2,4,6-Tribromophenol: Insights into a Versatile Compound

Historical Development

Long before flame retardants became a common part of industrial safety, chemists explored halogenated phenols as powerful preservatives and intermediates. 2,4,6-Tribromophenol came out of this period, where early organic chemists in the late 19th and early 20th centuries experimented with bromine substitution in aromatic compounds. Early records suggest that researchers synthesized tribrominated phenols in the quest for more effective antiseptics and wood preservatives. As large-scale chemical manufacturing took off in the mid-1900s, this compound, with its notable stability and performance, found use in fields far beyond the original laboratory.

Product Overview

This compound has stood out for its versatility. Used across flame-retardant applications, epoxy resin manufacturing, and as an intermediate in synthesizing pharmaceuticals and fungicides, 2,4,6-Tribromophenol goes well beyond a single niche. Its popularity in both bulk and specialty markets speaks to the value people find in one compound that answers so many requirements, especially in settings where safety, reliability, and performance can’t fall short.

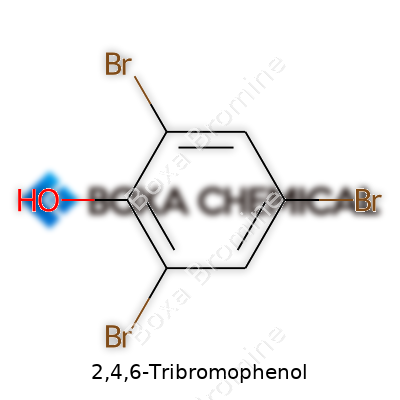

Physical & Chemical Properties

Holding the chemical formula C6H3Br3O, 2,4,6-Tribromophenol appears as white to light-pink crystals and brings a faint, phenol-like odor. Its molecular weight of 330.8 g/mol reflects the presence of three heavy bromine atoms, which also push its melting point up to around 95-98°C. The compound dissolves more readily in alcohol, ether, and other organic solvents, and resists solubility in water due to its dense halogenation. For storage and handling, solid form keeps best in cool, dry conditions to preserve its quality.

Technical Specifications & Labeling

Manufacturers set tight tolerances on purity and bromine content, as even minor impurities can disrupt downstream uses. Specifications typically require at least 99% purity and a melting range within a couple degrees to help buyers assess quality. Product labels need to display the CAS number (118-79-6), molecular formula, batch number, and storage guidelines, aligning with international chemical transparency standards. These details matter not only for compliance but also for worker safety and rigorous process control.

Preparation Method

Industrial synthesis often relies on direct bromination of phenol using bromine in water or glacial acetic acid as solvent. Controlling temperature and reaction rate is critical; too much agitation or heat causes unwanted byproducts or over-bromination. Some producers fine-tune reaction conditions with catalysts or buffering agents to push selectivity, depending on what impurities they need to avoid. After reaction, the product crystallizes out of solution and then undergoes filtration, washing, and drying to meet technical and safety requirements.

Chemical Reactions & Modifications

2,4,6-Tribromophenol lends itself to a range of modifications. Its phenolic hydroxyl group undergoes etherification, esterification, and coupling reactions easily, giving manufacturers a platform for advanced flame retardants or functional polymers. Bromo groups at the ortho and para positions confer electrophilicity, enabling nucleophilic displacement in further synthesis—valuable in the development of pharmaceuticals, pesticides, and specialty coatings. In large-scale chemistry, these predictable transformations enable creators to build products with precise fire resistance and structural properties.

Synonyms & Product Names

In global commerce, this compound appears under names like TBP, phenol, tribromo-, or simply Tribromophenol. Some sectors refer to it by trade names or as a key additive for building flame-retardant resins. The proliferation of synonyms reflects broad adoption across regions and industries, so technical and procurement teams often watch for label details to avoid mix-ups with close relatives like pentabromophenol or other halophenols.

Safety & Operational Standards

Worker protection and environmental control are top priorities. Direct contact with 2,4,6-Tribromophenol can irritate the skin, eyes, and respiratory tract, underscoring the importance of gloves, goggles, and fume extraction in production halls or labs. Regulatory agencies require detailed safety data sheets spelling out hazards, first-aid, and spill procedures. Facilities handling the compound routinely audit storage systems, waste streams, and emissions, knowing that even a small breach can pose risks downstream. Adhering to frameworks from OSHA, REACH, and similar bodies prevents legal blowback and helps preserve community trust.

