2-Bromoaniline: Legacy, Uses, and Future Pathways

Historical Development

2-Bromoaniline entered the global chemical landscape in the late 19th century. Chemists then devoted themselves to finding new ways to tweak simple aromatic compounds, chasing after pharmaceuticals, dyes, and new materials. Discovering the bromination of aniline gave all sorts of tinkerers the ability to make intermediates needed for more complex synthesis. Over time, as industry scaled and methods matured, researchers refined the isolation and purification of this compound, turning rough chemical processes in small glassware into robust manufacturing lines. From old-school bench-top glassware to today’s computer-controlled reactors, the path of 2-Bromoaniline traces a timeline of both innovation and scale.

Product Overview

2-Bromoaniline stands out as a versatile intermediate. Typically presented as an off-white to pale yellow crystalline solid, this compound carries a faint amine odor that signals its aromatic amine roots. Its molecular formula C6H6BrN gives it just enough complexity for precision work, yet stays manageable in both lab and industrial settings. Widely sought by pharmaceutical, agrochemical, and dye manufacturers, chemists rely on it as a building block for synthesizing more elaborate structures. The ability to substitute groups on the aromatic ring makes this compound a staple in both small-batch research and industrial synthesis.

Physical & Chemical Properties

Physical properties of 2-Bromoaniline matter greatly for safe handling and process optimization. It melts at around 26–28°C, trickier than many organics since it can shift easily from solid to liquid in a warm room. Boiling kicks in at about 251°C, a number that underlines the need for careful apparatus and fume management. Solubility runs low in water but jumps in organic solvents, echoing its hydrophobic backbone. Chemists know the bromine atom on the ring activates the molecule for further halogenation or for reactions like nucleophilic substitution, but the adjacent amino group tempers that reactivity, sometimes demanding a steady hand during transformations.

Technical Specifications & Labeling

In the plant or the storeroom, 2-Bromoaniline must come marked with precise specifications. Purity often runs higher than 98% for research and pharma contexts, and certificate of analysis covers moisture, residual solvents, and heavy metal content. Labels carry warnings required by legislation like CLP in the EU or OSHA in the US, reflecting irritant hazards and the need for gloves, goggles, and ventilation. Packaging usually favors opaque glass bottles or fluorinated plastic, sealing out moisture and preventing degradation. Barcodes link back to batch records for traceability, ensuring a recall or investigation hits the right batch if a problem appears.

Preparation Method

Most 2-Bromoaniline made today comes from brominating aniline using molecular bromine in glacial acetic acid. The electronics of the aromatic ring direct the bromine to the ortho position, right beside the amino group. Careful control of temperature and stoichiometry stops over-bromination and keeps the product profile tight. Some chemists prefer N-bromosuccinimide (NBS) for a cleaner alternative, especially at small scale. After reaction, isolation usually involves neutralization, aqueous washes to remove acids, and distillation or crystallization for purity. At the industrial level, closed systems and scrubbers take care of fumes and liquid residues, pushing both yield and environmental compliance.

Chemical Reactions & Modifications

2-Bromoaniline acts like a versatile toolkit for chemists. The bromine atom lends itself to cross-coupling reactions—think Suzuki, Heck, or Buchwald-Hartwig—opening doors to new carbon–carbon or carbon–nitrogen bonds. The amine side enables diazotization, followed by Sandmeyer or coupling steps to build complex aromatic systems for dyes or active drugs. Some use it to build heterocycles, tapping into both the amine and the aryl halide moieties in tandem. Reduction, acylation, and alkylation further broaden its applications, allowing rapid prototyping of candidate molecules in medicinal chemistry.

Synonyms & Product Names

Chemists might know 2-Bromoaniline under names like o-Bromoaniline, 1-Amino-2-bromobenzene, or Benzenamine, 2-bromo-. Older literature includes ortho-Bromoaniline or 2-Bromophenylamine. This multiplicity can bring confusion, yet regulatory and safety databases list all major aliases, reducing mislabeling or shipment mistakes. Vendors often stick with the IUPAC name to keep legal compliance front-and-center.

Safety & Operational Standards

Working with 2-Bromoaniline calls for real care. Breathing in vapors, skin contact, or accidental ingestion can put health at risk. Documented effects range from eye, skin, and respiratory tract irritation to more serious consequences after long or repeated exposure. Researchers must use chemical fume hoods, nitrile gloves, and proper eye protection, and keep emergency showers and eyewash stations close by. Storage works best in a cool, dry, and well-ventilated area, away from acids and oxidizing agents. Standard operating procedures mandate spill kits on hand, clear labeling, and regular training for all handlers. Disposal follows hazardous waste protocols, minimizing soil and water contamination.

