Exploring 1-Butanesulfonyl Chloride: Past, Present, and Future

Historical Development

Chemistry has seen certain reagents pop in and out of favor as new methods and needs emerge. Over fifty years ago, researchers started using 1-Butanesulfonyl chloride while working through new avenues for stably activating organic molecules. Aldrich first cataloged it in the 1960s as laboratories began branching out from traditional acid chlorides. In the 1980s, Japanese and German chemists recognized its value for protecting groups and alkylsulfonylation. This chemical’s reliable nature kept it on synthetic benches across both academic and industrial labs. It filled a practical role for anyone who needed a reactive, safe, medium-chain sulfonyl chloride—often called "n-butanesulfonyl chloride" in older texts. Its adoption followed the rise of easier access to alkylsulfonyl reagents and remains tied to the progress of synthetic organic chemistry.

Product Overview

1-Butanesulfonyl chloride serves a vital part in modern laboratories. Coming out as a clear to light yellow liquid with a strong, stinging smell, you quickly learn to respect its fumes. Chemists working with it value its balance between reactivity and safety compared to shorter-chain analogs like methanesulfonyl chloride. Well-sealed amber bottles keep it safe from moisture and light. Manufacturers produce it to industry standards, often supplying it to pharma companies, fine chemical makers, and academic labs who need a reliable source for advanced synthesis.

Physical & Chemical Properties

Anyone opening a bottle of 1-butanesulfonyl chloride immediately notes the acrid odor. It boils around 124 °C and holds a density near 1.2 g/cm³ at 25°C, which puts it a bit heavier than water. In my time as a bench chemist, handling it repeatedly meant extra care with gloves and goggles. It dissolves well in most organic solvents but breaks down in water, releasing corrosive gases. The sulfonyl chloride group at one end does most of the heavy lifting, letting chemists swap it out for various functional groups. Its moderate volatility means it sticks around if spilled, making fume hood work non-negotiable.

Technical Specifications & Labeling

A bottle of 1-Butanesulfonyl chloride always carries a handful of specific warnings. Labeling includes a skull-and-crossbones pictogram for toxic inhalation, along with corrosive warnings. Typical purity for research applications lands between 98-99%. Risk phrases remind workers about burns, lung irritation, and the need to avoid contact with skin or eyes. Labels call out the UN number (UN 3265) and stress that proper secondary containment and storage are required. Some suppliers add UV-blocking agents to slow decomposition. Each bottle often shows batch-specific details: origin, purity by gas chromatography, trace metal analysis, and specific gravity—a testament to the field’s attention to operational risk.

Preparation Method

Production methods for 1-butanesulfonyl chloride started out simple. Most commonly, manufacturers treat n-butane with chlorosulfonic acid; this direct sulfonation produces the sulfonyl chloride function on the four-carbon chain. Alternative methods use sulfur dioxide and chlorine gas in the presence of an initiator but tend to be more expensive and less selective. Scaling up requires process chemists to fine-tune temperature and reaction time to avoid by-products or tar formation. Each step produces hazardous fumes and requires robust ventilation, tight process controls, and experienced operators. The freshly crude 1-butanesulfonyl chloride must undergo vacuum distillation, separating out lower chain (C1–C3) sulfonyl chlorides and any sulfuric acid contaminants.

Chemical Reactions & Modifications

Few other sulfonyl chlorides offer the mix of reactivity and practical handle found in this molecule. One experiment comes to mind from a medicinal chemistry project, where it transformed primary amines into n-butanesulfonamides with high yields and clean profiles. Reacting with alcohols, it produces sulfonate esters, which make excellent leaving groups for nucleophilic substitution. Its mild steric bulk can influence selectivity when building up heterocycles or blocking competing sites. Reductive work can dial the sulfonyl group down to a butylthioether, unlocking further transformations. The butanesulfonyl moiety often ends up as a temporary "mask" or protecting group in complicated multistep syntheses. Compared to its lighter cousin, methanesulfonyl chloride, it offers a bit less volatility and a different polarity—differences that do matter in practical bench work.

