1-Bromo-4-Fluorobenzene: A Perspective on Its Development, Properties, and Role in Modern Chemistry

Historical Development

Chemists started paying attention to halogenated benzenes over a century ago. Back in the days of coal tar distillation and sandbox chemistry, simple aromatic compounds gave rise to a wide array of derivatives, each with unique quirks. 1-Bromo-4-fluorobenzene, with both a bromine and fluorine on a benzene ring, didn't emerge overnight. Once researchers understood substitution patterns and could control halogen introduction, production came into reach. Early applications centered around research, particularly as the pharmaceutical industry discovered new scaffolds. Unlike some specialty chemicals, its rise didn't feel like a revolution, but a patient, deliberate progression. Reliable synthetic routes, mainly from p-fluoroaniline or p-bromoaniline, formed as industrial chemistry matured.

Product Overview

People see 1-bromo-4-fluorobenzene as more than an interesting molecule. Chemical suppliers label it as a tool, not just a chemical. It's a clear, colorless to pale yellow liquid, and sits on shelves across research labs as a handled, understood commodity. Its value doesn’t show in eye-catching effects or dramatic reactions. Instead, it serves as a building block for more complex molecules in agrochemicals, pharmaceuticals, and material science.

Physical & Chemical Properties

1-Bromo-4-fluorobenzene has a moderate boiling point, clocking in around 154-155 °C. Its melting point sits lower than room temperature, usually well below 0 °C, leaving it liquid under standard conditions. Its density hovers in the 1.5 g/cm3 range, denser than water but less intimidating than some heavier halogenated benzenes. It brings moderate volatility to the bench. That volatility does more than dictate storage—it matters for safety planning and scale-up decisions. The combination of fluorine and bromine leads to unique reactivity, giving it promise in cross-coupling chemistry. Chemists note its slight, sometimes sweet aromatic odor, a reminder to ventilate workspaces and avoid unnecessary contact.

Technical Specifications & Labeling

Quality assurance isn't just paperwork: every bottle tells a story, from purity to potential impurities. Most commercial offerings note a purity of 98% or higher, sometimes accompanied by data from gas chromatography. Documentation provides details about the water content and residual solvents, since these factors impact downstream applications. Barcodes and batch numbers make tracking easy. Labels also show GHS pictograms and phrases, lining up with international transport and workplace safety standards. Chemical manufacturers take these labeling demands seriously—a missed detail means unnecessary exposure risk for workers and potential trouble in regulatory inspections.

Preparation Method

Synthesis leans on the directed halogenation of benzene rings with established strategies. Most industrial processes start with fluorination of bromobenzene or bromination of fluorobenzene, using selective catalysts or controlled reaction conditions. Electrophilic aromatic substitution dominates, favoring para-substitution for symmetrical substitution patterns. Classic laboratory procedures often use N-bromosuccinimide or elemental bromine, combined with a Lewis acid, for precision. In my early lab experience, poor temperature control produced side reactions, so keeping conditions in check shaped successful outcomes. As green chemistry takes hold, new methods focus on minimizing hazardous waste while protecting product yield.

Chemical Reactions & Modifications

This molecule opens doors in synthetic organic chemistry. It serves as a favored partner in Suzuki and Buchwald-Hartwig cross-coupling reactions, delivering functionalized biaryls and anilines. The C-Br bond reacts readily under palladium catalysis, while the C-F bond usually stays put, waiting for another transformation down the road. Nucleophilic aromatic substitutions run less efficiently on the fluorine, but with the right activators and harsh enough conditions, that bond can switch partners, too. In one graduate project, swapping the bromine for amines or thiols under mild conditions gave easy access to more advanced fragments. Chemists tend to exploit orthogonality between the bromine and fluorine, using one site at a time.

Synonyms & Product Names

Over the years, this chemical gathered a few handles. Some catalogs list it as para-bromofluorobenzene or 4-fluorobromobenzene. Others turn to variants like 1-bromo-4-fluorobenzol, especially in older literature or European sources. In regulatory filings or transport paperwork, the IUPAC name appears most, offering a clear compass through global supply chains. Keeping track of these names prevents ordering mistakes and costly delays. As managers of chemical inventories, recognizing alternate names helps maintain compliance and cuts down on confusion when reviewing paperwork or cross-checking analytical data.