Application Area

Building fire-resistant plastics and coatings could hardly proceed without a robust arsenal of brominated flame retardants, and 2,4,6-Tribromophenol plays a defining role here. Epoxy resin manufacturers rely on this compound’s chemistry to gear up products that satisfy aviation, electronics, and automotive industries’ fire codes. Wood preservation, antimicrobial plastics, and even pharmaceutical intermediates depend on the blend of reactivity and stability that comes from its three bromines. Anyone working in electrical or construction markets likely benefits from safer products thanks to these features, even if the underlying science remains invisible to end users.

Research & Development

The march toward more sustainable and less toxic flame-retardant solutions keeps chemists and engineers pushing boundaries. Current R&D efforts look for ways to boost performance while reducing environmental drawbacks: lowering leaching from finished articles, improving biodegradability, or even designing alternative synthesis routes that cut down on hazardous waste. Scientists in academic and industrial labs experiment with analogs and co-additives to create the next generation of fire-safety materials, supported by computational chemistry and rigorous lifecycle assessments. As societies raise standards for product safety, the demand for innovation in this chemical’s applications only intensifies.

Toxicity Research

Concerns about the persistence and bioaccumulative potential of brominated organics call for ongoing study. Animal tests and cell-based research have pointed to possible neurodevelopmental or endocrine effects with large-scale exposures, prompting restrictions and monitoring in some jurisdictions. I’ve seen how regulators balance the trade-offs—how flame safety saves lives, but unchecked release into waterways or soil can create new public health concerns. Robust monitoring programs, transparent reporting, and responsible waste management go hand in hand with continued exploration of safer alternatives.

Future Prospects

What comes next for 2,4,6-Tribromophenol will depend on the intersection of safety, market economics, and evolving regulations. Demand for fire-resistant materials in growing sectors—namely renewable energy, electric transport, and next-generation electronics—keeps the need for reliable flame retardants high. Public pressure and legislation have started to push the industry toward greener chemistry, so those developing and applying this compound must adapt. Whether that means tweaking its use, engineering safer derivatives, or investing in responsible product stewardship, change feels inevitable. Those who manage to balance performance with ecological responsibility will hold a clear edge as the world’s expectations rise.

Why 2,4,6-Tribromophenol Catches Attention

To most folks outside a lab or chemical plant, 2,4,6-Tribromophenol sounds like another tongue-twister straight from a chemistry textbook. For those in the industry, this compound stays on the radar because many daily-use products get their staying power from it. The world depends on chemicals we barely notice, and this one finds itself right in the mix, especially when it comes to safety and hygiene.

Keeping Flames at Bay

2,4,6-Tribromophenol sees a lot of action in flame retardant manufacturing. Brominated compounds slow down how fast materials catch fire and burn. Furniture, circuit boards, wires, building materials—all these things can build up a fire risk, especially in spots packed with people. Adding flame retardants gives people a better shot at escaping if something sparks. Years ago, I worked at a local recycling center. Seeing what ends up in the waste stream opened my eyes to the number of household goods built with these fire-fighting chemicals. Without them, fires would take down buildings a lot faster, and tragedy would strike more often.

Preserving Everyday Products

Another major use for 2,4,6-Tribromophenol involves its power as a pesticide and preservative. Mold doesn’t care about production costs or timeframes—it eats away at wood, textiles, and paper as soon as dampness creeps in. Shipping wood pallets and textiles overseas means risking whole containers turning moldy before they ever hit the shelf. This compound blocks that damage, keeping products fresher and safer. From my work packing up cargo in port warehouses, I watched what happened when a shipment came in contaminated. The financial loss hurt, but exposure to mold caused more subtle and lasting health headaches for the staff too.

Specialty Electronics and Paper Production

2,4,6-Tribromophenol doesn't stop at furniture and textiles. It’s a key player in making fire-resistant resins used in electronics. Printed circuit boards (PCBs) need that added layer of protection. These boards sit inside laptops, phones, and medical gear, putting them under constant heat and electrical stress. A breakdown leads to device failure or, worse, fires directly in someone’s home or hospital.