Synonyms & Product Names

Shoppers and chemists run across a variety of names: n-Butanesulfonyl chloride, 1-Butylsulfonyl chloride, and Butane-1-sulfonyl chloride lead the list. In German catalogs it’s “Butansulfonsäurechlorid.” Registry numbers cut through the name game: CAS 17620-02-5 appears on every bottle. Researchers sometimes abbreviate it "nBuSO2Cl" in lab notebooks or publications. The diversity of names across languages and contexts highlights demands for clear, searchable labeling, especially with the growth of global chemical markets.

Safety & Operational Standards

Anyone handling this stuff in the lab wears respect for its hazards on their sleeve. The chemical’s strong fumes attack skin, lungs, and eyes, and once you get a whiff, you never forget. Regular safety meetings in chemical plants always include it among notable "corrosives and toxics.” Spills damage floors and metal surfaces; neutralization takes careful use of sodium bicarbonate or other neutralizing agents, always under fume extraction. Manual transfer gets replaced with closed systems at any decent-sized facility, and rigorous leak detection goes into pipework. The key lesson—use only in certified chemical fume hoods, keep neutralizers nearby, and make sure spill training happens before opening the first bottle. Inhalation or skin exposure can hospitalize, so emergency showers and eyewash stations form non-negotiable infrastructure. Storage calls for tight lids, cool temperatures, and non-reactive shelving—never keep it in glass near strong bases or acids.

Application Area

During my time at a contract R&D lab, I saw 1-butanesulfonyl chloride prove valuable for more than synthetic method development. Medicinal chemists in pharma use its sulfonyl function to introduce new functionalities onto peptide drugs or block reactive amine groups. Materials scientists leverage its role to build up tailor-made sulfonate esters in special plastics or ionic liquids. Agrochemical companies test new butanesulfonamide herbicides and fungicides in dozens of small-scale reactions, applying this chemical as a stepping stone. Academic labs incorporate its derivatives as intermediates in probing biological pathways, particularly where soft blocking groups help fine-tune reactivity.

Research & Development

Ongoing research focuses on unlocking new downstream products. Chemists are tuning reagent conditions to add the n-butanesulfonyl group with higher stereoselectivity, giving medicinal compounds finer-tuned activity profiles. Green chemistry advocates look for solvent alternatives and gas scrubbing solutions that cut down on risks and waste from large-scale use. Biomedical researchers check if sulfonamide products built from 1-butanesulfonyl chloride offer improved pharmacokinetics or reduced toxicity. Some groups build microreactors for continuous flow transformations, minimizing exposure for workers and lowering the chance of environmental release. Each conference cycle brings news on more efficient, greener syntheses using sulfonyl chlorides as versatile starting points.

Toxicity Research

Safety teams and academic labs assess how 1-butanesulfonyl chloride interacts with living cells and the environment. Published studies show it causes severe irritation to the upper airway, and exposure above recommended thresholds leads to significant lung and eye damage. A few animal studies note possible chronic effects from repeated low-level exposure, but the data aren’t always consistent. Its hydrolysis product, butanesulfonic acid, proves less aggressive but demands careful wastewater treatment. No evidence yet ties it to long-term cancer risk, though this hasn’t stopped regulatory bodies from insisting on harm minimization. Emergency protocols for spills call for airtight evacuation, and all containers must have clear poison and corrosive hazard labels. The low flash point adds fire risk to the profile, especially in poorly ventilated storage.