Safety & Operational Standards

Working with halogenated arenes means understanding risks, not just wearing gloves. The bromo group can act as a skin irritant. Volatility brings inhalation risks, and fluorinated compounds raise added concern over bioaccumulation and environmental persistence. Safety data sheets urge ventilation, chemical splash goggles, and gloves made from nitrile or similar resistant materials. Fume hoods play an irreplaceable role in research settings, keeping accidental exposure low even when reactions heat up. Fire risks exist, given flammable vapors at higher temperatures, so spill response plans matter. Chemical hygiene officers stress the need for fresh air, chemical-resistant coats, and strict waste collection procedures. These steps go beyond compliance—they keep people safe day after day.

Application Area

Most of the excitement comes in synthetic chemistry labs. Pharmaceutical companies turn to 1-bromo-4-fluorobenzene as they build up drug candidates with fluorinated components. Agrochemical designers integrate it to adjust bioactivity, tuning molecules for specific herbicides or insecticides. Material scientists work it into monomers for specialty polymers or liquid crystals, chasing properties that only precise halogenation brings. Some emerging battery and electronics applications look to finely tuned benzene derivatives for next-gen performance. My colleagues in academia adore the predictability: this building block lets them test new catalytic systems with reliable results, opening doors to new chemical space once seen as too obscure or challenging.

Research & Development

Research pours into upgrading processes for cleaner, faster, and safer transformations involving 1-bromo-4-fluorobenzene. Scientists seek catalysts that lower temperature and cut down on byproduct formation. More labs invest in flow chemistry, where reactions run in continuous streams, reducing waste and exposure. High-throughput platforms screen newer ligands and metals, pushing efficiency even further. Analytical chemists monitor impurities with modern gas or liquid chromatography, looking for ways to streamline purification. As fluorinated drugs become mainstream, more private firms dedicate research arms to optimizing these fragments for reliable scaling, regulatory approval, and greener chemistry.

Toxicity Research

Reviewing the toxicology, 1-bromo-4-fluorobenzene earns respect, not panic. Animal studies show moderate toxicity, with risks mainly from repeated or high-dose exposure. Absorption through skin or inhalation can produce irritation and, in extreme settings, central nervous system effects. Environmental studies note slow breakdown, with brominated and fluorinated compounds tending to persist. Regulators push for strict handling and waste protocols. Occupational health teams emphasize not just exposure limits but training—knowing symptoms, emergency actions, and proper PPE use. Such perspectives keep the balance, letting researchers benefit from its chemistry without trading away safety or environmental stewardship.

Future Prospects

Looking forward, the story of 1-bromo-4-fluorobenzene will likely parallel the future of fine or specialty chemicals. As drug design leans ever harder on fluorinated scaffolds, demand for this compound will stay strong. Technology trends in energy storage, displays, and custom polymers also draw on precisely halogenated benzenes. To keep up, chemists focus on greener synthesis, renewable feedstocks, and tighter recycling. Regulatory agencies plan stricter tracking, pushing producers toward better reporting and safer packaging. Innovation will keep spinning from bench to production plant. Science moves fast, but smart choices in safety and sustainability shape which molecules remain valued tools for the future.

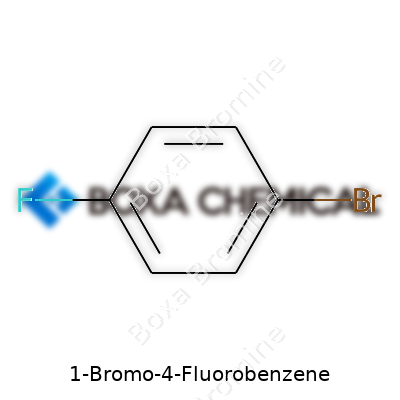

Understanding 1-Bromo-4-Fluorobenzene

Let’s break down the basics: 1-Bromo-4-Fluorobenzene has a straightforward formula—C6H4BrF. This simple ring, made of six carbons and four hydrogens, gives way to two special guests at the party: bromine and fluorine. One takes the first carbon, and the other sits on the fourth. No need to get tangled up in long chemical names to see how straightforward this molecule looks on paper.

Learning from Organic Chemistry

In my college chem labs, compounds like 1-Bromo-4-Fluorobenzene weren’t just textbook exercises. Our professor always hammered home the importance of understanding how atoms get swapped in and out of aromatic rings. It’s more than just lines and letters; each formula nods to the behavior of the molecule. The fluorine brings up the molecule’s reactivity, making it useful when chemists want more than just plain old benzene in reactions. Bromine, on the flip side, hands us some flexibility for further transformations.

Practical Applications Show Up in Real Life

In pharmaceuticals, tiny tweaks to a ring can change a drug’s whole story. Medicinal chemistry relies on swapping these halogens in and out. A ring that looks like C6H4BrF might show up as a building block for molecules that target disease at the molecular level. Its formula tells researchers exactly what’s inside the flask, helping prevent costly mistakes.

