies use it when making well-known pharmaceuticals and agricultural chemicals. A quick look at patent filings turns up dozens of examples linking this intermediate to compounds that treat infections or protect crops.

Engineered for Versatility

Large-scale production, especially in Asia and Europe, churns out 2-bromotoluene to meet regular demand. The process doesn’t require gold-plated equipment—just careful control, some patience, and years of experience with safe handling. Given the toxic nature of bromine and the fire risk from toluene, I learned early on not to cut corners. Modern safety standards and engineering controls now keep most of the acute hazards in check.

What matters is how many choices this molecule opens up for manufacturers. Instead of getting locked into one type of product, facilities can head off in almost any direction, pushing chemical synthesis into new territory. This flexibility gives them an edge in today’s fast-moving industries.

Looking for Greener Options

Chemical makers and researchers understand the pressure to clean up production. I’ve seen a shift in recent years toward greener chemistry, including better ways to make and use compounds like 2-bromotoluene. Teams focus on reducing waste and finding less-harmful reagents. Projects aiming for recycling bromine or swapping in catalytic alternatives are picking up steam—sometimes spurred on by tighter environmental regs and cost pressures.

2-Bromotoluene won’t end up in your medicine cabinet, but there’s a good chance it helped shape what’s inside. For many, it’s just another industrial material. To people who build things one molecule at a time, it stands as a dependable start, with an eye toward safer, smarter, and more sustainable chemical manufacturing.

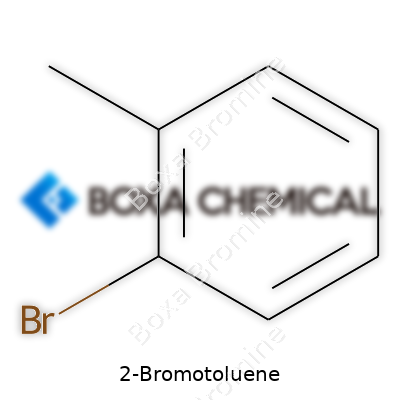

Chemistry Right on the Page: 2-Bromotoluene’s Makeup

Every so often, folks run into a chemical name that looks intimidating, but breaking down the structure gives some comfort. Take 2-Bromotoluene for instance. No need to be a seasoned scientist to get at what’s going on with this molecule. At its core, 2-Bromotoluene stands for a benzene ring with two attachments: a bromine atom and a methyl group. The positioning of these two groups—close neighbors on the ring—ends up mattering a lot, not just to chemists but also to people working in the real world, handling the stuff in labs and factories.

The Actual Formula and Structure

2-Bromotoluene’s chemical formula is C7H7Br. Whittle that down and you’ve got seven carbons, seven hydrogens, and a single bromine atom. The methyl group sits on the benzene ring, and so does the bromine atom; they both attach to neighboring spots, making it the “ortho” version in chemical terms.

I’ve seen this one pop up on molecular model kits: you plug in the pieces and it gets obvious—just a standard six-carbon benzene ring, with a CH3 and Br hanging off carbons next to each other. If you’re the hands-on type, building these out can really help make things click if you’re a visual learner.

Why the Formula Matters Beyond the Lab

A formula isn’t just a jumble of numbers and letters. It gives a snapshot of how the molecule behaves, both in nature and in industry. 2-Bromotoluene plays a role in synthesizing other chemicals: dyes, pesticides, pharmaceuticals, and even flavoring agents on occasion. It acts like one of those connectors in a LEGO set—vital if you want your next structure to stand strong.

Brominated aromatics, in my experience, need careful handling. That single Br atom adds heft to the molecule, changes its reactivity, and makes it a target for further chemical reactions. Its presence raises questions for safety and environmental monitoring. Given current knowledge around brominated compounds, any chemist with a conscience gears up with gloves and eye protection every time they reach for that bottle.

Relevance in the Modern World

Both the placement and type of atoms in a molecule control the paths it can take in chemical reactions. For manufacturers, predictability in structure means less waste, lower costs, and better output for whatever they’re making—whether it’s crop protection tools or specialty polymers. On the regulatory side, clear formulas help authorities keep tabs on what’s flowing through supply chains and into the environment.

Accidental spills or improper storage can put communities at risk. I’ve seen labs run drills and set up checklists just because a storage cabinet contained brominated aromatics. Knowledge of its makeup—C7H7Br—makes a difference in response time if an incident happens.