Future Prospects

The demand for sulfonyl reagents continues rising as chemists chase more sophisticated ways to manipulate molecules. Next-generation battery developers eye new ionic liquids using n-butanesulfonyl groups for high-voltage stability, while pharmaceutical innovators test fresh sulfonamide drug candidates for selectivity and metabolism. Tighter workplace rules and the push for green chemistry keep pressure on producers to reduce emissions during manufacture and use. Tech-savvy companies are investing in automated bulk handling, keeping human contact with 1-butanesulfonyl chloride to a minimum. Advances in remote synthesis and continuous flow reactions may help broaden its industrial use while reducing direct worker exposure. If new data can show lower environmental persistence or nontoxic breakdown products, its application space could keep expanding far beyond its original niche in synthesis.

What This Chemical Actually Does

A lot of people outside of chemistry circles haven’t heard of 1-butanesulfonyl chloride. In a lab, folks treat it with a whole lot of respect. This compound steps up whenever a chemist wants to add a sulfonyl group to another molecule. The reason? It reacts quickly with certain building blocks—think amines and alcohols—turning them into new chemicals that folks in pharmaceutical, material science, and dye industries value.

Behind the Scenes: Building Blocks for Big Discoveries

Drug makers don’t operate in isolation. They rely on basic ingredients that let them tweak and fine-tune molecules until they behave a certain way in the body. 1-Butanesulfonyl chloride does a heavy lift in this space. Medicinal chemists lean on it to make sulfonamide groups, which show up again and again in antibiotics, diabetes meds, and even drugs that treat epilepsy. It’s no accident. The addition of the sulfonyl group can help a drug sneak through cell walls or dodge enzymes that break it down too fast.

Human health rides on these tiny tweaks. According to a study from the journal Drug Discovery Today, nearly one in five new small-molecule drugs includes a sulfonamide function. The applications cover a huge range—not just in pills, but also in anti-cancer compounds that researchers believe could be the next big step for targeted therapies.

Role in Material Science and Beyond

It doesn’t end with medicine. Polymer scientists depend on 1-butanesulfonyl chloride to modify plastics and rubbers, making materials tougher or more resistant to heat. Textile research makes use of it while preparing specialty dyes and advanced fabrics. Without compounds like this, a lot of breakthroughs—from moisture-wicking gym clothes to medical implants—just wouldn’t hold up.

I once met a coatings engineer who described using this compound to help paints stick better to metal pipes in chemical plants. They needed a paint that wouldn’t peel when exposed to corrosive gases. The secret? Adding sulfonyl groups bolstered resistance and kept those pipes protected longer.

Weighing the Risks

With all the good it does, handling 1-butanesulfonyl chloride demands a careful approach. This chemical can burn skin and eyes, and it puts off nasty fumes that hurt lungs if you breathe them in. Labs must follow strict safety rules—ventilation, gloves, face shields—to keep people safe. The same goes for wastewater. You can’t just pour it down the drain. Environmental guidelines require neutralizing or collecting sulfonyl chloride waste for proper disposal.

Accidents happen, and ignoring the safety issues would be short-sighted. In 2020, the National Institute for Occupational Safety and Health in the US listed sulfonyl chlorides among substances calling for significant extra precautions in academic and industrial settings. Regular training and solid protective equipment reduce the odds of harm.

Responsible Use and Smarter Practices

Green chemistry keeps moving forward. Several research groups are trying to make reactions with 1-butanesulfonyl chloride more efficient, so less gets wasted. Some folks in academia are teaching chemical reactions with friendlier alternatives, hoping to lower the overall risk. The chemical itself probably isn’t leaving labs soon, but the culture around its use reflects a new respect for both people and the environment.

The story of 1-butanesulfonyl chloride is familiar to anyone who’s spent time in science: small ingredients can unlock huge changes. We owe a lot to the chemists who treat these building blocks with both ambition and care.

What This Chemical Demands

1-Butanesulfonyl chloride isn’t the sort of thing you leave lying around in a drafty storeroom. Having worked in labs where chemicals landed on shelves with only faded labels for identification, I learned that everyday discipline saves a lot of trouble down the road. This compound falls into a family of sulfonyl chlorides known for their reactivity. Spills or leaks can spark harsh fumes—a real concern for anyone nearby.