In the paper industry, this compound keeps manufacturing lines running smoothly. Moist environments inside paper mills spawn all sorts of fungus and bacteria. 2,4,6-Tribromophenol helps keep paper free from discoloration and rot during processing and storage. The result is fewer recalls on finished goods, less waste, and a cleaner, more reliable product.

Concerns and Safer Choices Ahead

Despite its utility, there’s a cost. Brominated phenols can travel through the environment and sometimes stick around in water, soil, and living creatures. Studies link heavy or repeated exposure to harmful effects, especially for folks who handle these chemicals every day. Watching the recycling industry struggle to separate hazardous residues from safe recyclables, I realized just how tough it can be to clean up after persistent chemicals.

Communities and regulators keep pushing for safer alternatives. Green chemistry teams keep looking for replacements that skip the pollution and health risks. Some companies swap in flame retardants that break down more easily after use. Others refine manufacturing to keep chemical releases at rock-bottom levels. Reducing reliance on a single solution calls for teamwork from chemists, engineers, and even end-users who demand safer products.

Staying Aware and Involved

Chemicals like 2,4,6-Tribromophenol remind us that progress rarely happens without trade-offs. It’s easy to see how chemical choices ripple out to affect workers, consumers, and neighborhoods across the globe. Consistent oversight, public pressure, and technical innovation push the conversation forward, hopefully leading to safer products and workplaces in the years ahead.

Why Knowing the Formula Matters

Plenty of folks gloss over the importance of chemical formulas, but that simple string of letters and numbers tells a huge story. 2,4,6-Tribromophenol offers a great example. Its chemical formula is C6H3Br3O. This formula stands for a benzene ring—think six carbon atoms in a hexagon—with three bromine atoms and a single hydroxyl group (the O and connected hydrogen), replacing other hydrogens at certain positions. Reading the formula doesn’t just tell what’s in the substance. You can look at C6H3Br3O and think about how each atom changes the physical and chemical nature of the compound.

Bromine’s Large Impact

Those three bromine atoms carry serious weight, both literally and figuratively. I learned in my university days how easily bromine swaps in on an aromatic ring, especially when a catalyst is around or the chemistry is tuned right. Placing bromine groups at the 2, 4, and 6 positions changes not only the size but also how the molecule reacts. Phenols are already pretty reactive because of the O-H group. Bromination at these three spots makes this molecule easier to use as a fire retardant—brominated organic compounds slow the spread of flames by messing with the combustion process.

Fire safety touches all sorts of stuff around the house—electronics, building materials, furniture. You might notice a chemical smell coming from new electronics, or a slightly odd scent after plugging in a power strip for the first time. Many flame-retardant materials owe their protection to compounds like 2,4,6-Tribromophenol.

Health and Environment: Not Just Academic Concerns

During a stint at a chemical plant, I started wondering if fire retardants might cause side effects. Large-scale manufacture and use means this phenol derivative shows up in water, soil, and, sometimes, food products. Based on environmental research from agencies like the EPA, substances containing multiple bromines can stick around in the environment, traveling up the food chain and building up in animal tissues. Once brominated compounds get into rivers or aquifers, cleaning them out gets expensive and challenging.

Medical journals point out links between high brominated compound exposure and health concerns—thyroid problems, developmental delays, even some types of cancer. Not every study says the same thing, and it’s easy to overreact, but seeing the research firsthand changed how I think about chemical handling and disposal.

Rethinking Chemical Use

Lots of companies have started swapping out brominated flame retardants for alternatives, including phosphorus or nitrogen-based options. Finding greener syntheses hasn’t been simple or cheap. Some groups have switched to materials that simply don’t need as much fire resistance, or that use new polymers carrying fire-resistant properties without bromine or even phenol groups altogether. A few friends from college work in material science, and I hear them talk about bio-based resins showing promising results, slashing toxic release during fires and cutting down environmental impact.

The Takeaway for Researchers and Users

Looking at C6H3Br3O isn’t just for chemists. It points to a whole web of production, regulation, safety, waste, and even ethics. Responsible research and industry practices can help keep public health front and center, pushing for more transparency and accountability. Whether someone’s in a lab, on a factory floor, or shopping for a new laptop, small details in a formula spell out big realities beyond the classroom or the label.