Direct Approaches to Safer Chemistry Use

Education forms the backbone for better chemical decision-making. Hands-on training, solid access to information, and a culture that backs up safety can shrink risks down to a minimum. Researchers keep looking for green chemistry alternatives, which means if a less hazardous substitute for 2-Bromotoluene comes along, industry can make the switch without missing a beat. Until then, awareness of what molecules like C7H7Br really are and how they act puts everyone a step ahead.

Why Safety Around 2-Bromotoluene Deserves Attention

Anyone who’s ever worked in a lab or a chemical plant knows the sharp smell that comes with many solvents and reagents. 2-Bromotoluene stands out, not just because of its use in organic synthesis, but also because of what can go wrong if you get careless. A small mistake—spilled liquid, an open bottle, unfiltered air—can lead to headaches, shortness of breath, or some ugly skin irritation. Most accidents happen when routine replaces vigilance.

Protecting Your Skin and Lungs

Latex or nitrile gloves and a full-sleeved lab coat protect skin. Even a drop of 2-Bromotoluene can cause redness or rash if touched. Splash-proof goggles knock out the risk of eye exposure, which is no small thing—I’ve seen an experienced tech rinsing their eyes frantically because they forgot to double-check their face shield. Chemical-resistant gloves, not just any pair, form your first defense. Nitrile gloves actually hold up well, and nobody should settle for less.

Working on an open bench without protection? That’s a recipe for exposure. Always use a fume hood—one that functions well and draws vapors away before anyone’s nose can register a scent. Vapor inhalation means nausea, coughing, and dizziness, and sometimes the effects stick around longer than expected. I’ve learned it’s always easier to avoid a problem than wrestle with an incident report or worry over long-term health.

Handling and Storage: Taking Control, Not Chances

2-Bromotoluene is flammable. Storing bottles far from heat sources and open flames makes sense, but don’t overlook the smaller things—sealed containers, tight-fitting lids, clean absorbent pads nearby. A locked, ventilated cabinet holds danger in check, especially if spill kits are right there, ready to be used. I once spotted a cracked cap on a storage bottle; just a few hours later, the lab stank and the supervisor spent half a day dealing with the aftermath. Prevention beats clean-up every time.

Many overlook labeling, but quick and clear labeling keeps the surprises away. Every container with 2-Bromotoluene ought to list its contents, hazards, and the date it entered the lab. People don’t often mix up their sugar with their salt at home—so why risk a mix-up in a chemical stockroom?

Disposal Isn’t Just an Afterthought

Some folks see waste as the last step, when really, it’s part of working safely. No one should pour 2-Bromotoluene down a drain. It goes into a properly marked hazardous waste bottle, separate from acids, bases, or anything likely to react. A few minutes spent reading a Safety Data Sheet helps, but knowledge only matters if it’s put to real use. In my own experience, clear protocols and a little accountability have prevented more accidents than any single piece of equipment.

Training, Habit, and Respect

People make the lab safe, not just gear or rules. Knowing your chemicals well, taking time to go through the right steps, and speaking up if something feels off—those habits protect everyone. No shortcut on training or oversight pays off in the long run. Safety isn’t about paranoia—it’s just a steady respect for what these compounds can do, both in science and to your own health.

Learning Through Practical Chemistry

The boiling point of 2-Bromotoluene lands around 222 to 224°C. That figure might seem like a simple laboratory stat, but the temperature at which a chemical transforms from a liquid to a gas often says a lot about its nature and its day-to-day handling. During my early research days, working with compounds like 2-Bromotoluene meant reading and re-reading safety sheets before ever popping open the bottle. Knowing the boiling point wasn’t just for satisfying curiosity—it meant choosing glassware that wouldn’t crack under the heat and picking the right containers to keep vapors in check.

Handling and Safety Concerns

A high boiling point sounds reassuring if you’re thinking spills will only evaporate slowly. The issue creeps in inside heated labs or industrial environments, where small temperature mistakes can fill a room with fumes. Vapors rising from 2-Bromotoluene carry both a recognizable odor and potential health hazards. The Centers for Disease Control and Prevention point out that aromatic halides like this one need solid ventilation and tight lid discipline. During all my time on chemical benches, I saw seasoned lab workers fix a vent hood in seconds if they caught a whiff—not just for comfort but because chronic exposure brings heavy risks.

Why Industry Cares About This Boiling Point

In the chemical manufacturing world, processes like distillation depend on sharp temperature control. Toluene-based compounds get split and purified using differences in boiling points. 2-Bromotoluene’s spot at 222–224°C lets it slot in for certain syntheses when chemists want the reactivity of the methyl group but the selectivity of a halide. Those extra twenty degrees compared to ordinary toluene change the entire workflow when trying to separate, recover, and reuse other ingredients.