Temperature and Atmosphere Count

Keep it cool. Temperatures above 25°C encourage decomposition or vapor release. Simple shelving in a room with erratic climate control won’t work. At one job, we stored similar reagents in a climate-stable, chemical-safe refrigerator set to 2–8°C. This scale depends on the size of your operation, but the principle holds whether you’re working in a university closet or a large manufacturing space: minimize heat.

Moisture Is the Enemy

Moisture triggers a reaction that produces corrosive hydrogen chloride gas. I saw the havoc once after humidity crept into a supposedly tight bottle. The stench filled the store room, causing a panic that still gets talked about. Dry air is essential. Desiccators are simple insurance. If you have dedicated dry storage or can seal the bottles with desiccant packs, you’re ahead of the game. Containers should close tightly every time, no exceptions. Even the best screw caps wear out, so regular checks matter.

Security and Segregation

This isn’t a benign household cleaner. Store it away from acids, bases, alcohols, and water sources. I’ve seen reckless stacking next to oxidizers and cleaning supplies create situations that called for an emergency clean-up. Sulfonyl chlorides will react with nucleophiles, which covers a wide range of standard lab stocks. Think twice before letting it share a cabinet with just anything off the delivery cart.

Eye to the Label, Ear to the Law

Labels must stay readable and point to hazard information. If regulatory agencies come by, documentation gets checked. Safety data sheets keep details at your fingertips. It’s smart to keep a running inventory and log temperatures, something missed only until an accident happens.

Ventilation and Emergency Planning

Any area holding this chemical deserves solid ventilation. Fume hoods or local exhaust take care of accidental releases. One incident is enough to drive home the value: a poorly vented closet had us evacuating, but one well-placed extraction fan prevented that scenario the next time. Emergency showers and eyewash stations should sit within a short sprint’s distance. Don’t count on luck—build habits and plans before you ever twist the cap.

Moving Forward

It only takes small steps to make big changes in chemical storage safety. Daily checks, redundant labeling, and a dedicated, climate-controlled, and dry space reduce risks that don’t announce themselves until something goes wrong. 1-Butanesulfonyl chloride deserves this respect, and team members do too.

Why Respect Matters in the Lab

Some chemicals show clear warnings right away, like the sharp scent of strong acids or the sting of ammonia. 1-Butanesulfonyl chloride doesn’t make a scene, but it carries risks that demand attention. I’ve spent years around labs and workshops, long enough to see what happens when shortcuts replace safety. Overlooking risks with chemicals like this one brings skin burns, ruined equipment, and serious health hazards.

Understanding the Danger

The stuff acts as both a corrosive and an irritant. One spill, and you end up with severe skin or eye damage. The vapor stings airways and triggers coughing, so working in tight, stuffy spaces never makes sense. Besides, 1-Butanesulfonyl chloride reacts hard with water and bases. This means just a wet bench, or even a sweaty palm, could set off a reaction that hurts more than your pride.

Gear Up Right Every Time

For anyone planning to handle this chemical, gloves and goggles need to be as automatic as tying your shoes. Nitrile gloves hold up well against sulfonyl chlorides. A face shield and a sturdy lab coat with good sleeves go a long way in blocking splashes. I’ve seen folks think glasses or old latex gloves are fine. Those stories end with panic and a bottle of running water, or a trip to the emergency room. Never worth the risk.

Keep Fumes in Their Place

Good ventilation isn’t optional. Fume hoods exist for moments like this, protecting your lungs and everyone nearby. For smaller setups, people sometimes try to work next to open windows or fans, hoping for the best. I’d rather trust a fan built by engineers thinking about chemical safety than gamble on a breeze. If your facility lacks proper fume extraction, it’s time to talk with supervisors or push for upgrades. One person’s shortcut puts everyone at risk.