Peeling Back the Label

2,4,6-Tribromophenol pops up mainly in chemical plants and industrial settings. It shows up in flame retardants, wood preservatives, and sometimes in dyes for textiles. Over the years, companies found it useful for stopping fires and bug attacks on furniture. So, the stuff isn't new in manufacturing circles. If you work in one of those industries, you've probably seen drums labeled with chemical warnings. Trouble is, many people in smaller workshops, or even school science labs, rarely read much beyond the hazard diamond.

What Science Says About Safety

Diving into the research, scientists flagged 2,4,6-Tribromophenol for a reason. People exposed to it in high concentrations sometimes complained about burning eyes, skin irritation, and breathing issues. The chemical could burn skin if you handle it wrong, which really stings. Tests in labs found this molecule can also harm cells in fish and plants, so spills in rivers or lakes mean real-world danger for wildlife.

Long-term health effects can get more serious. Reports show 2,4,6-Tribromophenol sometimes messes with the thyroid gland if the levels build up in the bloodstream. The thyroid acts as the body's thermostat. Mess with it, and everything from energy to mood can go off track. Lab animals exposed over time sometimes showed damaged livers and changes in hormone levels too.

Beyond the Lab—What Happens in Real Life?

In a furniture shop or electronics plant, workers come close to 2,4,6-Tribromophenol on a regular basis. Without gloves, goggles, or good ventilation, small exposures pile up. In my own years working around industrial sites, I noticed lots of people skip safety steps, especially at the end of a long shift. More than once, folks came in with rashes and coughs but just shrugged it off. Long exposures add up, and trouble shows up months later.

Even outside the factory, 2,4,6-Tribromophenol leaks into the environment. Waterways near chemical plants sometimes test positive for brominated compounds, even far downstream. People who drink from contaminated sources, or eat fish caught there, end up in the path of low-level exposure. It doesn’t take a stretch to see how these molecules get back into town water supplies.

What Can We Do?

It takes real effort to dodge these problems. Factories need tough rules about wearing protective gear and handling chemicals. Plant managers should make spill clean-up and air extraction a daily routine, not a back-burner thing. Government inspectors checking up on smaller plants do the community a service—surprise visits often keep people honest about what goes out the back door and into the river.

Outside industry, everyday folks can ask where their furniture and plywood comes from. Support local timber businesses that avoid toxic preservers. Push for tougher water testing in towns close to chemical sites. It helps to share info too; I keep a list of which brands use fewer flame-retardant chemicals and hand it to friends stocking up on kids’ furniture. Small actions spark bigger change, and keeping chemicals like 2,4,6-Tribromophenol in check makes everyday life safer for everyone.

Why Proper Storage Deserves Attention

Not every chemical raises alarm bells. 2,4,6-Tribromophenol stands out because mistakes during storage can create hazards. This stuff doesn’t behave like table sugar. Its toxicity and fire risk need a clear head and careful action. I once worked in a place where someone ignored storage protocols, thinking “these things don’t explode.” That arrogance led to a smoky evacuation one morning. Those memories don’t fade. For a chemical with this track record, a locked cabinet and casual attitude could mean a real mess.

Reliable sources, like the U.S. National Library of Medicine, list 2,4,6-Tribromophenol as hazardous for skin, eyes, and the environment. Simple exposure can irritate the throat and nose. Risk of combustion rises around heat or sparks. The point: shortcuts belong nowhere near this material.

What Works: Practical Storage Solutions

A secure, climate-controlled space creates the best defense. Polyethylene containers, tightly sealed, block leaks and vapors. Strong shelving and good ventilation make all the difference. Dusty, cluttered storage invites accidents. Choose a spot free from sunlight, because UV light can speed up breakdown and create fumes nobody wants to breathe.

Keep 2,4,6-Tribromophenol far from oxidizers and open flames. I’ve seen how well-meaning workers store incompatible chemicals near each other. Mixing strong acids or oxidizers with halogenated phenols deserves a red-flag warning. If in doubt, check the Safety Data Sheet: in one fast scan, it’ll outline incompatibilities.

Label every container with the full chemical name and hazard warnings. Quick, clear signage prevents confusion in emergencies or busy shift changes. If you’re storing larger quantities, don’t overcrowd. Build in easy access and clear emergency routes. I can’t count the number of times training overlooked things like bolt cutters for padlocks—or fresh gloves for spills. Small details often separate a regular day from a story you tell for years.