Application Area

Demand for 2-Bromoaniline rides on its status as an intermediate. In pharmaceuticals, it acts as a launching pad for antihistamines and cancer drugs, delivering the right molecular backbone for further transformations. Dye manufacturers take it into azo and anthraquinone dyes, pumping out colors for textiles and inks. Agrochemical giants pull it into pesticide and herbicide synthesis, given its ease of tailoring functional groups. Specialty materials like conductive polymers or advanced coatings sometimes rely on derivatives made by functionalizing the original molecule. Research labs treat it as a model compound for teaching aromatic reactivity, too.

Research & Development

Every year, R&D labs build on the foundation set by 2-Bromoaniline. Teams pursue greener bromination methods, swapping toxic reagents for milder, more sustainable processes. Work also focuses on new coupling catalysts, slashing metal loadings and waste. Pharmacologists screen analogues in silico before heading to the bench, hunting for new activities and off-target effects. Computational chemistry reveals new insights into reaction selectivity and environmental persistence. The recent push in machine learning accelerates predictions around reactivity and safety, aiming to keep the pace of discovery brisk while cutting costs and hazards.

Toxicity Research

Toxicity studies on 2-Bromoaniline reveal a profile that demands respect but rarely triggers alarm at low exposures. Animal models suggest acute toxicity, with effects like methemoglobinemia showing up at higher doses. Chronic exposure can sensitize workers and cause organ effects over time. Mutagenicity tests appear inconclusive at small doses, yet researchers flag the need for ongoing vigilance, especially as downstream products enter soil, water, or the food chain. Regulatory limits exist for workplace air, and procedures minimize runoff or accidental releases into the environment. Animal welfare and ethical lab standards continue to shape both the need for, and the design of, future toxicity trials.

Future Prospects

As chemical industries shift toward safer, greener, and more efficient synthesis, 2-Bromoaniline remains a mainstay. Emerging demand for custom pharmaceuticals points toward diversified derivatization and late-stage functionalization on the aromatic ring. Advances in biocatalysis hint at enzymatic routes to halogenated anilines, promising less waste and higher selectivity. Digitalization of chemical process control makes large-scale brominations safer and more cost-effective. Policy shifts mean sustainability and life-cycle analysis will figure more in choice of both feedstocks and disposal. Training the next generation of chemists to weigh urgency and safety goes hand-in-hand with continual improvement in process technology, quality assurance, and environmental care.

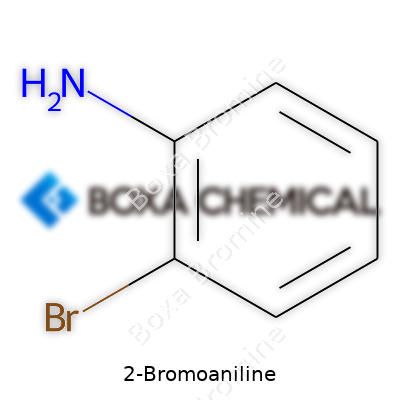

Getting to the Basics: Structure and Identity

Anyone who picks up a bottle labeled “2-Bromoaniline” will see its formula written somewhere near the technical data: C6H6BrN. Here’s how that formula builds up. Start with a benzene ring (C6H6). Swap one hydrogen off the ring for an amino group (NH2), and another for a bromine atom. Stick both of them right next to each other; the “2-” in the name means the bromo group sits right beside the amino group on the ring — chemists call it the “ortho” position.

What stands out with C6H6BrN is how small changes in a molecule shape its character. With 2-Bromoaniline, that bromine throws a wrench in the usual reactivity of plain old aniline. Bromine’s a heavy atom, so it slows the molecule down in some reactions. Its electronegativity and size add new flavors of behavior for anyone looking to build up something bigger from that benzene ring.

Why Formulae Matter: Beyond the Lab Bench

In the pharmaceutical world, the difference between a chlorine and a bromine matters. Production chemists know that when they buy a container marked C6H6BrN, they’re getting material that brings more than just atoms; it brings opportunities and hazards. Having that precise formula lets buyers, sellers, and regulators talk in the same language. They know which gloves to use, which shelf to keep it on, and which protocols stand between a routine day and a dangerous one.