Storage and Transfer—No Shortcuts

Sulfonyl chlorides hate moisture and exposure. Old, cracked bottles or loose caps spell trouble. Keep containers tightly sealed, away from anything wet, far from acids or bases. I’ll never forget seeing a shelf accident caused by loose chemicals stored side by side. Broken glass, toxic fumes, hours scrubbing the mess—nobody left that day without a learning experience.

Transferring needs care too. Always use dry gear and measure out what you’ll use, not more. Spills happen most often when someone tries pouring from a heavy bottle without using a pipette or funnel. More often than not, they try to rush, just to finish up and get home. That’s how accidents stack up.

Steps When Things Go Wrong

Once, I watched someone freeze up after a splash, not knowing what to do. If you get any on your skin, flush with water right away. Same for your eyes—straight to the eyewash, nothing else matters. Report all spills, even the ones you clean up yourself. Emergency showers, spill kits, safety checklists save more than paperwork; they keep colleagues out of harm’s way.

Building a Safer Space

Honest training and real drills help more than glossing over risks. Supervisors should lead by example—no off-the-record handling, no skipping inspections. Support staff and students who raise safety concerns. It’s better to sound cautious than to stand silent after an accident.

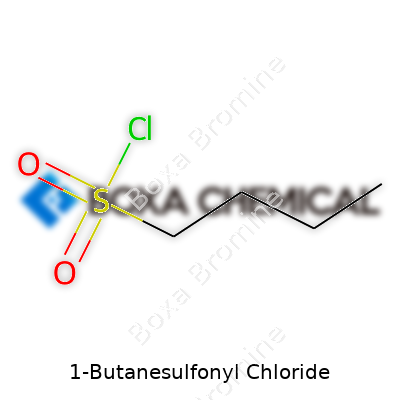

Care and clarity around 1-butanesulfonyl chloride show the difference between real professionalism and luck. Cutting corners puts health, careers, and lives on the line. Simple habits and respect for the dangers make every lab a safer place.Chemical Formula and Molecular Weight

1-Butanesulfonyl chloride packs the formula C4H9SO2Cl. In the world of lab work, seeing this formula tells chemists exactly what building blocks make up the molecule—four carbons, nine hydrogens, a sulfur snuggled up with two oxygens, and a chlorine atom tagging along. If you lay these atoms out, the weight of every molecule comes to 172.63 grams per mole. That number doesn’t just describe a tiny piece of powder; it totals up all those atoms using their atomic masses. For anyone doing reactions or building substances with it, knowing that number helps avoid headache-inducing miscalculations.

Why Formulas and Weights Matter Outside Textbooks

A formula paints more than a textbook picture; it helps chemists know how a substance will react. For years, while helping out in teaching labs and small research groups, accurate weights and formulas separated smooth projects from spectacular failures. A wrong calculation in a sulfonyl chloride reaction can mess up an entire synthesis and eat into grant budgets. When scientists need to make a new drug candidate or specialty polymer, knowing C4H9SO2Cl’s exact makeup means fewer wasted materials and less time fixing errors. I still remember a colleague fouling a batch by using the wrong sulfonyl chloride isomer—easy-to-make paperwork mistakes land as real chemical garbage.

The formula tells more than what fits under a microscope. In practical work, every number on the bottle acts as a silent advisor. Storage requirements and handling rules for chlorine-containing molecules differ from similar-looking compounds. Field experience shows that a little extra care goes a long way when dealing with acid chlorides; proper gloves last longer, and hoods suck up more fumes with these ingredients. The molecular weight also becomes critical in scaling up from a lab bench to a pilot plant. If chemists miss a decimal point, the entire supply chain gets goofy—batches get contaminated, tanks clog up, and downstream users end up with unusable stuff. That’s the kind of trouble bigger plants face if the boring numbers don’t line up.