Even outside medicine, the pattern shows up in agrochemicals and materials science. That mix of bromine and fluorine on the benzene ring affects melting points, stability, and reactivity in ways that one or the other alone can’t pull off. Companies in crop protection or in designing new polymers pay close attention here, looking for better performance or safer handling.

Getting the Formula Right Matters

Mixing things up in a chemistry lab taught me early on: wrong formulas mean trouble. A lab partner once grabbed a similar but not quite identical compound for a reaction, and everything went sideways. Yields dropped, and purification became a headache. Now, with chemical formulas, you dodge mistakes. One letter off, and you end up with another molecule, not what the synthesis calls for.

Supporting Accuracy in Chemistry Classrooms and Labs

Schools and research labs do best when chemistry basics are nailed down early. Teaching the meaning behind formulas like C6H4BrF isn’t about rote memorization; it’s about building trust in the information chemistry relies on. Lab safety depends on it. Companies rely on these formulas to comply with regulations, avoid toxic byproducts, and track their supply chains. One error in the supply process can mean a product recall, regulatory headaches, or something far worse.

Building Better Habits in Chemical Literacy

I keep seeing the benefits of accurate, clear formulas. Electronic lab notebooks, software for chemical inventories, and even regulatory filings use these details. Whether I’m helping a high school student or consulting for a startup, the right structure—the correct formula—makes chemical communication faster and more reliable. That’s a lesson that keeps giving back. C6H4BrF, spelled out and properly understood, creates a common language everyone in science can trust.

Core Roles in Pharmaceuticals and Agrochemicals

1-Bromo-4-Fluorobenzene lives at the intersection of modern science and practical application. Big pharma leans on this compound. Its chemical structure—a benzene ring with both a bromine and fluorine atom—sets it up as a strong building block. Chemists feed it into reactions to make more complex molecules, especially those destined for drug discovery. Swapping out hydrogen atoms on a benzene ring and replacing them with groups like bromine and fluorine helps researchers fine-tune a drug’s ability to reach targets in the body. Subtle tweaks can change a molecule’s potency, safety, or how long it lasts in your system. I once worked on a research project where just changing a single atom—such as swapping a hydrogen for fluorine—changed how a potential cancer treatment behaved inside cells. The difference in activity from one small switch can feel like night and day.

Agrochemical makers rely on 1-Bromo-4-Fluorobenzene, too. Growing food for billions takes carefully engineered herbicides and fungicides. The compound helps chemists lay down the backbone for molecules that ward off pests without harming crops or the environment. Reliable supply lines for these chemicals support higher food yields and more resilient farms.

Materials Development: Electronics and Polymers

If you look inside a smartphone or a computer, you’ll find plastics and chips that started life in a chemistry lab. Specialty polymers often owe their slick properties to building blocks like 1-Bromo-4-Fluorobenzene. The bromine and fluorine atoms fiddle with the physical and electrical traits of plastics, making them tough enough for gadgets or smooth enough for coatings that resist grime. Fluorinated polymers, in particular, block moisture and chemicals. This makes them a go-to for protective gear, pipes, and parts that deal with extreme conditions.

In electronics, 1-Bromo-4-Fluorobenzene opens doors for making complex organic semiconductors. Layering organic molecules with just the right properties creates circuits for OLED screens and solar panels. Rising demand for smaller, smarter, and more efficient devices keeps the market for these specialty chemicals busy.

Supporting Synthesis and Research

Lab benches around the world keep 1-Bromo-4-Fluorobenzene close at hand. It’s a popular choice for Suzuki coupling reactions—a chemical method that links up two aromatic rings. These linkages shape the foundation for pharmaceuticals, dyes, pigments, and advanced materials. The compound works well because bromine leaves the ring during the reaction, while the fluorine controls the molecule’s overall reactivity. That kind of chemical control lets researchers design molecules with predictability and precision. Three years ago, my own experiments benefited when I switched to this compound. The reactions finished faster, and the end product was cleaner, which cut down on time spent purifying results.

Pursuing Safer and Greener Chemistry

Even with all its benefits, 1-Bromo-4-Fluorobenzene asks for respect. Brominated and fluorinated compounds can be tough to break down. Careful handling and disposal routines matter, both for worker safety and for protecting waterways. Europe has stepped up with tighter regulations on some of these chemicals, nudging companies to keep finding new, greener routes. Researchers are chasing alternatives that work as well but break down easier, without sticking around for decades in the environment.