I’ve watched researchers triple-check the structure before scaling up a reaction. The bromine atom doesn’t just influence synthetic strategy; the presence of that nitrogen means basicity and reactivity both jump. That’s why 2-Bromoaniline pops up in dye synthesis, specialty polymers, and even in agrochemical discovery. Without a clear formula, confusion walks in the door — every mistake costs time, money, or health.

Risk, Responsibility and Solutions

Real talk: anyone storing or moving C6H6BrN has to respect the hazards. The presence of both bromine and amino groups means it rarely behaves like other small organics. Failing to recognize that formula could mean unpleasant surprises with human health, from skin sensitization to unknown reactivity. Over the years, I’ve seen newcomers underestimate a simple aromatic amine — and pay in ruined reactions or regulatory fines.

What’s the solution?Transparency and training start with knowledge of formulas. Chemical safety sheets spell everything out, but reading formulas fluently gives an extra layer of protection. Company leaders can push efforts to make structure and risk education more visible. Providing structure apps or visualization tools for new workers makes it harder to breeze past a key hazard.

It’s never just about letters and numbers. C6H6BrN tells a bigger story. That string of atoms changes how labs design syntheses, how factories ship cargo, and how scientists think about risks and rewards. Every bottle of 2-Bromoaniline on a shelf is a reminder: small changes in atomic makeup pack big consequences for workers and the outside world.

Foundations in Chemical Manufacturing

2-Bromoaniline forms the backbone for many chemical syntheses, especially in pharmaceutical and agricultural labs. Whenever research teams search for a way to build more complex, biologically active molecules, they naturally scan benzene rings for places to add new functional groups. Here, the bromo group on the aniline scaffold offers an inviting anchor. In my own college research days, I saw firsthand how adding a bromine atom to aniline could set the stage for big leaps in complexity.

Chemists often use this compound as a starting block for drugs and dyes. Many classic heart medications and antibiotics trace part of their blueprint back to modifications made on the aniline core. With the presence of a bromine atom, chemists run a suite of reactions—Suzuki, Buchwald-Hartwig, and others—to pile on new carbon chains, aryls, or nitrogen compounds. This turns a simple ring into a crowded, busy molecule ready for real biological activity. The bromine not only helps construct the molecular framework, but also guides the next steps, refining which products actually result.

Role in the Dye Industry

Textile labs regularly use 2-Bromoaniline to generate azo and anthraquinone dyes. In the past, I interviewed factory staff at a midwestern pigment plant. Several technicians pointed to this molecule as a reliable workhorse, producing everything from bright yellows to deep reds and blues. This starts with the diazotization of the aniline group and moves toward coupling that intermediate with other aromatic compounds.

Dyes made this way tend to stick well to fabrics, resist fading, and form vivid, consistent colors. Large-scale textile operations value the controllability and reliability provided by such ingredients. While hunger for synthetic dyes has not always been good for the environment, the chemical logic and creative opportunity in these syntheses remain impressive.

Pharmaceutical Pathways and New Medicines

Drug discovery often looks for convenient building blocks. 2-Bromoaniline fits the bill, not just on paper, but in late-night experiments where teams race to assemble new scaffolds. I have seen drug designers deploy this compound to quickly build antihistamines, anticonvulsants, and even experimental cancer drugs. Its versatility opens doors for forming new linkages, especially where other more-reactive atoms might trigger unwanted side reactions.

One hallmark of safe and responsible research involves careful handling. Brominated aromatics like this one should stay in well-ventilated labs, with gloves and goggles on hand. Despite these standard controls, the pace of pharmaceutical innovation often hinges on easy access to just these kinds of molecules. Investigational drugs entering trials often contain a modified aniline backbone—sometimes launched by that one bromine atom negotiable for countless new bonds.

Environmental and Safety Perspectives

Every chemical with a lot of utility comes with some drawbacks. 2-Bromoaniline can irritate skin, eyes, and mucous membranes. Factory workers and lab researchers need training and reliable safety routines. In interviews, environmental specialists warn about spill risks and stress careful waste management, since brominated compounds can linger in water and soil. Advocates push for closed-loop systems and greener chemistry approaches, including catalysts that reduce leftover byproducts.

New solutions appear each year, giving both researchers and industry leaders a way to keep benefiting from this classic intermediate while reducing its environmental cost. Investing in education and updating best practices keeps workplaces safer, and cleaner technology keeps the impact in check.