Supporting Safe and Reliable Use in Industry

Real reliability comes from little pieces of hard information like formulas and molecular weights. Companies making pharmaceuticals, dyes, or agricultural chemicals often use butanesulfonyl chloride as a stepping stone to bigger molecules. Without attention to these basics, dangerous mishaps happen, chemicals escape, and workers get exposed. In some old lab jobs, we had routine drills for acid chloride spills, all because one person forgot to double-check the molecular label. Fact-based handling cuts down on these emergencies.

Room for Improvement

Smarter labeling on bottles and digital logs in labs can cut out formula-related mistakes. Education for new lab workers counts, and so does making safety data accessible. Building small checks into supply chain software keeps firms from shipping off-the-mark material. Even small scale-up projects benefit from digital calculators tied directly to correct formulas and weights. Fellow chemists find life easier with more automation cross-checking formulas in every step. Keeping these facts up-to-date in public databases lets buyers and scientists work with confidence. In an industry with few second chances, precision with details like C4H9SO2Cl’s formula saves money, keeps workers safe, and supports better science.

Understanding the Risk

People working in labs or chemical plants come across a lot of tricky substances. Some make headlines, others quietly do their job, carrying risks that aren’t always obvious to those outside the field. I’ve seen plenty of chemicals get underestimated for years until an accident lands someone in the hospital. 1-Butanesulfonyl chloride is one of those chemicals you won’t find on every shelf, but that doesn’t make it harmless. The stuff can bite if given the chance.

Dangers That Stand Out

If you’ve ever opened a bottle of sulfonyl chloride, the sharp, choking smell tells you it means business. The fumes hit the nose and eyes right away. Just a splash leaves skin red and sore, and anyone breathing it will cough, sputter, and want out fast. The chemical attacks mucous membranes, and that isn’t something to shrug off. Eye exposure can burn, and worst case, rob someone of their vision. Inhalation can scar the lungs, leading to long-term health problems.

Even if you avoid contact or inhalation, 1-Butanesulfonyl chloride reacts with water and moist air, releasing poisonous hydrogen chloride gas. Many people forget, it’s not only the substance in the bottle—they need to worry about what happens when it escapes, even in small spills.

Industry Data and What It Shows

A quick look at its safety data sheets, reviewed by government and independent laboratories, reveals a clear pattern. The document labels it as corrosive, calling for gloves, goggles, fume hoods, and special training. In my time on safety committees, I’ve noticed a direct link between less stringent training and more injuries, especially with chemicals like this one. The American Conference of Governmental Industrial Hygienists (ACGIH) lists substances by health risk. Sulfonyl chlorides, including this one, land squarely in a category that means trouble for exposed workers.

Why It Matters Outside the Lab

While most encounters happen around professional setups, transport accidents, improper disposal, or broken packaging send fumes into neighborhoods, schools, or rivers. If something leaks on a loading dock, the gas released can spread further than many think. Fish and wildlife don’t stand a chance if runoff reaches local streams. In one case I’ve heard, a lab tech misjudged storage, and humidity in the room started a reaction that triggered the building alarm. Emergency teams took hours to clean it up, knowing full well that carelessness can turn a routine job into a health crisis for everyone nearby.

Making Workplaces and Communities Safer

To keep everyone safe, training has to go deeper than a slideshow or a poster by the sink. Workers need real drills and clear, practiced plans for handling spills and accidental releases. Regular checks on containers and air-handling systems catch problems before they worsen. Companies ought to share clear, honest information about the substances they ship and store so emergency crews and neighbors can react if things go wrong. Regulators push for heavier fines in case of mishandling, but from what I’ve seen, a culture of honesty and careful attention does more to prevent harm than just new rules.

In the end, 1-Butanesulfonyl chloride is a powerful tool in the right hands with clear rules and respect for its dangers. Treating it with casual familiarity risks more than just property—it puts real lives, both human and animal, in harm’s way.