Quality, Purity, and Environmental Impact

Impurities influence boiling point readings. A slightly lower or higher value can flag leftover reactants or even contamination in storage jars. Chemists look for those telltale shifts. This practice earns extra attention because 2-Bromotoluene, if released or disposed of wrong, sticks around. It’s not just the smell or residue left behind; the compound’s persistence in the soil and water raises environmental problems over time. Researchers tracking contaminants in water samples repeatedly find halogenated aromatics traced back to manufacturing or improper waste management.

Moving Toward Safer Practices

Clear labeling, glove use, face shields, and fresh air all matter more with compounds carrying high boiling points and potent vapors. Anyone working with 2-Bromotoluene or similar choices heads back to basics: temperature logs, double-checking storage protocols, and limiting unnecessary exposure. Teams often install updated scrubber systems to grab stray vapors before they turn into bigger problems. One example stands out where my group changed over to digital alerts on heating baths—cutting away the overlooked risk of unattended flasks losing control.

Looking Ahead

Researchers keep looking for alternatives that keep the chemical benefits of compounds like 2-Bromotoluene but lower the hazardous profile. Adjusting synthetic targets, using closed systems, or even turning to green chemistry routes form part of this push. Workers and scientists who rely on facts like a boiling point aren’t just reciting trivia—they’re drawing the battle lines in handling chemistry safely and responsibly.

Why Proper Storage Matters

2-Bromotoluene isn’t just a common chemical in labs and industries. It acts as a starting material in everything from pharmaceuticals to dyes. Keeping this compound safe and stable means thinking beyond a locked cabinet or a dark corner. A chemical spill or fire can put real people in danger, cause company losses, and even harm the environment. Choosing the right approach cuts down on risks and shows a commitment to safeguarding both health and equipment.

Main Risks with 2-Bromotoluene

Anyone who’s spent time in a lab understands that organic chemicals deserve respect. 2-Bromotoluene comes with its own hazards—it releases toxic fumes if burned and can irritate skin, eyes, and airways. Poorly stored, this clear, oily liquid might leak, evaporate, or react with incompatible materials. Mishandling can bring down a lab’s safety credibility and might trigger emergencies that nobody wants to face.

Conditions for Safe Storage

A smart strategy starts with a cool, dry, and well-ventilated area. Exposure to heat, sunlight, or open flames can turn it dangerous in a hurry. Don’t shove it near strong oxidizers or acids—these pairings have a reputation for explosions or violent reactions. Taking the time to check the safety data sheet isn’t just a formality; it’s practical science in action. Double-check labels, keep containers tightly sealed, and make sure they’re made from materials that don’t react with aromatics.

Several respected sources—including the National Institute for Occupational Safety and Health (NIOSH)—stress temperature control. A consistent room temperature helps limit evaporation and pressure build-up inside bottles. That bit of extra caution pays off down the line. I’ve seen cracked lids and swollen containers from simple carelessness, which sent maintenance into high-alert mode and wasted everyone’s time.

Minimizing Everyday Risks

Don’t store 2-Bromotoluene overhead or on a crowded shelf. Shelf spills rarely stay contained, as gravity finds the weakest link fast. Instead, a low shelf inside a secure, dedicated flammables cabinet works far better. Labs with good track records keep incompatible chemicals separated, and where I worked, color-coded bins made this job easy to track. Simple visual cues help both new hires and old hands avoid bad mix-ups.

Every container deserves clear, legible labels showing chemical name, hazard symbols, and the date opened. No room for mystery here. Routines such as checking for leaks or cracked seals each week catch problems before they get bigger. I’ve learned the value of documenting storage and disposal as well—when someone needed a chemical, we always knew where to find it, and when it passed its shelf life.

Training and Emergency Steps

Even a solid storage plan needs regular refreshers. No one benefits from an employee guessing at storage rules. Each person who handles chemicals should get straight talk about where to find spill kits, fire extinguishers, and eye wash stations. Timely drills and quick reference posters reduce panic during a crisis.

Fire safety lands high on any list involving flammable chemicals. 2-Bromotoluene demands the right extinguisher—dry powder or foam instead of water. As someone who once spotted a water extinguisher parked near the solvent fridge, I can say simple checks avert disasters. Clearly marked emergency exits and an up-to-date contact list round out a good safety culture.

Better Practice: Better Peace of Mind

Companies that stick with strict storage habits enjoy fewer accidents and less downtime. The upfront cost of good cabinets and training runs smaller than cleanup or liability claims. In the end, the safety of staff and the integrity of the lab or plant matter most. Keeping things sensible and standardized builds trust and keeps the science moving without interruption.