Understanding the Risks Up Close

2-Bromoaniline plays a role in making dyes, drugs, and sometimes advanced materials. It brings both value and risk into the lab or facility. Recognizing the dangers means comparing it to other aromatic amines, which often carry health warnings. In my early days in a chemistry lab, I remember how the pungent smell and slick liquid texture of these compounds stuck with me. Some of my colleagues developed skin reactions—not just rashes, but sometimes more severe issues that affected their focus and productivity for days.

Direct Contact and Personal Protection

Forget about “just being careful.” Splashing or accidental spills happen in busy work environments. Disposable nitrile gloves act as a basic line of defense. Chemical-resistant aprons and safety goggles keep the splashes away from eyes and clothes. I won’t forget one day a lab mate skipped the lab coat; he wore a favorite shirt and it came into contact with a few drops. After a few hours, his skin showed signs of irritation. That moment reinforced my approach: always suit up, and keep extra gloves within reach. Face shields become handy not just during big reactions, but anytime you pour or transfer the liquid.

Ventilation Beats Guesswork

Most organic compounds bring breathing hazards and 2-Bromoaniline pushes this case even further. Working in a fume hood saves you from inhaling vapors that can cause headaches, sore throats, or worse. In cramped or crowded settings, I’ve noticed stuffy air sometimes persuaded people to cut corners, leaving the sash open too far or stepping out from the hood. My advice remains simple: if a chemical has a smell, it has airborne risks. Don’t risk a headache or increased exposure—ventilation never feels like overkill for these kinds of chemicals.

Handling Spills and Proper Disposal

Spills don’t wait for you to be ready. Kits stocked with absorbents, dedicated chemical waste bins, and a quick cleanup routine help limit harm. Soaking up a small spill with paper towels just spreads contamination. Absorbents and sealable bags offer a real solution. 2-Bromoaniline should never pour down the sink; hazardous waste teams properly handle these. From my days teaching undergrads, I learned that clear labeling on waste containers cut back on panic and confusion, especially during those moments when people didn't want to admit to a mistake.

Training and Information Sharing

OSHA rules require safety data sheets, but no rule works better than talking through real incidents with coworkers. Safety briefings at the start of each quarter help, but hands-on drills or role-playing spills make lessons stick. I saw real improvement when a team handled a mock-splash clean up, compared to how they acted during emergencies in the past. Sharing experiences—why someone got a mild burn, or how a strange smell lingered—means fewer mistakes and a safer environment.

Looking Beyond Personal Safety

2-Bromoaniline’s risks extend to the community and environment. Wastewater or improper disposal can spread chemicals beyond the lab. Building relationships with environmental health specialists ensures safe treatment and responsible disposal. Some institutions invest in chemical recycling systems or safer substitute chemicals—steps that might stretch budgets, but protect both workers and neighborhoods. Championing these investments builds trust both at work and in the wider community.

Solutions Make Safety Real

Simple reminders, easy access to protective gear, regular review of safety steps, and honest talk about close calls anchor a real safety culture. Personal accountability counts. Years in laboratories taught me that shortcuts invite trouble, but small, steady habits protect lives and careers every day.

Digging Into the Numbers

2-Bromoaniline, with the chemical formula C6H6BrN, comes with a molecular weight of about 172.02 grams per mole. This single number—172.02—is not just an academic trivia. For someone in the lab, this value is essential. Getting this right lets chemists figure out exactly how much of a substance to measure out for a reaction, or calculate yields after a day’s work.

Scaled Beyond the Beaker

Calculating molecular weight means adding up the atomic weights of each element: six carbons, six hydrogens, one bromine, one nitrogen. Carbon gives 12.01 each, hydrogen adds 1.01, bromine is the heavyweight at 79.90, and nitrogen drops in at 14.01. The total comes together at 172.02.

Someone might wonder why such a figure matters outside research. In industrial chemical production, the cost, safety precautions, and final product quality all hang on knowing the correct quantities. Transporters, buyers, and quality control labs use the same number to document batches, analyze products, and meet safety obligations. Regulators require accurate reporting, especially with compounds that can influence health and safety, like 2-Bromoaniline.

Health, Environment, and Doing the Job Right

Working with chemicals like 2-Bromoaniline is not something you approach carelessly. Exposure can affect the body, so knowing molecular weight helps calculate exposure doses and design proper ventilation or protective gear. In my early research days, we looked up molecular weights constantly—not just for routine prep, but also to double-check exposure risk or waste disposal needs. An incorrect number in a material safety data sheet could mean real danger for someone down the line.