Staying current with advances in chemistry, manufacturing, and regulation builds a safer, cleaner future. As the global conversation shifts toward sustainability, the challenge lies in balancing progress with responsibility, so breakthroughs come with fewer trade-offs for health and the planet.

Understanding 1-Bromo-4-Fluorobenzene

1-Bromo-4-fluorobenzene falls into a group of halogenated aromatic chemicals. It doesn’t have the friendly face of an everyday household item. Small labs and chemical plants value it as a building block for synthesizing pharmaceuticals and specialty products. Once you crack open that bottle, though, it demands a little respect and some good habits.

Sensible Storage Practices

The first thing with 1-bromo-4-fluorobenzene is keeping it away from heat. This stuff will vaporize and mess with indoor air if left in a warm, open spot. My own memory of sticking halogenated reagents beside a sunny window—and dealing with the hospital-grade smell later—still makes me roll my eyes. The right spot tends to be a cool, dry cabinet, out of bright light and heat sources. Think about sturdy shelving, not loose garage corners.

Most people use tightly sealed, glass containers. The bromo and fluoro groups have some real reactivity, so avoid storing it near acids, bases or oxidizers. I've seen accidental spills turn into hazardous mix-ups when people store everything on shared shelves. A separate flammable-liquid cabinet with clear labeling makes a big difference.

Personal Safety Around 1-Bromo-4-Fluorobenzene

The smell alone signals that this isn’t water. Even a splash on your skin can bring out redness or itching, so gloves aren’t optional. Splash-proof goggles block the toughest part — fumes that sting your eyes in seconds. In a pinch, I've had to borrow a friend’s backup goggles after rushing a transfer. Shortcuts just mean sore eyes or a trip to the sink.

Ventilation also matters. Most workplaces have fume hoods, but home experimenters sometimes think an open window is enough. Fumes build up, and the headache isn’t worth it. Turn the vent on and stick to small batches.

What Happens in Case of Spills or Accidents?

Spills should never be wiped with bare hands or basic kitchen towels. Use dedicated spill kits — usually pads and granules that soak up and bind organic chemicals. Place used absorbents in a clearly labeled hazardous waste bin. I’ve watched new lab techs panic and grab water, only to spread the mess further. Fast action with proper tools saves time and improves safety.

Safe Transport and Disposal

If transport becomes necessary, the right container means everything. I never skimp on secondary containment (spill trays within cardboard boxes), even for short trips inside a building. Both DOT and local fire codes set clear rules here for anyone moving chemicals on public or private roads.

Disposal lands in hazardous waste territory. Pouring leftovers down the drain or regular trash escalates risk for others and leads to hefty fines. Registered chemical waste services take care of these leftovers safely, and most sites provide documentation for peace of mind. From experience, a quick call to the waste department clears up any guesswork.

Investing in Training and Planning

Routine training helps everyone remember the right steps, even for chemicals that seem low-key or familiar. Label updates, monthly checks of storage areas, and open discussion about near-misses can prevent the small mistakes that cause big headaches. Thoughtful storage and handling build a culture of safety and help protect both people and research goals.

Understanding the Chemical

1-Bromo-4-fluorobenzene draws attention mainly among people who work in labs or chemical plants. If you ever spent time handling chemicals, you know how these names come with a need to pay close attention. This compound shows up as a colorless liquid with a strong chemical smell, used in organic synthesis for making pharmaceuticals and advanced materials. The safety concerns around it do not come from it being widely used, but from handling a compound that combines bromine and fluorine with a benzene ring. Anyone who's cracked an organic chemistry textbook can recognize the risk just from the structure. Benzene derivatives have a long history of causing trouble for both workers and the environment.

Assessing Real Risks

The question about toxicity lands right where it matters: skin, eyes, lungs, and what could happen after long-term exposure. Direct skin contact from a splash in the lab may cause irritation or even a rash. Splashes to the eye may result in burning and could need medical attention. Breathing in fumes or mist, especially in a space without good ventilation, puts you at risk for headaches, dizziness, or worse respiratory issues. Anyone who has worked with volatile aromatics will recall that “just a bit” can be enough to spoil your day.

Animal studies and lab reports show its acute toxicity stays within the range that triggers workplace regulations. The oral LD50 in rats, which measures the dose that kills half of a group of exposed animals, points to moderate toxicity. Data from GHS (Globally Harmonized System) labels the chemical as harmful if swallowed, toxic to aquatic life, and able to irritate skin and eyes. In my experience, these hazard statements mean personal protection matters: gloves, goggles, and lab coats should not gather dust in your workspace.