Real-Life Lessons: Staying Ahead of Trouble

Proper personal protective equipment isn’t just a “best practice” phrase. Gloves made of neoprene or nitrile, snug safety glasses, and simple lab coats make hands, eyes, and skin less likely to meet trouble. Ventilation stands as the unsung hero here. Fans that push fresh air through the storage area keep fumes from building up. If dry powder builds up outside containers, a vacuum with a HEPA filter outperforms brooms—no one wants dust kicked up.

Spill kits backed by regular drills set strong teams apart. In my first month on the job, a seasoned supervisor handed me a bucket and a spill sock, asked me to practice containment, and quizzed me on the next steps. That drill built muscle memory that helped later, under real pressure.

Better Storage, Fewer Headaches

Treating 2,4,6-Tribromophenol with respect goes beyond the letter of regulations. Companies that train staff, invest in better containers, and set up solid ventilation dodge plenty of headaches. Clear procedures for handling, from delivery to disposal, save money and keep staff healthy. Safe disposal partners play a key role because this chemical doesn’t belong down the drain.

Ultimately, storerooms filled with chemicals like 2,4,6-Tribromophenol succeed on practical planning. Shortcuts cost more in the end. I’ve seen what works and what fails, and every time a team focused on training, labeling, and ventilation, accidents faded and work got easier for everyone.

Paying Attention to the Basics

Working with chemicals makes you double-check everything, and 2,4,6-Tribromophenol teaches that lesson every step of the way. This compound, used in flame retardants and some resins, doesn’t belong around bare skin or careless hands. Many folks don’t realize it causes irritation with simple contact. A big part of working safely involves respecting even those substances that rarely make headlines.

Using Personal Protective Equipment

Gloves made of nitrile or neoprene provide a simple line of defense. They beat latex for resisting this compound’s reach. Long-sleeved lab coats and closed shoes keep exposed surfaces to a minimum. Face protection – a solid pair of splash goggles or even a face shield – handles splashes you never see coming. You might think goggles look awkward, but the burning sensation from a chemical splash sticks around much longer. For protracted work, a good respirator rated for organic vapors makes a difference, especially if the room’s airflow proves spotty.

Good Habits in the Workplace

I always lean heavily on proper ventilation. A fume hood stays on my list of essentials, not just for show. Letting vapors drift through a lab can set off headaches, and extended exposure piles up health risks. Eating and drinking anywhere near where you handle, weigh, or transfer this chemical stays off the table. Soap and water become close friends; I wash up twice before touching my phone or face. Accidents can happen, but a culture built around careful work and clear routines narrows the chance.

Storing Chemicals Safely

Dry, cool, and locked down. This isn’t a suggestion; it keeps emergencies from turning into disasters. Chemical compatibility charts have helped me prevent mistakes, like storing different reactive powders together. Clearly labeled containers, well away from acids and strong alkalis, lower the odds of a dangerous mix-up. Waste disposal deserves the same careful attention. The proper drum or hazardous waste bottle keeps used material from finding its way into water or trash streams.

Handling Spills and Accidents

Even the most careful workers run into a spill eventually. For small messes, absorbent pads and neutralizing agents clean up without a scene. Larger spills need a plan – proper evacuation, calling safety staff, and never tackling it solo. Emergency showers and eyewash stations save eyesight and skin, so it pays to know exactly where those are before pulling open any containers. Reporting every incident, instead of brushing it off, lets everyone learn what to watch for next time.

Training and Sharing Knowledge

Staying safe means constant learning. Training updates, clear signage, and frequent walkthroughs keep the right habits fresh in everyone’s mind. I remember a time someone new to the lab hesitated before asking for a glove change. That moment reminded me how powerful open communication can be. Risk shrinks when people share what they know.

Improving the Culture

It doesn’t take expensive gadgets to keep people safe. Consistent routines, reliable protective gear, and accessible training build confidence and focus. Chemicals like 2,4,6-Tribromophenol don’t leave room for shortcuts. Many bad situations start with simple neglect. Talking about risks, showing proper technique, and never treating shortcuts as clever tricks help everyone get home without injury.