The right molecular weight also simplifies environmental impact calculations. Let’s say a spill happens. Clean-up crews look up molecular weights to estimate the mass involved and compare it with legal thresholds. This keeps consequences in check and guides quick action. It’s not glamorous work, but safety depends on these details.

Supporting Quality and Trade

In the marketplace, nuances matter. Pharmaceutical companies or specialty chemical vendors need to certify the exact identity and purity of 2-Bromoaniline in every shipment. Analytical chemists run tests, using molecular weight to confirm they’ve got the right compound—this guards against batches getting mixed up. It can also help root out fraud, which does happen with high-value or restricted chemicals. Accurate weights help buyers and sellers see eye-to-eye without distrust or guesswork.

Getting molecular weights right also smooths international trade, where tariffs, import restrictions, and shipping documentation demand specifics. A single error on a document can delay shipments, cause financial loss, or draw regulatory questions. Reliable chemical data brings confidence up and risk down.

Building Solutions for the Future

Everything from digital lab software to regulatory databases could make use of improved, standardized molecular weight data. Making this data more accessible—curated, up-to-date, peer-reviewed—would help the next generation of scientists. Sharing data clearly and connecting it with real-world health, safety, and trade concerns makes these details more than just numbers in a textbook or scientific paper.

Handling Chemicals at the Ground Level

Chemical storage rarely gets anyone excited, until things go sideways. 2-Bromoaniline serves as a tool in research and manufacturing, but safety around this material matters just as much as its performance in a reaction flask. Failing to plan for proper storage risks more than just losing good product—there’s real danger to health and equipment.

Why 2-Bromoaniline Calls for Extra Care

A common sight in labs and specialist industrial settings, 2-Bromoaniline brings hazards that can’t be ignored. This aromatic compound releases toxic fumes if heated or exposed to fire, and it can irritate skin and lungs. In my own lab work, I learned quick that underestimating an aryl halide leads to emergency phone calls and wasted afternoons airing out fume hoods. Taking time to store it right saves everyone a headache.

Choosing the Right Storage Space

Direct sunlight turns 2-Bromoaniline unstable, so I keep it away from windows. Sun exposure speeds up decomposition, sometimes building up pressure inside the container. For safety, a cool and well-ventilated space makes sense. I’ve seen colleagues cram bottles onto overcrowded shelves, but crowding just ups the odds of spills and accidents. Spacing out containers gives you room to work and clears an escape route if something goes wrong.

Container Selection and Labeling

Not all bottles are created equal. Amber glass stands up well to most organic solvents and blocks sunlight, offering some extra protection. I always make sure that caps fit snugly and labels stay legible. Faded writing lands you in guesswork territory—a mistake that can prompt cross-contamination or misuse. Doubt creeps in during audits and clean-outs if labeling goes slack, so a little vigilance here saves big later.

Avoiding Incompatibilities

2-Bromoaniline doesn’t play well with acids, oxidizers, or bases. In one instance, we almost combined it with an acid in a shared cabinet. That kind of interaction spells trouble—fires or explosive reactions aren’t far-fetched nightmares but actual risks. I always double-check chemical compatibility charts and stack incompatible materials on opposite sides of the storeroom, giving each its own zone. Color-coded storage bins work wonders for quick visual checks too.

Limiting Quantity and Exposure

Keeping only the amount needed for short-term work cuts down on storage risks. Some laboratories bring in shopping-cart quantities, but that only increases the scale of any incident. My team keeps backup supply in sealed secondary containers, tucked into lockable cabinets. That way, spills don’t run wild and the room stays clear for urgent access.

Ventilation Matters More Than You Think

One summer, our storage room’s fan quit. Right away, the space started picking up a chemical sharpness that made eyes water and tempers flare. A working exhaust system turns out to be more than a legal requirement—it’s a comfort and a lifeline. I keep vents unblocked and check fan status on a weekly rotation.

Training and Emergency Prep

Nothing beats hands-on walkthroughs for new team members. We run drills on spill cleanup, know where the eye wash sits, and practice evacuations. Emergency plans shape reactions under stress. Quick, clear steps mean less panic. Confident handling during practice builds muscle memory, which proves invaluable if things ever go wrong.

Building a Culture Around Chemical Safety

Treating hazardous chemicals as basic tools backfires. Each bottle deserves inspection, labeling, and careful placement. By focusing on organization, environment, and communication, I create a safer and more reliable workspace, both for today and the long run.