Environmental Concerns

Chemicals containing halogens like bromine and fluorine do not break down quickly in nature. Release into drains or the wrong disposal can poison aquatic life far downstream from where it first left the bottle. Safety sheets advise containment and careful clean-up, not just for personal safety but to prevent slow, cumulative poisoning of water and soil. After all, accidents happen, and the safest labs I worked in always posted “No disposal in sink” signs for aromatic halides like this one.

Best Practices

Getting too comfortable spells danger. I’ve seen even cautious folks reach for “just a little more” without tightening the cap or setting up ventilation. Chemical fume hoods, gloves that resist solvents, and sturdy eye protection hold value here. Training new team members or students to treat every aromatic halide with respect cuts risks in ways that written rules alone never fully cover.

Anyone storing or working with this chemical should make sure all containers are tightly sealed and clearly labeled. Spill kits, eyewash stations, and a plan for what to do if things go wrong mean the difference between a near-miss and real harm.

Moving Toward Safer Labs

No one expects a casual user to buy or handle 1-bromo-4-fluorobenzene, but those in the industry or academia need more than the basics. Regular safety briefings, up-to-date Material Safety Data Sheets, and easy access to proper disposal channels support healthy workplaces and protect the environment. Veteran chemists who value their health and their jobs tend to treat stuff like this with steady, cautious hands and a deep respect for the rules.

Why Purity Actually Matters

Every chemist has faced a big gap between “good enough” and “actually reliable” in their work. Trying to nail down the quality of 1-Bromo-4-Fluorobenzene underlines that point right away. Whether the chemical lands in a pharma lab, an agrochemical run, or maybe an electronics plant, the stuff running through those beakers transforms industry—not through mystery, but because it’s predictable.

Real-world output hinges on getting materials that don’t bring unknowns with them. Purity isn’t just a lab talking point. Traces of leftover reagents, unreacted starting chemicals, or stray water molecules knock results off target—bad for safety, bad for quality, surprisingly bad for budgets. Industry publications have flagged this for years. LGC Standards and Alfa Aesar, two recognized suppliers, commonly sell this compound at purities no less than 98%, and most published research expects 99% or higher.

Common Specs and Their Relevance

Actual material specs—often written right on the container label—generally look for “purity by GC” or “purity by HPLC.” For 1-Bromo-4-Fluorobenzene, figures like 98%, 99%, and occasionally 99.5% jump out. Rest isn’t some harmless filler. Common contaminants show up as halogenated benzenes, trace acids, or left-over solvents.

I’ve seen labs grind to a halt over a single nasty contaminant, which eats up research hours and contaminates expensive equipment. I remember a fellow grad student’s experiment tanking three times in a row for no clear reason, losing an entire month’s work until the supplier’s certificate of analysis finally pointed to a persistent impurity.

Verification Isn’t Just for Textbooks

Most serious work asks for a certificate of analysis (CoA). Beyond a simple percentage, these documents list test methods, batch-lot numbers, and breakdowns of detectable impurities. If you’re planning precision synthesis, whether in a new drug or the creation of a specialty chemical, this documentation isn’t busywork. It stops mistakes before they start.

Reliable suppliers update these CoAs with every batch. Buyers need that confidence, especially with evolving safety standards and regulatory audits. If the company can’t hand over a recent, full trace, that’s a warning sign.

Room for Industry Improvement

Chemical supply chains occasionally sacrifice thorough purity testing to cut costs. That shortcut may not set off alarms for routine experiments, but it wreaks havoc in quality control, product shelf-life, and downstream yields. Manufacturers who skip robust traceability to speed shipments or lower the price do their customers a disservice.

Whole industries call for tighter standards and more transparency. There’s still too much variance batch-to-batch, even among big-name chemical distributors. Regular audits, open communication about possible contaminants, and real investment in analytical testing can bridge that gap.

Solutions and What Buyers Should Ask

Anyone buying 1-Bromo-4-Fluorobenzene needs to look past marketing terms like “high purity.” Ask for recent, traceable certificates. Push for specifics on moisture content, volatile residue, and the actual detection methods used. Don’t treat purity as a checkbox; insist on supporting data.

Some labs now go as far as running their own additional analyses using NMR, GC-MS, or Karl Fischer titration for water. While this costs more up front, it saves immeasurably in preventing failed experiments and hazardous incidents.

By shifting the norm from “meets spec” to “here is the proof,” suppliers and users build trust that drives discovery forward—and keeps people, products, and research safer and stronger in the long haul.